Page 27

English

General Description

7 PRODUCT DESCRIPTION

7.1 Introduction

The VLH units are water chillers /air-water heat pumps

provided with hermetic scroll compressors with two

refrigeration circuits.

These units are fit for cooling and heating intermediate

7.2 General specifications

The VLH units are supplied complete and provided

with all connecting pipes for the refrigerant and inter-

nal wiring.

The refrigeration circuit of each unit undergoes a pres-

sure test, is drained, vacuumised, dehydrated and

filled with refrigerant, and includes the necessary oil.

Once assembled, each unit is subjected to a complete

final testing and the correct operation of all refrigera-

tion circuits is checked.

The base and the frame of each unit are made of very

thick galvanised sheet, and are secured by screw and

stainless bolts. All panels are secured by screw and

tropicalised steel bolts, they can be disassembled for

easy access to internal components.

All galvanised steel parts are painted with white poly-

ester resin (RAL 9001), to ensure the resistance of the

unit to corrosion and weather agents over time.

7.3 Compressors

These units are provided with hermetic scroll compres-

sors, with built-in motor protection.

Compressors are mounted on shock absorbers to

reduce vibrations. Motors are of direct start-up

type,cooled by the sucked refrigerant gas.

Thermistors protect the windings from any overtem-

peratures and the electronic control checks that the de-

livery temperature is within the permissible range. The

capacity control, as well as the control of the delivered

cooling capacity, are always ensured by the electronic

control.

7.4 Refrigeration circuits

Each unit has two complete refrigeration circuits,

including: a service valve to fill the unit with re-

frigerant, shut-off valves, thermostatic expansion

valve, dehydrating filter, sight glass with humid-

ity indicator, a differential pressure switch for the water.

The outdoor VLC units are marked by the absence

of the evaporator, and are equipped with shut-

off cocks on the suction line and on the liquid line, so

as to allow the connection of remote evaporators.

Furthermore, each circuit is equipped with safety devices

in accordance with PED 2014/68/EU: HP and LP pres-

sure switches, safety valves providing protection in case

of fire or malfunction of compressors.

7.5 Water heat exchanger

The evaporators are of stainless steel plate type.

Their thermal insulation is ensured by a thick flexible

closed-cell heat-insulating jacket. Furthermore, the

frost protection is ensured by electric heaters.

These exchangers can work at pressures up to 10 bar

on the hydraulic side and 45 bar on the refrigerant

side.

The hydraulic connections to the evaporator are of 2”

1/2 Victaulic type on 704 – 804 units and 3” Victaulic

type on 904 – 1204 units.

fluids (glycoled water), for air-conditioning applica-

tions in industrial processes.

These units can be installed outdoor on the roof of a

building or at ground level.

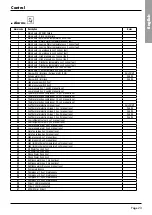

This series includes the following versions:

Version (STD/HSE

1

)

Description

VLH Base Low Noise version (STD

2

)

VLH Low Noise version (L)

VLH Extra Low Noise version (S)

VLH High Temperature version (HET)

Air condensing heat pumps, using

R410A refrigerant.

1

High efficiency Units (HSE) with inverter fans

2

A High Pressure Fan (HPF) version is available

The corresponding condensing unit version (VLC) is available

Available options:

Options

Description

VLH/D

The heat recovery is carried out by a desuperheater mounted on the compres-

sor’s discharge line.