Page 30

General Description

7.8 Electric power supply and

control system

The control compartment contains and electronic card

with keyboard and a display for working parameters,

alarms, if any, and operating blocks.

It is complete with remote control switches and pro-

tection fuses for the motors of compressors, fans and

pumps.

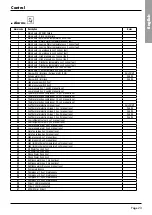

7.9 Accessories

List of available accessories, provided separately, to

be mounted on site by the installer:

Water flow switch

Prevents the operation of the unit when the chilled fluid

is insufficient. It is advisable to install a flow switch, to

ensure the correct operation of the unit.

Water filter

Filter to be mounted on the suction side of the water

heat exchanger.

Antivibrating supports (AVM)

Isolating spring supports, equipped with bolts for fas-

tening to the base. They are supplied separated from

the unit and must be mounted on site by the customer,

at his own expense.

Fan speed regulator

The speed regulator of the fans is mounted as a stand-

ard accessory for the Extra Low Noise units, and is an

optional accessory for the Standard and Low Noise

units. The fan speed is controlled in order to work at

a low room temperature, and allows the unit to work

down to a room temperature of –18°C.

The control can be of the pressostatic step type, with

temperature correction, or of continuous type (under

pressure), with electronic regulator. The regulator is of

electronic type only for the Extra Low Noise versions.

Wire-type remote control kit

The kit includes a remote control for wall mounting,

complete with 3m-long connecting cable, and installa-

tion manual and a transformer.

For longer distances (i.e. up to 50m) you can use a

multipolar cable of minimum section (0.25mm). Con-

ductors should be connected directly and according to

the diagram with accompanies the installation instruc-

tions.

Remote wall terminal

Makes it possible to check the unit through a remote

terminal, up to a maximum distance of 200 meters.

RS-485 serial card (for MODBUS or

LONWORK or BACNET )

A communication interface makes it possible to control

and manage the unit from a local station, with RS485

connection, up to a distance of 1,000m.

It is possible to obtain the remote control and the man-

agement, by inserting the control into the management

plant of the building.

Hydronic module

The Hydronic Module, to be installed on site at the

Customer’s expense, is a hydraulic package which

includes all the components required for the fluid dis-

tribution system. It has been designed for outdoor in-

stallation, on the roofing of the building, rather than

directly at the ground level.

The Hydronic Module is enclosed in its own case and

includes:

n

an inertial tank

n

a single or double pump for standard head or high

head

n

the expansion tank

n

a water filter installed near the suction of the pump

n

a pressure gauge

n

shutoff valves for filter maintenance purposes

n

a safety valve, calibrated at 3 bar

n

an automatic air relief valve

n

fill and drain valves

n

thermal insulation for piping and hydronic compo-

nents

n

a switchboard (protection class IP54) provided with

main disconnecting switch, contactors and fuses for

the pump and the electric heaters, if any

n

antifreeze electric heater (optional)

n

kit of antivibrating devices (optional) to be used if the

appliance is to be installed on the refrigerator

n

cascade start-up sequencer (up to 4 parallel units).