Page 62

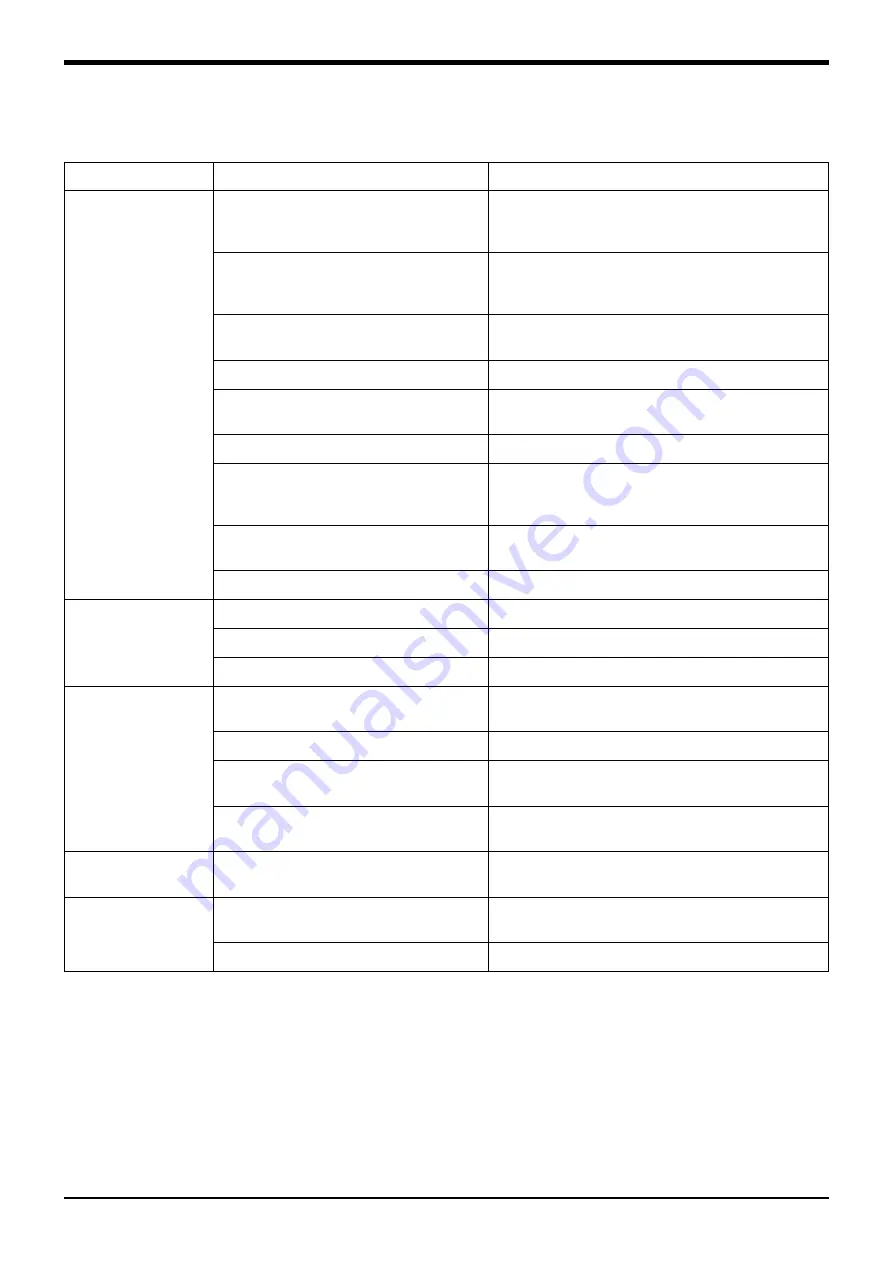

Troubleshooting

Anomaly

Cause

Operation

One or both com-

pressors are not

working.

Breaking of the electric circuit.

Check the electric circuit and detect any

ground dispersions and short circuits. Check

fuses.

Intervention of the HP pressure

switch.

Reset the pressure switch and the control panel

and restart the appliance. Identify and remove

the cause that enabled the pressure switch.

The fuse of the control circuit is bro-

ken.

Check for ground dispersions and short circu-

its. Replace fuses.

Loosened terminals.

Check and tighten.

Halt caused by thermal overload of

the electric circuit.

Check the operation of check and safety devi-

ces. Identify and remove the cause.

Wrong wiring.

Check wiring of check and safety devices.

The line voltage is too low.

Check voltage. If problems regard the system,

solve them. If they are caused by the distribu-

tion network, inform the Energy Distributor.

Short-circuit of the compressor’s mo-

tor.

Check the continuity of the winding.

Seized compressor.

Replace the compressor.

Activation of the LP

alarm, stop of the

unit.

Gas leak.

Identify and remove the leak.

Insufficient charge.

Refill.

Failure of the pressure switch.

Replace the pressure switch.

Activation of the HP

alarm, stop of the

unit.

Failure of the pressure switch.

Check the operation of the pressure switch, re-

place it if defective.

The delivery valve is partially closed.

Open the valve and replace it, if faulty.

Substances with condensable gases

in the circuit.

Drain the circuit.

The fan of the condenser is stopped.

Check cables and motor. If defective, repair or

replace.

The liquid line is too

hot.

Insufficient charge.

Identify and remove the cause of the loss of

charge and refill.

Frosting of the li-

quid line.

The valve of the liquid line is partially

closed.

Check that valves are open.

The liquid filter is clogged.

Replace the cartridge or the filter.