10

Systematics, Inc. West Chester, PA. 19380

CONTINUOUS WELDING

ON ALUMINUM

(Optional Nylon liner and 100%

Argon shielding gas are required

)

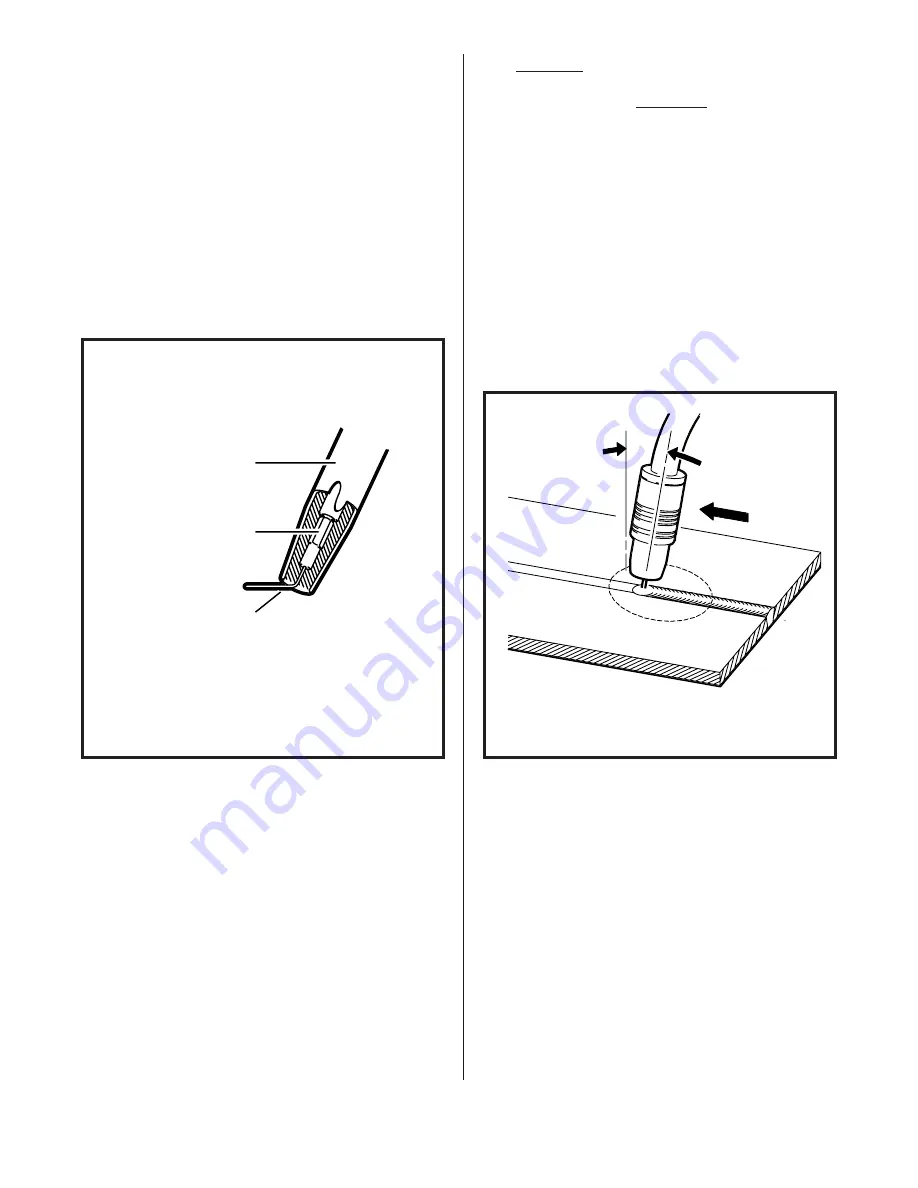

1. Trim the electrode wire, leaving

approximately 1 inch stickout

beyond the end of the nozzle.

Bend the wire over as shown, to

allow for a scratch start. The

contact tip should be recessed

inside the nozzle approximately

3/8 inch. This helps prevent the

welding wire from burning back

to the contact tip.

2. DO NOT spray any anti-spatter

material on the torch or base

metal and DO NOT attempt to

lubricate the aluminum wire in

any way. Weld contamination

will occur unless the wire, base

metal, torch and work area are

kept clean.

3. Bring the torch nozzle to 1/2 to

5/8 inch from the workpiece.

The recommended position of the

torch and direction of travel

for welding aluminum are shown

in the following illustration.

4. Follow steps 4 and 5 as in

"Continuous Welding on Steel".

FIG. 15. TORCH POSITION

FOR WELDING ALUMINUM

FIG. 14. NOZZLE ADJUSTMENT

FOR WELDING ALUMINUM

ELECTRODE

WIRE

(1" STICKOUT)

NOZZLE

CONTACT TIP

(RECESSED 3/8")

SHIELDING GAS

10 DEGREES

WORK

DIRECTION

OF TRAVEL