2

Systematics, Inc. West Chester, PA. 19380

ELECTRODE

GAS NOZZLE

SHIELDING GAS

WORK

ELECTRODE

GAS NOZZLE

SHIELDING GAS

WORK

Welder controls are simple and

clearly marked. The output voltage

is controlled by a twelve position

tap switch, providing 4 TIG and 8

MIG voltage selections. Wire feed

speed is controlled by the wire

speed potentiometer.

SPECIFICATIONS

PART NUMBER:

PBE180

INPUT POWER REQUIREMENTS:

Voltage

208/230

Phase

single phase

Frequency

50/60 hertz

Current

22/20

OUTPUT POWER

@ 60% Duty Cycle:

180 Amps

DUTY CYCLE TIME PERIOD:

10 minutes

OPEN CIRCUIT VOLTAGE:

18 - 35 volts DC

ARC VOLTAGE:

14 - 26 volts DC

WELD CURRENT RANGE:

30 - 180 amps

WIRE TYPES:

mild steel,

Recommended (for steel)

ER70S-6

stainless steel, aluminum,

bronze, flux cored,

flux cored - gasless

WIRE SIZES:

.023" - .045" steel,

3/64" aluminum,

(.023" - 3/64" alum. w/spool gun)

.030" - .035" bronze,

.030" - .045" flux cored

(gas shielded or gasless)

Recommended Size: Aluminum

.035

Others

.030

SHIELDING GASES:

For Steel

CO2 or Argon/CO2 mix

Recommended (for steel) 75% Argon/

25% CO2

For Aluminum, Bronze

Argon

For Stainless Steel

Argon/2% Oxygen

For Flux cored

CO2 or

Argon/CO2 mix

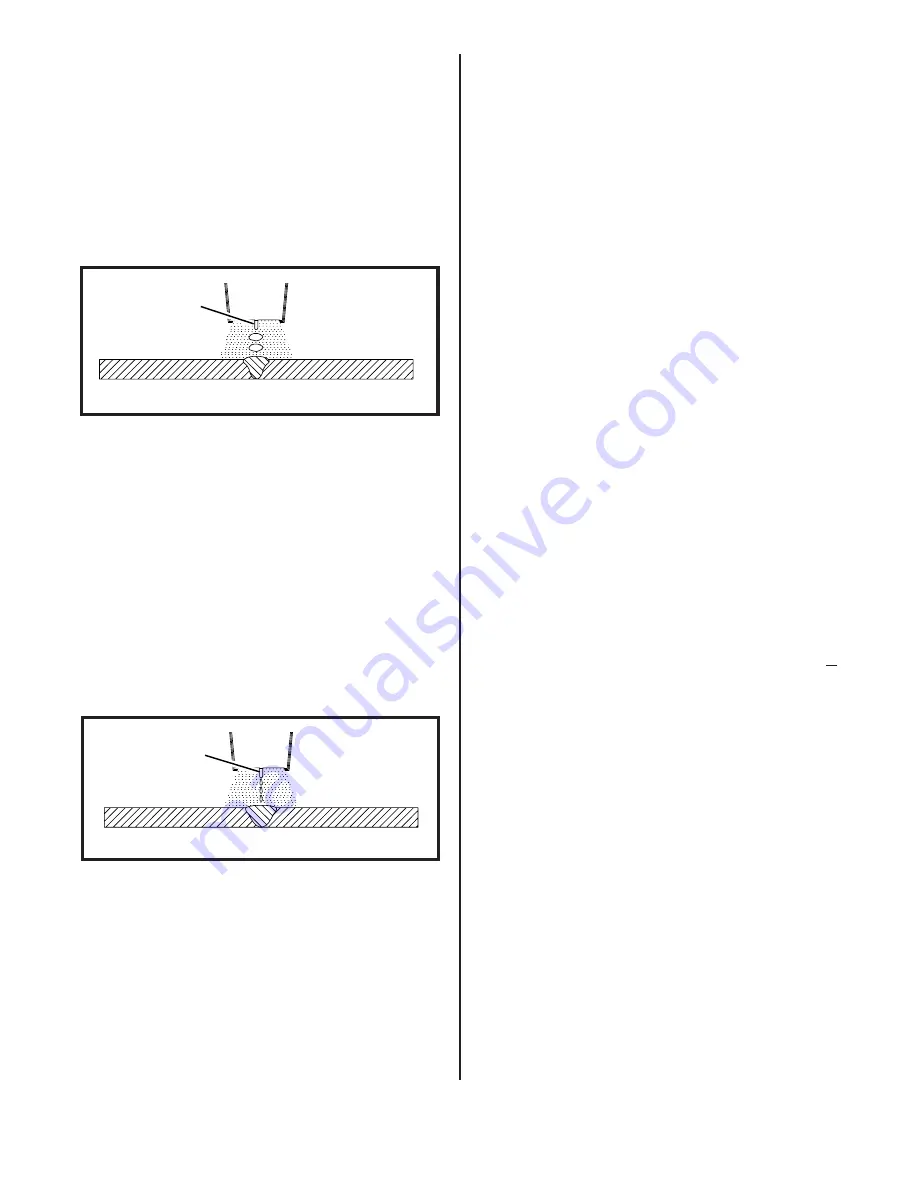

GLOBULAR TRANSFER

Globular transfer occurs at the

intermediate range of 22 to 24 arc

volts, depending on wire size. As

the name implies, the transfer

takes place in the form of irregu-

larly shaped globules. Globular

transfer is useful in cases where a

lower heat input than that of true

spray is required.

SPRAY TRANSFER

Spray transfer occurs at 22 to 32

arc volts, depending on wire size.

The length of the arc is held

constant by the voltage available.

The higher voltage and current

causes the electrode wire to melt

off before touching the workpiece.

The molten metal crosses the gap to

the workpiece in a spray form.

Spray transfer is used in the down-

hand position and provides higher

deposition rates than short arc

transfer or globular transfer.

DESCRIPTION

The PBE180 consists of a combina-

tion MIG welding power source and

wire feed unit, a MIG torch with 10

foot cable, a ten foot work cable

with clamp, a twenty foot power

input cable, a gas regulator -

flowmeter, a torch accessory kit,

and a built-in cylinder rack and

industrial wheel kit.

FIG. 3. GLOBULAR TRANSFER

FIG. 4. SPRAY TRANSFER