PORTABLE

COLLARING SYSTEM

15

PLUS 115

7. TAKING THE MACHINE INTO OPERATION

Creating a collar with your PLUS 115 and completing the joint is simple. Because it is a

new process we recommend you to read the following instructions carefully and then

practice a few times on some pieces of scrap tubing.

NOTE!

¨

Before using, check that the supply voltage agrees with the rated voltage

specified on the tool.

7.1 ASSEMBLY OF THE PLUS 115 DRILLING UNIT TO T-65

1

2

3

5

4

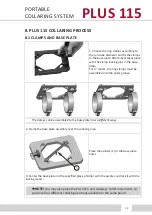

Drilling unit and T-65: 1. T-65 machine, 2. Push rods of the T-65, 3. Drilling unit of PLUS

115, 4. Attachment screws of drilling unit (to T-65 push rods), 5. Handle attachment screw.

Assemble the drilling unit to T-65 the following way:

1.

Remove the T-65 body screw and attach the drilling handle with (5) Handle

attachment screw.

2.

Attach the drilling unit bottom plate to T-65 push rods (2) with 2 M6x16 countersunk

socket head cap screws (4).

Test mobility of handle joints.