5

We decline any liability for damage caused by inappropriate repair attempts. Any damage

caused by inappropriate repair attempts will avoid all warranty claims.

Observing the conditions of use and the ranges of application of the present device will reduce the risk of possible

operational malfunction and contribute to extend the lifetime of your unit. Sand and other abrasive matters

contained in the liquid discharged will speed up the process of wearing and tearing and accelerate the drop in

performance.

If the unit is operated properly, it will not require any maintenance. Where applicable, you may clean the hydraulic

part from sediments and dirt. This can be done by counter-flushing the unit with clear water using a hose to be

connected through the pressure port of the pump. To remove tenacious dirt, the foot of the pump (8) can be

removed by loosening the screws located at the bottom of the pump. To avoid any hazard, any further

disassembly as well as the replacement of parts must only be done by the manufacturer or a by an authorised

service provider.

Water left in the pump may freeze in case of frost and thus cause considerable damage. Therefore, the pump

must be removed from the liquid being discharged and fully drained when temperatures are below the freezing

point of the liquid. Please store the pump in a dry, frost-protected place.

In the case of malfunction, you should first of all check whether it was caused by an operating error or some other

reason which cannot be attributed to a defect of the device - for instance a power failure.

The list below shows some possible malfunctions of the device, possible causes and tips on their elimination. All

the measures referred to may only be carried out with the pump being separated from the electrical mains. If you

yourself feel unable to eliminate any of these malfunctions, please contact the customer service department or

your point of sales. Any repair beyond the scope specified below must only be performed by qualified staff.

Please bear in mind that all warranty claims will become void in the case of damage caused by inappropriate

repair attempts, and that we decline any liability for any ensuing damage.

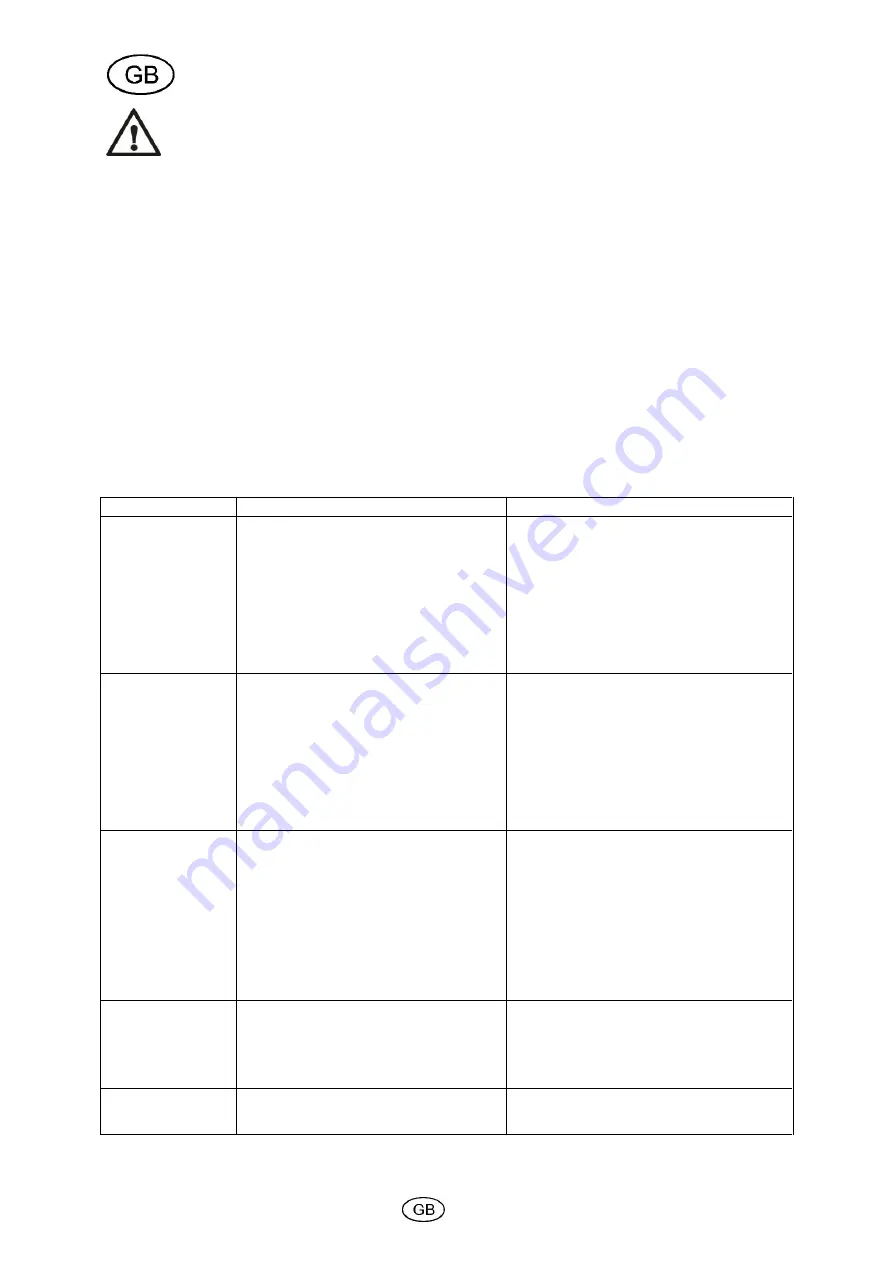

MALFUNCTION

POSSIBLE CAUSE

ELIMINATION

1. The pump is not

discharging any

liquid, the motor is

not running.

1.

2.

3.

4.

5.

No current.

Thermal motor protection feature has

triggered. (for information on operation with

liquids > 50°C, see the note in Technical data).

The capacitor is defective.

The pump wheel is blocked.

The floating switch is defective.

1.

2.

3.

4.

5.

Please use a device complying with GS (German

technical supervisory authority) to check for the

presence of voltage (safety information to be

observed!). Please verify the correct position of

the plug.

Separate the pump from the electrical mains,

allow the system to cool down, eliminate cause.

Please contact the customer service department.

Eliminate blocking of pump wheel.

Please contact the customer service department.

2. The motor is running,

but the pump is not

discharging any

liquid.

1.

2.

3.

4.

5.

The intake openings are clogged.

The pressure line is clogged.

Air penetrates into the pump body.

The min. suction level was fallen short of;

possibly incorrect setting of the floating switch,

motion of floating switch restricted, floating

switch defective.

Check valve (non-return valve), if present, is

blocked or defective.

1.

2.

3.

4.

5.

Remove possible congestion.

Remove possible congestion.

Start pump several times so that the entire air will

be driven out.

Make sure that the minimum suction level is not

fallen short of; if necessary, adjust floating switch

properly or make sure that it can move freely; in

the case of a defective floating switch, please

contact customer service.

Eliminate blocking of the check valve (non-return

valve) or replace, if damaged.

3. The pump stops after

a short time of

operation because

the thermal motor

protection feature

has triggered.

1.

2.

3.

4.

5.

The electrical supply does not correspond to

the information given on the type plate.

Pump or intake openings are blocked by

solids.

Liquid is too viscous.

Temperature of the liquid is too high.

Pump is running dry.

1.

2.

3.

4.

5.

Please use a device complying with GS (German

technical supervisory authority) to check the

voltage of the lines of the connection cord (safety

information to be observed!).

Remove possible congestion.

Pump may not be suitable for this liquid. If

feasible, the liquid should be thinned.

Make sure that the temperature of the liquid being

pumped does not exceed the max. admissible

value.

Eliminate causes of dry-running.

4. Intermittent or

irregular operation.

1.

2.

3.

4.

5.

Pump wheel obstructed by solid matters.

Refer to section 3.3.

Refer to section 3.4.

Mains voltage out of tolerance.

Motor or pump wheel defective.

1.

2.

3.

4.

5.

Remove solids.

Refer to section 3.3.

Refer to section 3.4.

Make sure that mains voltage matches that

indicated on the type plate.

Please contact the customer service department.

5. Water quantity

discharged by pump

is inadequate.

1.

2.

3.

Refer to section 2.1.

Refer to section 2.2.

Worn pump wheel.

1.

2.

3.

Refer to section 2.1.

Refer to section 2.2.

Please contact the customer service department.

12

Summary of Contents for EXTREMA 300/10 IX

Page 40: ...1 T I P 1 1 2 2 3 2 4 2 5 3 6 4 7 4 8 5 9 6 10 7 11 7 1 RCD FI 30 mA 38...

Page 42: ...3 5 5 1 5 2 1 5 3 5 4 2 3 4 5 4 40...

Page 43: ...4 13 5 5 6 6 FI 30 mA DIN VDE 0100 739 3 x 1 0 mm VDE 7 41...

Page 46: ...7 1 2 3 10 www tip pumpen de 11 PDF e mail service tip pumpen de 2012 19 EU 44...

Page 71: ...1 T I P 1 1 2 2 3 2 4 2 5 3 6 4 7 4 8 5 9 6 10 7 11 7 1 RCD FI 30 mA 8 69...

Page 73: ...3 5 5 1 5 2 1 5 3 5 4 2 3 4 5 4 13 71...

Page 74: ...4 5 5 6 6 Fl 30 mA DIN VDE 0100 739 3 x 1 0 mm VDE 7 230V T I P EXTREMA 50 C 72...

Page 75: ...5 8 8 1 1 2 50 C 3 4 5 1 GS 2 3 4 5 2 1 2 3 4 5 1 2 3 4 5 3 1 2 3 4 5 1 GS 2 3 4 5 73...

Page 77: ...7 10 www tip pumpen de 11 PDF service tip pumpen de EU EU 2012 19 EU 75...

Page 102: ...1 T I P 1 1 2 2 3 2 4 2 5 3 6 4 7 4 8 5 9 6 10 7 11 7 1 RCD 30 100...

Page 104: ...3 5 5 1 5 2 1 5 3 5 4 2 3 4 5 4 13 102...

Page 105: ...4 5 5 6 6 FI 30 DIN VDE 0100 739 3 x 1 0 VDE 7 230 T I P EXTREMA 50 C 103...

Page 106: ...5 8 8 1 1 2 50 C 3 4 5 t 1 2 3 4 5 2 1 2 3 4 5 1 2 3 4 5 3 1 2 3 4 5 1 2 3 4 5 104...

Page 108: ...7 10 www tip pumpen de 11 PDF service tip pumpen de 2012 19 EU 106...

Page 109: ...1 T I P 1 1 2 2 3 2 4 2 5 3 6 4 7 4 8 4 9 5 10 6 11 6 1 30 8 107...

Page 111: ...3 5 5 1 5 2 1 5 3 5 4 2 3 4 5 4 13 5 5 6 109...

Page 112: ...4 6 FI 30 DIN VDE 0100 739 3 x 1 0 VDE 7 230 T I P EXTREMA 50 C 8 110...

Page 114: ...6 1 2 3 10 www tip pumpen de 11 PDF service tip pumpen de 2012 19 EU 112...