Translation of the Original Operating Instructions

9

If the unit is not used over some extended period of time, the water in the pump ought to be fully drained. Please

allow the pump to dry completely in order to prevent corrosion. Likewise, the fuel tank and the carburetor should

be emptied, too. On the units with auto-lubrication, the motor oil should be drained as well. Prior to placing the

unit in storage, it should be cleaned thoroughly and afforded some kind of preservation, should this be advisable.

Please make sure that the device is stored in a dry and frost-proof place.

If the water pump is used to pump slightly dirty water, a residue can be left in the pump. Before storage, take in

clean water with the water pump, in order to clean it.Otherwise, the pump impeller may be damaged when it is put

in service again. To clean the pump, unscrew the drain plug (2) from the pump and drain the pump

thoroughly

Troubleshooting

We decline any liability for damage caused by inappropriate repair attempts. Any damage

caused by inappropriate repair attempts will avoid all warranty claims.

None of the remedial actions listed below must be performed with the engine running.

The list below shows some cases of malfunction of the device, possible causes and tips on how to eliminate

them. None of the remedial actions specified must be performed while the engine is running. If you yourself

should feel unable to remove a malfunction, please contact the customer service department or your point of sale.

Any repair beyond the scope specified below must only be performed by qualified staff. Always keep in mind that

damage caused by improper repair attempts will void any warranty claims and that we decline any liability for

ensuing damage.

Should any malfunction occur, please check first whether a faulty operation or any other cause is present, i.e. that

the malfunction was not caused by a defect on the side of the device, for instance by a lack of fuel.

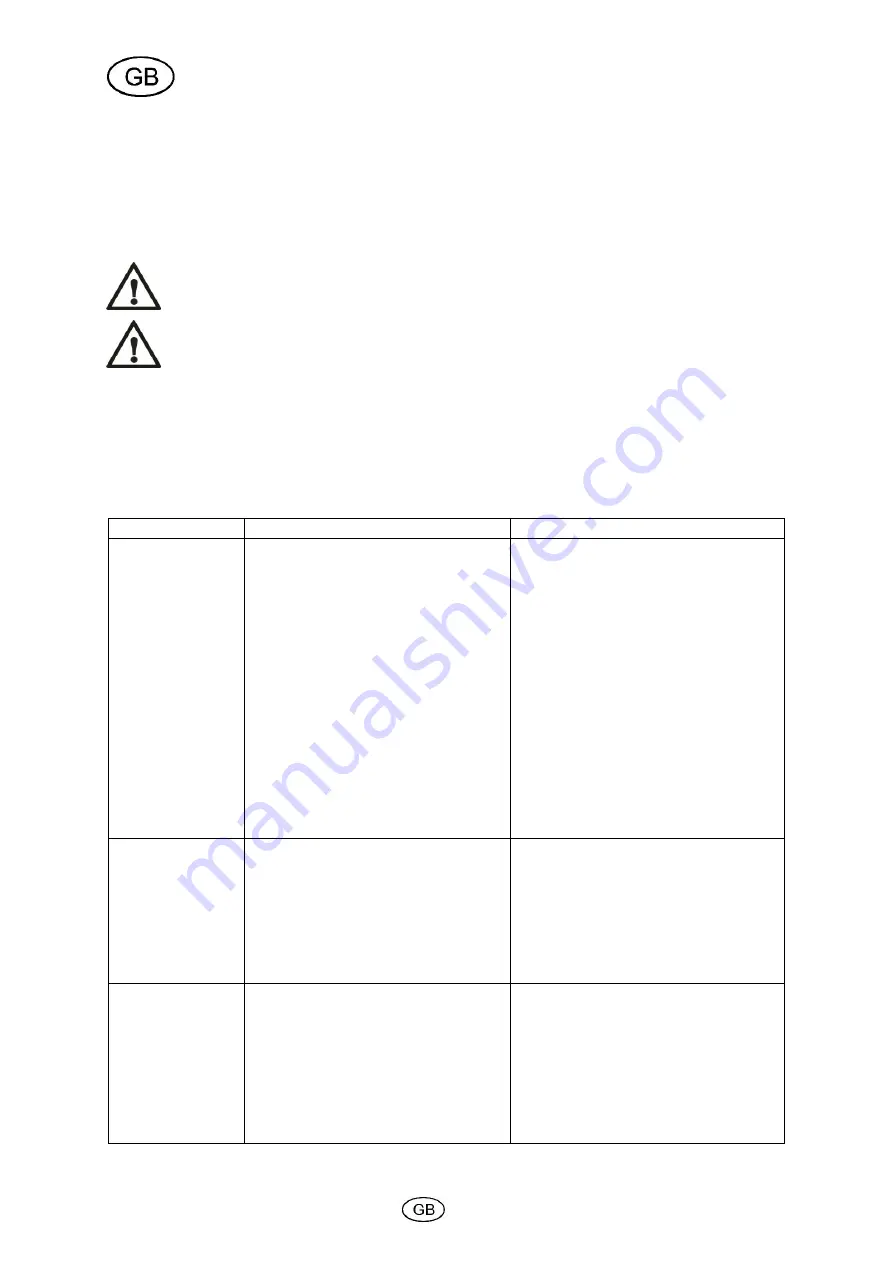

Malfunction

Possible cause

Elimination

1. The pump does not

discharge any liquid

at all or only a small

quantity, engine is

running.

1. Not enough liquid in the pump.

2. Leakage in the intake line.

3. Selected motor performance too low.

4. Filter at the inlet of the intake line is

clogged.

5. Intake line is clogged.

6. Pump wheel is blocked by foreign

matters.

7. Suction height and/or discharge height

too high.

8. Mechanical shaft seal is defective.

9. Pump wheel is not properly seated.

10. Pump wheel is damaged.

11. Motor is not running smoothly.

1. Fill pump housing through filling opening

with liquid.

2. Check intake line and its connections. If

required, seal connection parts of intake line

with Teflon tape. Replace intake line if it

shows damage which cannot be repaired.

3. Increase motor performance.

4. Clean filter.

5. Clean intake line.

6. Remove foreign matters.

7. Modify the arrangement so that the

suction height and/or discharge height do not

exceed the maximum value any longer.

8. Replace mechanical shaft seal.

9. Arrange pump wheel properly.

10. Replace pump wheel.

11. Contact customer service.

2. Vibration or loud

noise during

operation.

1. Suction height and/or discharge height to

high.

2. Intake line and/or pump wheel blocked

by foreign matters.

3. Instable installation.

4. Unit is not standing firmly.

5. Pump wheel is damaged.

6. Other technical defect.

1. Modify the arrangement so that the

suction height and/or discharge height do not

exceed the maximum value any longer.

2. Remove foreign matter.

3. Stabilise the installation.

4. Arrange unit firmly.

5. Replace pump wheel.

6. Contact customer service.

3. Motor does not

start or stop to run

during operation.

1. Lack of fuel.

2. Absence of ignition spark.

3. Clogged carburettor.

4. Clogged air filter.

5. On a model with auto-lubrication, the

auto-stop feature was activated because

the motor oil level had dropped below

required minimum.

6. Other technical defect.

1. Open fuel cock and/or fill in fuel.

2. Check ignition switch. If required, check

the spark plug.

3. Clean carburetor.

4. Clean air filter.

5. Top up motor oil.

6. Contact customer service.

20

Summary of Contents for LTP 500/30

Page 77: ...2 8 9 10 11 12 13 1 4 1 2 3 4 8 75...

Page 79: ...4 LTP 250 25 LTP 500 30 4 5 T I P 5 1 5 2 4 25 0 3 5 3 77...

Page 80: ...5 5 4 LTP 250 25 LTP 500 30 1 bar 0 1 MPa 3 bar 0 3 MPa 6 6 1 6 2 T I P 6 3 15W 30 78...

Page 81: ...6 5 ON 6 4 6 5 ON 6 6 79...

Page 82: ...7 20 10 6 7 OFF 6 8 7 80...

Page 84: ...9 7 5 a a 7 6 7 7 OFF 2 7 8 82...

Page 86: ...11 1 2 3 9 www tip pumpen de 10 PDF service tip pumpen de 11 84...

Page 110: ...Notizen notes note notas...

Page 111: ...Notizen notes note notas...