the crossed-out wheeled bin means that within the European union the product must be taken to separate collection at

the product end-of-life. this applies to your device but also to any accessories marked with this symbol. do not dispose of

these products as unsorted municipal waste.

In accordance with the wEEE directive concerning the environment, it is forbidden to abandon used electric or electronic

equipment or leave them at a standard public dump. the equipment must be taken to a collection point for treatment, re-

covery and recycling of EEE waste, or returned to its dealer on a 1 for 1 basis (one item of equipment bought for one item

of equipment taken back). the user is therefore taking an environmentally-friendly step and helping to preserve natural

resources and protect human health.

EXTENSION CORDS

Only use extension cords with three conductors ending in two-pin plugs and sockets with two holes and an earth pin that are suited to

the plug of the tool. when using a power tool at a considerable distance from the power source, use an extension cord heavy enough

to carry the current that the tool will draw. An undersized extension cord will cause a drop in line voltage, resulting in a loss of power

and causing the motor to overheat. use the chart provided below to determine the minimum wire size required in an extension cord.

Only round jacketed extension listed by laboratories should be used.

length of extension cord: up to 15 m

wire size: 3 x 2.5 mm2

Before using an extension cord, inspect it for loose or exposed wires and cut or worn insulation. Repair or replace any damaged or

worn cord immediately.

ELECTRICAL CONNECTIONS

your machine has a precision built electric motor. It should be connected to a power supply that is 230 V, 50 Hz. If your tool does not

operate when plugged into a socket, double-check the power supply characteristics.

the noise level of the machine is measured according to standards dIn En ISO 3744: 1995-11 and dIn En ISO 11203: 1996-07.

the values given are emission values calculated according to applicable standards and not values relating to use in the workplace.

Although correlation between those different emission levels does exist, this cannot be reliably used to determine whether additional

precautions are necessary. Factors with potential influence on the sound emission level in the workplace include the length of the

period of work, the size of the room and any other sources of noise (e.g. number of machines operating, other noisy work being carried

out at the same time). Acceptable exposure levels may vary from one country to another. For all these reasons, we would advise users

to wear equipment to protect their ears while using this machine.

Acoustic pressure level lpA: 74.9 dB (A) Acoustic pressure level lwA: 87.9 dB

uncertainty: 3 dB (A)

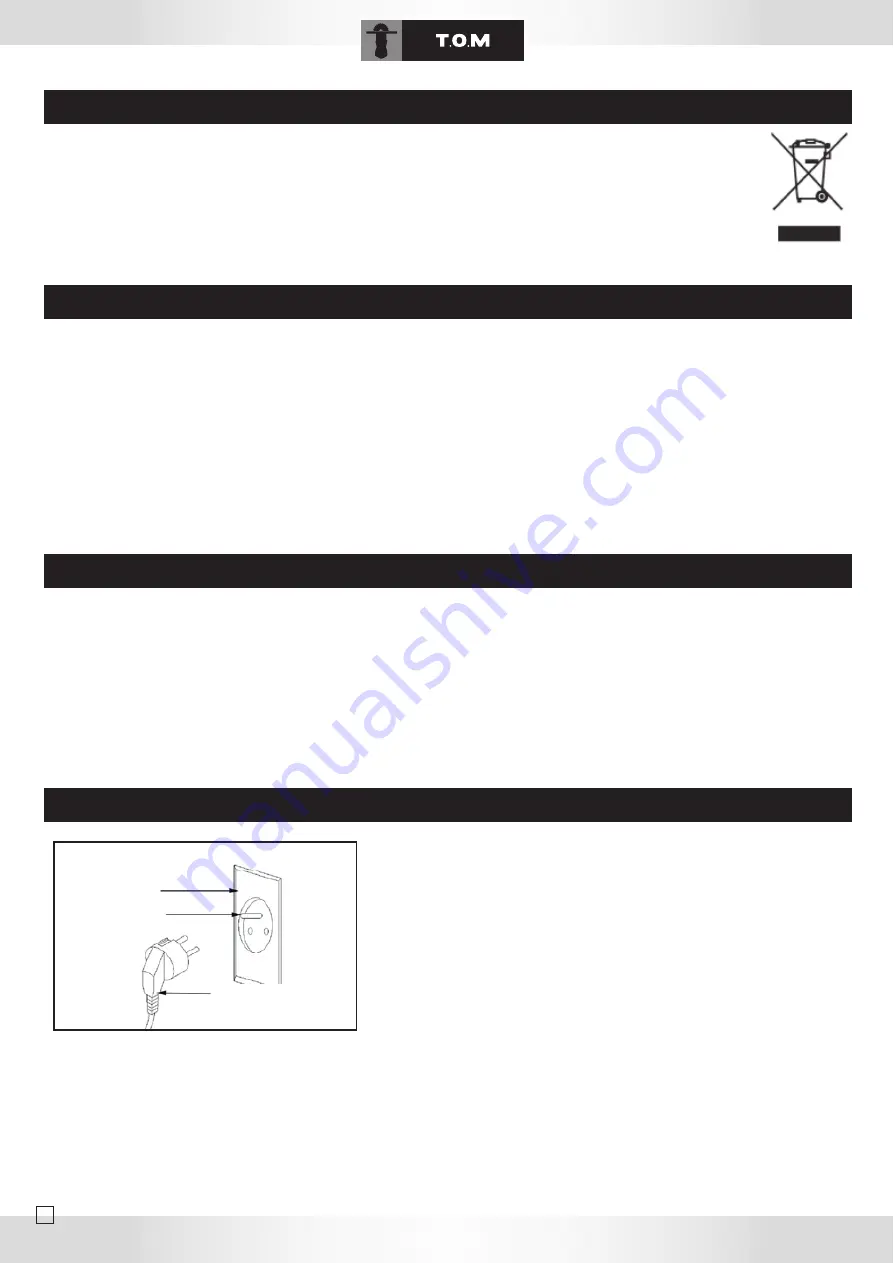

Earthing consists in connecting metal masses, that are liable to come accidentally

in contact with the current due to faulty insulation in an electrical device, to an earth

connection by means of a conductive wire. that earth connection, when used with

a differential circuit breaker, prevents electrical incidents. The current flows directly

into the earth and the power supply is automatically cut off. do not modify the sup-

plied plug. If it cannot be put into the socket, have an appropriate socket installed by

a qualified electrician. If the earth conductor of a machine is incorrectly connected,

this can lead to a risk of electric shock. the earth conductor is contained in green

insulation with a yellow line. If the power cord needs to be repaired or replaced, do

not connect the earth conductor to a live terminal.

Call in a qualified electrician or maintenance personnel if the earthing instructions are not fully understood or if in any doubt about the

correct earthing of the tool. If the power supply cable is damaged, it should be replaced by the manufacturer, the manufacturer’s after-

sales department or similarly qualified person in order to avoid any danger. Do not use a tool if its power cord is damaged. This tool is

designed to be used with a circuit containing a power socket. It is also equipped with an earthing pin.

ENVIRONMENT PROTECTION

CONNECTING THE MACHINE – ELECTRICAL CONNECTIONS

NOISE INFORMATION

EARTHING INSTRUCTIONS

12

Outlet with earth

earth

connection

Summary of Contents for GTB10

Page 2: ......