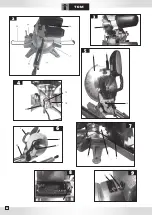

7.2 Making 90° crosscuts with turntable at 0° (Fig. 1-8)

For cutting widths up to 100 mm it is possible to fix the saw’s drag function with the knurled screw (14) in rear position. If the cutting width

exceeds 100 mm you must ensure that the knurled screw (14) is slackened and that the machine head (4) can be moved.

• Bring the machine head (4) to its upper position.

• Push the machine head (4) back by its handle (2) and affix in this position if necessary (depending on the cutting width).

• Place the piece of wood to be cut against the stop rail (7) and on the turntable (8).

• Secure the workpiece in position with the clamping device (17) on the base plate (9) to prevent the workpiece from moving

during the cutting process.

• Turn the release lever (1) to the left to release the machine head (4).

• Push the ON/OFF switch (3) to start the motor. Using the handle (2), push downward all the way through the work-piece with

uniform and light pressure.

• After the cutting process is finished, bring the machine head back to its upper (home) position and release the ON/OFF button

(3).

Caution! The resetting springs in the machine automatically raise the machine head. Do not simply let

go of the handle (2) after cutting, but allow the machine head to slowly lift up by applying slight coun-

ter pressure.

7.3 Precision adjustment of the stop for crosscut 90° (Fig. 1-4)

• Lower the machine head (4) and fasten in place with the safety pin (16).

• Slacken the tightening screw (13).

• Place the angular stop (a) between the blade (5) and the turntable (8).

• Slacken the counter nut and adjust the adjustment screw (19) until the angle between the blade (5) and the turntable (8)

equals 90°.

• Retighten the counter nut to secure this setting.

• Finally, check the position of the angle indicator. If necessary, release the pointer with a crosstip screwdriver, move to the 0°

position of the angle scale (15) and retighten the holding screw.

7.4 Making 90° crosscuts with turntable at 0°- 45° (Fig.2)

With the TSR-210 you can make right and left angular cuts from 0° - 45° to the stop rail.

• Use the handle (2) to set the turntable (8) to the desired angle the scale pointer on the turntable must coincide with the desired

angular setting (12) on the stationary base plate (9).

• Re-tighten the locking handle (10) to lock the turntable (8) into place.

• Cut as described under section 7.2.

7.5 Mitre cuts 0°- 45° and rotary table 0° (Fig. 1-2-9)

The TSR-210 can be used to make mitre cuts of 0°-45° relative to the machine bed on the left side.

• Lift the machine head (4) to its top position.

• Fix the rotary table (8) in 0° position.

• Undo the locking nut (13) and, holding the handle (2), tilt the machine head (4) to the left until the pointer (23) coincides with

the required angle dimension (15).

• Re-tighten the locking nut (13) and make the cut as described in Section 7.2.

Y

19

Summary of Contents for TSR-210

Page 2: ......

Page 30: ...5 13 22 6 3 4 5 30 1 6 2 35 6 31 7 15 35 8 9 23 19 16 7 11 5 2 24...

Page 31: ...VUE CLAT E 31...