42

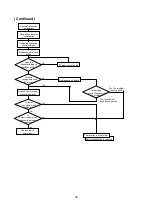

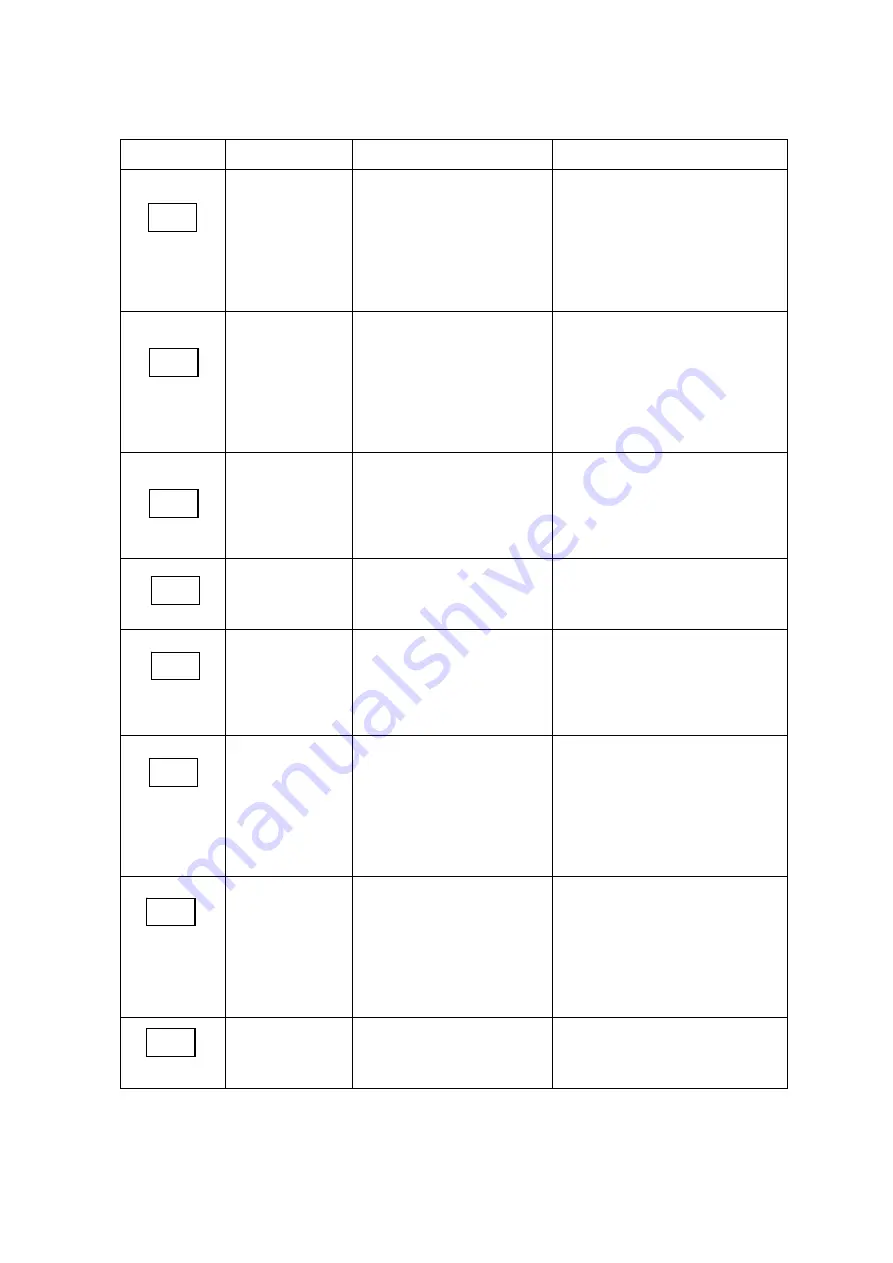

3.Manual Reset and Auto-Reset Operative Malfunction

INDICATION CONTENT

POSSIBLE

CAUSE

COUNTERMEASURE

Transient

over-current

starting machine

1. Motor coil short-circuit with

external casing

2. Motor connection wire

short-circuit with grounding

3. Transistor module

damaged

1. Examining motor

2. Examining wiring

3. Replace transistor module

Over-current at

acceleration

1. Acceleration time setting

too short

2. Improper V/F feature

selection

3. Applied motor capacity

exceeds inverter capacity

1.

Adjust acceleration time to

longer setting

2. Adjust to a proper V/F curve

3.

Replace and install another

inverter with appropriate

capacity

Over-current at

steady speed

1. Transient alteration of the

loading

2. Transient alteration of the

power supply

1. Examining the loading

configuration

2. Install inductor on the power

supply input side

Over-current at

deceleration

Deceleration setting too short

Adjust to use a longer

acceleration time

Over-current at

breaking

DC Breaking frequency,

breaking voltage, or

breaking time setting too

long

Adjust to reduce settings of

F_15, F_16, or F_17

Over-voltage at

operation/deceler

ation

1. Deceleration time setting

too short or inertial

loading too large

2. Power supply voltage

variation too large

1. Adjust to use a longer

deceleration time

2. Install a inductor on the power

supply input side

3. Increase the capacity of

inverter

Insufficient

voltage level at

operation

1. Power supply voltage too

low

2. Power supply voltage

variation too large

1. Improve power source quality

2. Adjust to use a longer

acceleration time

3. Increase capacity of inverter

4. Install a reactor on the power

supply input side

Heat-sink over

heated at

operation

1. Loading too heavy

2. Ambient temperature too

high or poor ventilation

1. Examining the loading

2. Increase capacity of inverter

3. Improve ventilation

OCS

OCA

OCC

OCd

OCb

OVC

LVC

OHC