0-003-2060-1 (EN)

2 (6)

Designation

Explanation

Part number

M400

modulating control signal or increase/decrease signal

880-0230-020

M400-S2

modulating control signal or increase/decrease signal and end point

switches

880-0231-020

The actuator

The step motor of the actuator turns a

screw via a gear wheel. The motor

receives a control signal from a

controller. The screw gets a linear

movement which moves the stem of the

valve.

Control signal

M400 can either be controlled by an

increase/decrease signal or by a

variable direct voltage.

If an increase/decrease signal is used,

the actuator normally moves inwards on

an increase signal and outwards on a

decrease signal, see Settings.

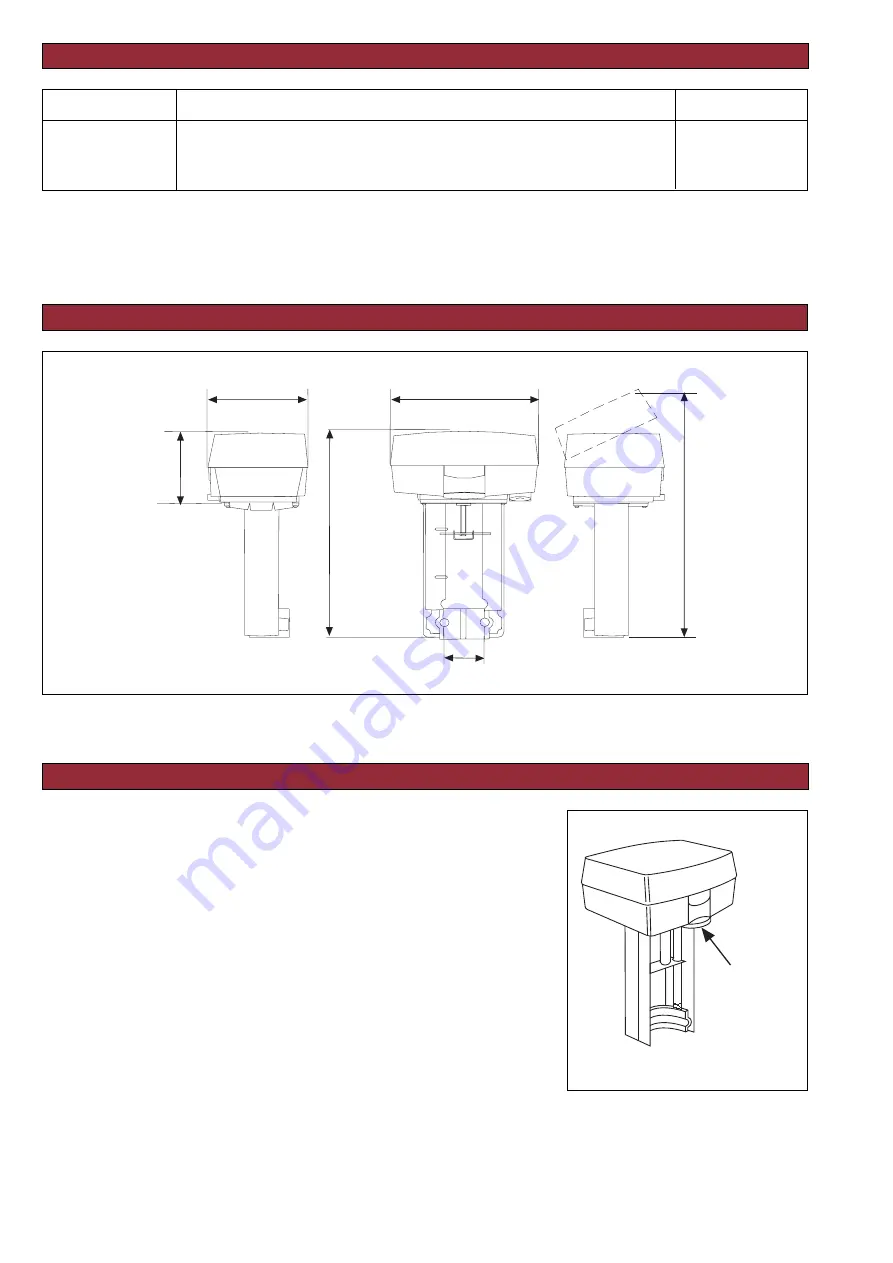

Manual operation

There is a manual operation handle on

the actuator, see figure 2. When it is

lowered, the motor stops. Then, the

actuator can be operated manually if

the handle is turned.

Position feedback

Forta actuators are equipped with a 2–

10 V DC position feedback signal,

where 2 V always corresponds to the

closed position and 10 V to the open

position.

End point switches

When actuators are controlled in

sequence, it is possible to use the end

point switches that have set positions.

They will toggle when the valve is fully

open or fully closed, respectively.

Manual

operation

handle

PART NUMBERS

FUNCTION

Figure 1

DIMENSIONS

173

44

315

82

242

117

(6.81)

(4.60)

(9.53)

(3.235)

(1.73)

(12.40)

Mått: mm

Dimensions: (in.)

Figure 2