10

6. Layout

1. Handle

2. ON/OFF switch

3. Locking button for ON/OFF switch

4. Locking lever for cutting depth setting

5. Power cable

6. Soleplate

7. Locking lever for miter setting

8. Locking screw for parallel stop

9. Scale for miter angle

10. Additional handle

11. Laser

12. Saw blade

13. Saw blade wrench

14. Connection for sawdust extractor

15. Motor casing

16. Parallel stop

17. Screw for securing the saw blade

18. Flange

19. Swing guard hood

20. Lever for swing guard hood

21. Guard hood

22. ON/OFF switch for laser

7. Before starting the equipment

Before you connect the equipment to the mains

supply make sure that the data on the rating plate

are identical to the mains data.

Always pull the power plug before making

adjustments to the equipment.

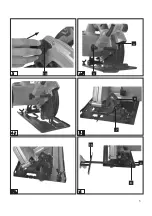

7.1 Assembly of the connection for clamping

extraction

Slide the connector in the device as shown in

Figure 3.

7.2 Setting the cutting depth (Figure 4)

•

Release the handle on the rear of the guard

hood for adjusting the cutting depth (4).

•

Place the saw foot (6) flat on the surface of the

workpiece you wish to saw. Raise the saw until

the saw blade (12) is at the required cutting depth

(a).

•

Refasten the handle for adjusting the cutting

depth (4). Check the handle is securely fastened.

7.3 Miter stop (Figure 5)

•

The preset standard angle between the saw foot

(6) and saw blade (12) is 90°. You can adjust this

angle to carry out angled cuts.

•

Release the locking lever for miter setting (7) on

the front of the saw foot.

•

You can now adjust the cutting angle to around

45°. Keep an eye on the cutting angle scale (9) as

you do so.

•

Refasten the locking lever for miter setting (7).

Check the handle is securely fastened.

7.4 Extraction of dust and chips

•

Connect a suitable vacuum cleaner to the

provided chip extractor connector (14) of your

circular saw (vacuum cleaner not included). This

will provide excellent dust extraction on the

workpiece. The benefits are that you will protect

both the equipment and your own health. Your

work area will also be cleaner and safer.

•

Dust created when working may be dangerous.

Refer to the section entitled “Safety instructions”.

•

Important! The vacuum cleaner you use for the

extraction work must be suitable for the

workpiece material.

•

Check that all the parts are properly connected.

7.5 Parallel stop (Figure 6)

•

The parallel stop (16) enables you to saw parallel

lines.