-4-

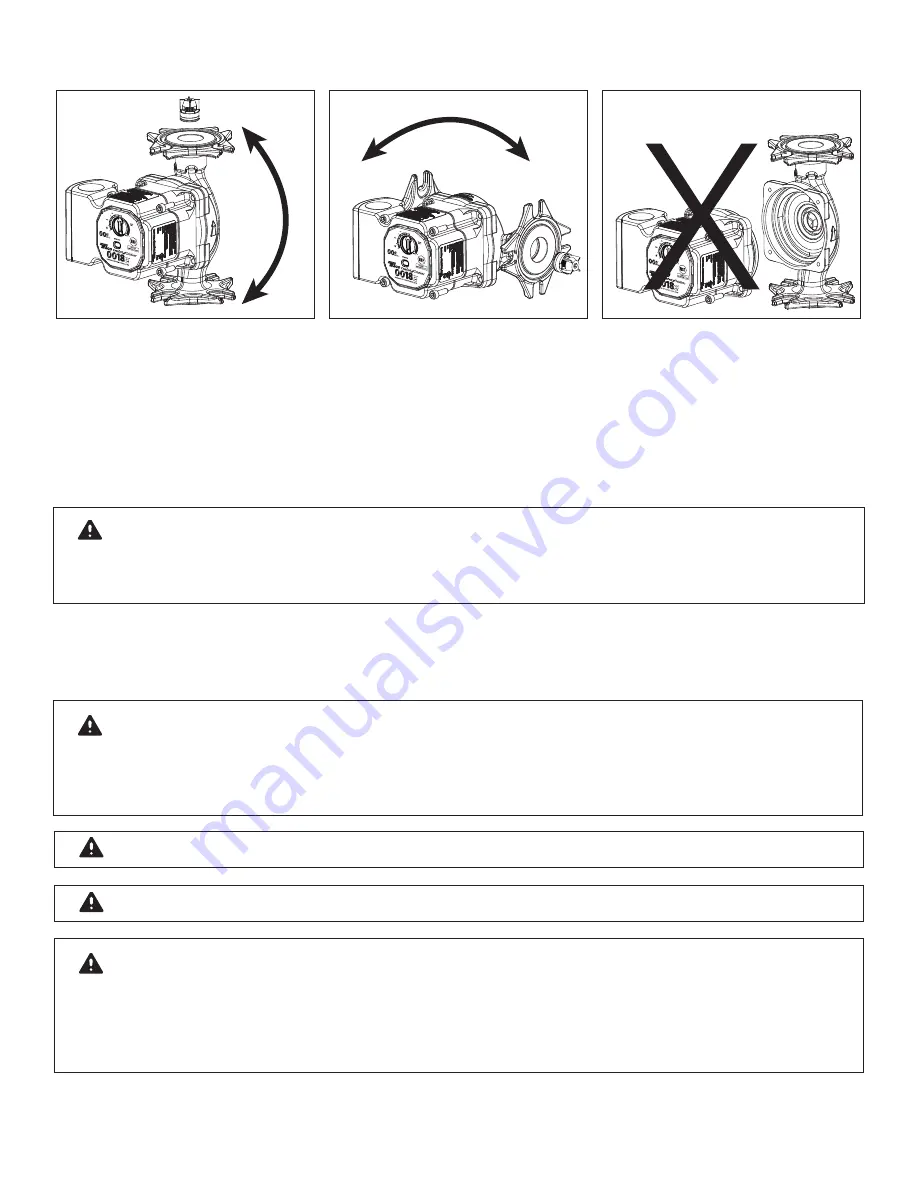

ACCEPTABLE MOTOR MOUNTING POSITIONS AND EASY CASING ROTATION

Figure

Figure

Figure 6:

Do not detach motor

from pump casing. Simply spin

casing to the proper flow direction.

Spin

casing

to

change

flow

direction.

Spin casing

to change

flow direction.

4:

5:

Always install with motor in horizontal

orientation. Position electrical junction box

at 9 o’clock for best viewing orientation.

Pump casing may be rotated to change flow

direction. Locate the arrow on the casing

body to determine flow direction.

To rotate the pump casing, remove the 4 motor screws. When rotating pump casing position,

DO NOT detach motor housing from the casing. Damage to the casing O-ring and leakage may result.

Simply spin casing to the proper flow direction desired as shown in Figure 4 and Figure 5. Reattach

the 4 screws (1⁄8” allens wrench required). Be sure motor is positioned correctly and is seated evenly

to prevent leakage or damage to O-ring. Tighten motor screws evenly to 25-38 in-lbs torque.

Integral Flow Check (IFC®) option

- An IFC® is included in the carton. If required, press IFC into machined discharge port with plunger and

o-ring facing in, until it snaps into place. Before installing, press IFC plunger to be sure it moves freely. See diagram above.

CAUTION:

To reduce the possibility of noise transmission, be sure to add vibration dampeners to piping

when mounting circulator to wall or floor joists.

ATTENTION:

Pour réduire la possibilité de transmission de bruit, veillez à ajouter des amortisseurs de

vibration à la tuyauterie lors du montage du circulateur sur des chevêtres de mur ou de plancher.

5. Filling the system:

The system must be filled before operating the circulator. The bearings are water lubricated and should not be

allowed to operate dry. Filling the system will result in immediate lubrication of the bearings. It is always good practice to flush a new

system of foreign matter before startin the circulator.

WARNING:

Risk of electric shock. To reduce the risk of electric shock, be certain that it is connected only to a properly

grounded, grounding-type receptacle. Follow all local electrical and plumbing codes.

AVERTISSEMENT:

Risque de choc électrique. Pour réduire le risque de choc électrique, veillez à ce qu’elle soit raccordée

uniquement à un réceptacle de type mise à la terre proprement mis à la terre. Respectez tous les codes de plomberie et

électriques locaux.

WARNING:

Use supply wires suitable for 90°C.

AVERTISSEMENT:

Employer des fils d’alimentation adeqauts pour 90°C.

WARNING:

Disconnect power when servicing.

CAUTION:

Use flexible conduit only. Not for use with rigid conduit.

WARNING:

SERVICING OF DOUBLE-INSULATED APPLIANCES. A double-insulated appliance is marked with one or more of the

following: The words “DOUBLE INSULATION” or “DOUBLE INSULATED” or the double insulation symbol (square within a square).

In a double-insulated appliance, two systems of insulation are provided instead of grounding. No grounding means is provided

on a double-insulated appliance, nor should a means for grounding be added. Servicing a double-insulated appliance requires

extreme care and knowledge of the system, and should be done by qualified service personnel. Replacement parts for a dou-

ble-insulated appliance must be identical to the parts they replace.

Summary of Contents for 0018e-SF4

Page 11: ... 11 NOTES ...