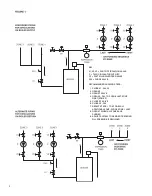

HOT

NEUTRAL

GROUND

BLACK

WHITE

GREEN

SCREW

TERMINAL BOX

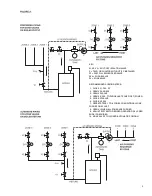

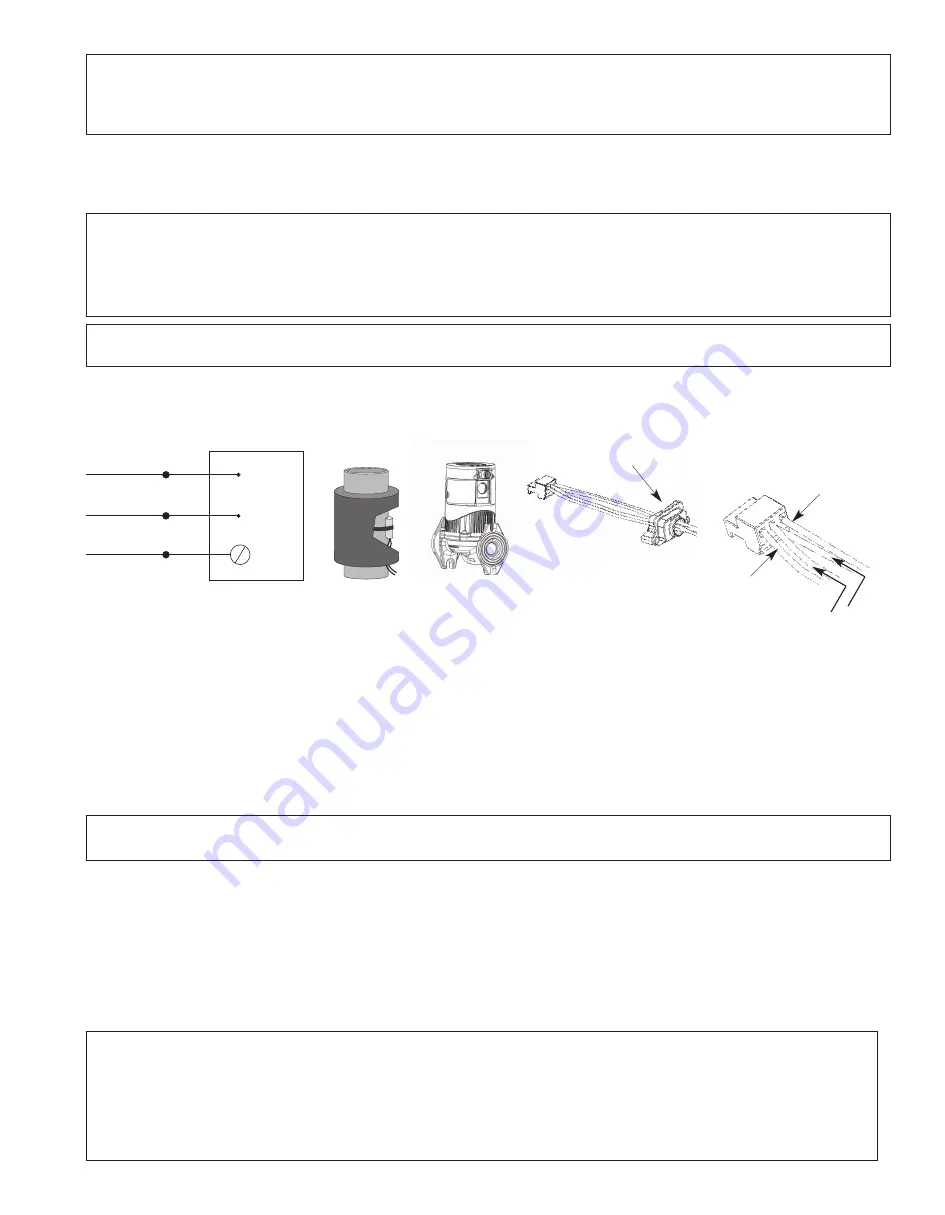

• Disconnect AC power supply. Remove terminal box cover. Thread a wiring connector into npt knockout.

Note:

To install an angle connector

removal of sensor cap may be required for clearance. Connect hot wire to black lead and neutral wire to white lead. Connect ground wire to Green

Ground screw. Replace terminal box cover.

• Remove sensor cap. Slide sensor wires through grommet in sensor cap. See diagram above.

• Attach sensor wires provided as shown:

- Delta-T mode uses supply and return (S + R).

- Set Point mode uses supply (S) for system sensor and return (R) for boiler protection return sensor.

• Attach sensors to supply and return piping using the zip-ties provided. See diagram above.

- In Delta-T mode, place sensors on system supply and return.

- In Set Point Heat mode, place supply sensor on system loop supply. If boiler protection option is used, place return sensor on boiler return.

• Insulate pipe around sensors as shown.

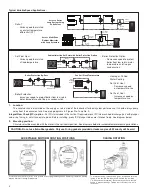

5. Start the circulator:

Note:

When power is applied to the circulator it will go through a 10 second diagnostic delay before starting. The LCD will illu-

minate for the first 5 minutes of a run cycle. Press any of the programming buttons to re-illuminate the LCD.

When air purging the system, it is recommended to run the circulator at full speed long enough to remove all remaining air from the bear-

ing chamber. This is especially important when installing the circulator in the off-season.

Full Speed Over-Ride Feature:

To run the pump at full speed during the fast fill, start-up and purge process, press and hold the

UP

button for 3 seconds until “Full

Speed Override” appears on the LCD display. To return to the programmed, normal operating mode, press the

SET

button.

“SureStart”

Feature:

In rare cases where a locked rotor may occur, the SureStart feature will activate automatically and rapidly vibrate

to unblock the rotor and continue normal operation.

6. Programming your VT2218 circulator:

Note:

The VT2218 is factory-programmed for

Delta-T

operating mode with a

20°F

temperature differential setting. If this is your

desired operating mode and Delta-T setting, no programming changes are required.

CAUTION: Never run the circulator dry or permanent damage may result.

ATTENTION: Ne laissez jamais le circulateur tourner à sec, des dommages permanents peuvent en résulter.

The VT2218 has 5 Operating Modes:

• Delta-T - Varies speed to maintain a fixed temperature differential (factory pre-set mode).

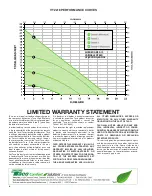

• Constant Speed - 4 fixed speeds (see pump curves on previous page to select desired performance).

• Set Point Heat - Increases speed to increase temperature (includes Boiler Protection option).

• Set Point Cool - Increases speed to lower temperature.

• Boiler Protection - Varies speed to maintain minimum boiler return temperature.

WARNING: Use supply wires suitable for 90°C,

AVERTISSEMENT: Employer des fils d’alimentation adeqauts pour 90°C.

3. Fill the system with tap water or a maximum of 50% propylene-glycol and water solution:

The system must be filled before operating the circulator. The bearings are water lubricated and should not be allowed to operate

dry. Filling the system will result in immediate lubrication of the bearings. It is always good practice to flush a new system of foreign

matter before starting the circulator.

CAUTION: To reduce the possibility of noise transmission, be sure to add vibration dampeners to piping when

mounting circulator to wall or floor joists.

ATTENTION: Pour réduire la possibilité de transmission de bruit, veillez à ajouter des amortisseurs de vibration à la

tuyauterie lors du montage du circulateur sur des chevêtres de mur ou de plancher.

WARNING: Risk of electric shock. To reduce the risk of electric shock, be certain that it is connected only to a prop-

erly grounded, grounding-type receptacle. Follow all local electrical and plumbing codes.

AVERTISSEMENT: Risque de choc électrique. Pour réduire le risque de choc électrique, veillez à ce qu'elle soit rac-

cordée uniquement à un réceptacle de type mise à la terre proprement mis à la terre. Respectez tous les codes de

plomberie et électriques locaux.

4. Wiring the circulator:

Sensor Cap with Grommet

Return Sensor (R)

Supply Sensor (S)

Common

Sensor Cap with Grommet

5