- 11 -

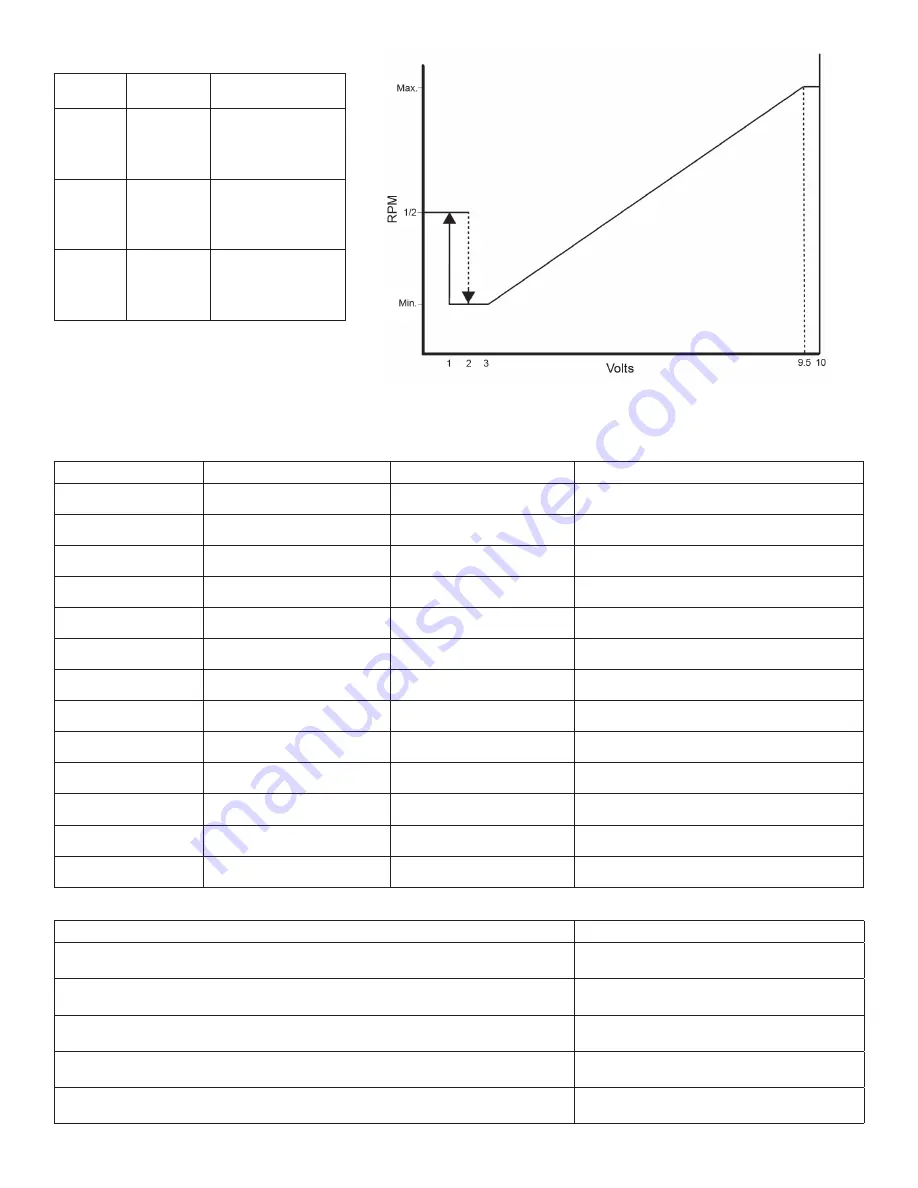

Analog Control Curve

RUN

Voltage

MAX.

Voltage

Function

> 1 V

< 3 V

Pump at

minimum speed.

= 0 V

< 2 V

Pump is at

1/2 speed.

> 3 V

3 to 10 V

Speed is proportional

to voltage regulation.

22 - Fault Finding & Error Codes

The pump Status LED will flash red during errors and overload conditions. The sequence

of the flash is determined by the type of the error per the following tables.

0-10v Analog Control

Number of blinks

Error Description

Probable Cause(s)

Pump Response

1 Blink

Locked Rotor

Motor

Restarts 10 times then shut down/off

2 Blinks

Over Current

Motor

Shut down/off

3 Blinks

Over Temperature

Motor

Shut down/off

Orange Blinking

Temperature Error

Motor

Reduce speed

4 Blinks

Over Voltage

Motor

Shut down/off

5 Blinks

Under Voltage

Motor

Shut down/off

6 Blinks

COMM Fault Error (TX/RX)

UI or Motor

Run at Constant Speed 1

7 Blinks

Safety Routine Error

Motor

Shut down/off

8 Blinks

Staging Fault

UI

Shut down/off

9 Blinks

Dry Run Fault

Motor

Shut down/off

10 Blinks

PFC IAC Error

Motor

Shut down/off

11 Blinks

PFC IAVG Error

Motor

Shut down/off

12 Blinks

BUS Voltage Error

Motor

Shut down/off

Error Codes for 1915ecm •

(Blinks in 1/2 second intervals for a period 15 sec)

23 - Replacement Parts

Replacement Part Description

Part Number

Application Control Circuit Board

9300-4046-PUR-RP

Standard Seal, Carbon/Silicon-Carbide/EPDM*

198-3079RP

NSF Compatible Seal, Carbon/Silicon-Carbide/Viton*

198-3080RP

Impeller Assembly, Standard Seal, Carbon/Silicon-Carbide/EPDM*

198-3249RP

Impeller Assembly, NSF Compatible Seal, Carbon/Silicon-Carbide/Viton*

198-3250RP

* Includes Gaskets (Casing and Flange)