- 3 -

Section 1. Installation and Operation

Warning:

Installation and use of this product requires

experience and knowledge of this or similar products.

Persons with reduced physical, mental or sensory

capabilities must not use this product, unless properly

instructed and supervised. Children must not be allowed

to play with this product.

Avertissement:

l'installation et l'utilisation de ce produit exigent

une expérience et des connaissances de ce produit ou de produits

semblables. Une personne aux capacités physiques, mentales ou

sensorielles réduites ne doit pas utiliser ce produit, à moins d’être

correctement instruite et supervisée. On ne doit pas laisser les

enfants jouer avec ce produit.

Introduction

This manual is broken down into two sections and describes the installation,

operation and control module for 1900e

®

series pumps. Section 1 describes

the installation and operation features. Section 2 describes the control mod-

ule and its functions.

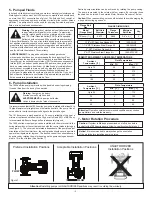

1 - General Information Uses

The 1900e series circulating pumps are available in 2 versions. The ductile

iron version is used for the transfer of liquid media within a closed-loop

hot-water heating or air-conditioning hydronic system. The stainless steel

version is used in potable DHW systems or where NSF/ANSI 61 & 372

compliance is required.

Both the ductile iron and stainless steel versions are designed as single or

parallel main/standby operation variable-speed pumps, where the speed is

regulated by an on-board electronic device.

2 - Safety

These instructions should be studied carefully before installing or operating

the pump. They are meant to help you with installation, use and mainte-

nance and to increase your safety. Installation should be performed with re-

gards to local or national standards. Only qualified personnel should main-

tain and service these products. Failure to comply with safety precautions

could cause personal injury or machinery damage.

Warning:

Do not use in swimming pool or spa areas. Pump

has not been investigated for these applications.

AVERTISSEMENT:

Ne pas utiliser dans une piscine ou un

spa. La pompe n’a pas été étudiée pour ces applications.

Warning:

To avoid electrical shock, disconnect the power

supply to the circulator and the main electrical unit. Follow

all local electrical and plumbing codes.

AVERTISSEMENT:

Pour éviter tout choc électrique,

débranchez l’alimentation électrique vers le circu-lateur et

l’unité électrique principale. Respectez tous les codes de

plomberie et électriques locaux.

Warning:

Hot surfaces can cause burns. The motor can

also reach temperatures that could cause injury.

AVERTISSEMENT:

Les surfaces chaudes peuvent provo-

quer des brûlures. Le moteur peut également atteindre des

températures qui peuvent entraîner des blessures.

Warning:

The addition of petroleum based fluids or certain

chemical additives to systems using TACO equipment voids

the warranty.

AVERTISSEMENT:

L’ajout de liquides à base de pétrole ou

de certains additifs chimiques à des systèmes utilisant un

équipement TACO annule la garantie.

Warning:

Use supply wires suitable for 90°C.

Warning:

Misconnection or overload of electrical or

signal connections could cause pump to shut-down or

cause permanent damage.

AVERTISSEMENT:

Employer des fils d’alimentation

adeqauts pour 90°C.

AVERTISSEMENT:

Toute erreur de raccordement

ou surcharge des connexions électriques ou de

signalisation peut entraîner un arrêt de la pompe

ou des dommages permanents.

Warning:

Do not operate pump without the electrical

cover securely attached.

AVERTISSEMENT:

Ne pas actionner la pompe si le

couvercleélectrique n’est pas correctement fixé.

Warning:

Pump motor, electronics enclosure and conden-

sate drain openings should not be thermally insulated as

it could interfere with cooling and condensate drainage.

AVERTISSEMENT:

Lemoteur depompe, l’enceinte

électronique et les ouvertures de drainage de condensat

doivent être thermiquement isolés car il peut y avoir interférence avec

l’évacuation de condensat et deliquide de refroidissement.

3 - Pump Description

The high efficiency, electronically commutated, close coupled 1900e series

pumps consist of two main parts; the centrifugal pump and the electronic

control. The hydraulic section is sealed from the motor assembly by a me-

chanical seal. 1900e series pumps are powered by an electronically com-

mutated permanent magnet motor (ECM) which does not consume energy

to magnetize the rotor, providing superior energy efficiency.

The ECM motor is run by an on-board frequency converter. The converter

estimates current flow and head from the motor load and speed. With this

information the self-sensing ECM pump constantly calculates pump head

and flow and adapts motor speed to the appropriate flow for the selected

curve.

3.1 - Features

• 10 easy to set modes to match system requirements.

º

4 - Constant Pressure modes.

º

3 - Constant Speed modes.

º

1 - Proportional Pressure mode.

º

1 - 0-10v mode.

º

1 - 2-pump operation mode.

• ECM performance equivalent to the versatile 1900 & 1600 series

pumps.

• Fully rotational User Interface (UI) to accommodate any pump position.

• Led Status monitors Pump On (solid green), Pump in Standby (flashing

green) and Error (flashing red error code - see section 22.1)

• Mechanically sealed for easy maintenance.

4 - Use

All 1900e series pumps equipped with a ductile iron casing are intended

for circulation of solid-free fluid in pressurized, hot and chilled hydronic sys-

tems. All 1900e series pumps equipped with a stainless steel casing are

intended for DHW and potable water applications and are NSF Commercial

Hot (180°F water) rated and suitable for sanitizing applications.