- 6 -

12 - Setup and Operation

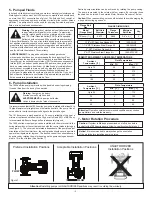

12.1 - Control (UI) Panel Layout

0-10V

Lead/2-Pump Operation

Proportional Pressure

Status

SELECT

MODE

SET

MODE

2-PUMP

OPERATION

HOLD BOTH 3s

000-0000

1915

ecm

HIGH-EFFICIENCY CIRCULATOR

TM

25

35

45

65

HEAD FEE

T

HEAD FEE

T

FLOW GPM — Constant Pressure

120

15

25

35

FLOW GPM — Constant Speed

80 100 120

MODES

1

2

3

4

5

6

7

8

1. Status LED

2. Constant Pressure Mode Setting LED

3. Constant Speed Mode Setting LED

4. Proportional Pressure Mode LED

5. 0-10v Mode LED

6. 2-Pump Operation LED

7. [^] Select Mode Button

8. [O] Set Mode Button

12.2 - Switching the Pump On and Off

When the pump is powered for the first time, it operates with the factory

default setting in Constant Pressure mode equal to 33ft of head.

The pump requires dry contact to run and comes with a jumper across the

ENABLE INPUT (J4) contacts found on the Control Panel UI. The pump

will run when connected to a power source when the jumper is connected.

Turning the pump on/off remotely is accomplished by accessing the

ENABLE INPUT (J4) contacts on the UI control board located under the

UI and connecting the contacts to an external relay. Access is gained by

removing the 4 screws located in each of the UI panel’s four corners.

Note: After powering up, wait 5 minutes before powering off.

13 - Pump Functions

[^] Select Mode Button

Short press:

Change Mode

• Scrolling through operational modes upwards. Current operation-

al mode LED blinking. To accept the new mode press the Set

Mode button.

Long Press (10 seconds) –

LOCKOUT

• Pressing and holding the [O] Set Mode Button for 10 seconds

activates or deactivates pump LOCKOUT. In LOCKOUT, the cur-

rently selected mode is active only. No changes can be made

while in LOCKOUT. LOCKOUT activation or deactivation is ac-

knowledged by all LED’s blinking on and off once, and returns to

display current operating mode.

[^] Select Mode [O] Set Mode Button

Long press (3 seconds):

2-Pump Operation

• To select or deselect 2-pump (lead/lag) operation.

13.1 - Pump Modes, 0-10Vdc and Parallel Pump Operation

The pump can operate in 9 different modes. Set the pump in the most

appropriate mode depending on the system where the pump operates.

The pump modes are:

Constant Pressure:

4 settings

65ft, 45ft, 35ft, 25ft (Changes impeller speed to maintain pressure

as flow increases)

• The pump maintains the selected pressure from 0 flow to

maximum power. At maximum power the pressure begins

to drop with increasing flow.

Constant Speed:

3

settings

35ft, 25ft, 15ft (Maintains speed at selected head at 0 flow)

• In Constant Speed mode the impeller speed is maintained

through the entire range of flow.

Automatic Mode:

1 setting (Proportional Pressure - increases impeller

speed to increase differential head as flow increases)

• In automatic mode the pump sets the operating pressure depending

on the system resistance.

• The parameters are preset and cannot be changed.

0 – 10Vdc:

• In this mode, all automatic curves are deactivated for full control via

an external signal. A dry contact from the external source is used to

activate or deactivate the pump. Pump speed is controlled via a 0-10V

DC signal. Loss of the 0-10V DC signal defaults pump to 50% of full

speed. The 0-10Vdc output signal is a linear relationship between speed

and Vdc regardless of the selected mode. 1-3 Vdc is minimum speed,

10 Vdc is maximum speed, 6.5 Vdc is medium speed etc.

• 0-10Vdc operation is unavailable in 2 pump mode.

To switch between modes (except 2-Pump Operation) depress the

[^] Select Mode

button for 1 second. The selected mode LED will begin

blinking. Continue pressing the

[^] Select Mode

button to scroll through

the available modes indicated by the mode’s blinking LED. Press the

[O] Set Mode

button to accept the desired operating mode.

2-Pump Operation:

1 setting

• This option is selected when 2-pump alternation is desired.

• Pumps will alternate run-time every 24 hours (not adjustable).

• In this mode the lead pump will control the operation of the lag pump.

1. Set both pumps to the same Mode

2. Turn main power off to both pumps

3. Connect Primary Pump “P1” relay output common and NC to

“P2” Enable Input (see 21.1 - Connection Examples Parallel

Pump Operation). NOTE: Remove factory installed jumper

from “P2” Enable Input

4. Connect “P2” 0 – 10Vdc Output to “P1” 0-10Vdc Input, positive

to positive and negative to negative

5. NOTE: Between pumps standard 18ga unshielded

communication wire is sufficient

To activate or deactivate 2-Pump Operation, press the

[^] Select Mode

button

+ [O] Set Mode

button together and hold for 3 seconds. The

2-Pump Operation LED will light indicating 2-Pump Operation activation.

The LED will go out upon deactivation. Only the master pump should be

set to 2-pump operation.

Once in 2-Pump operation, press the SELECT MODE button and the

SEST MODE button together for 1 second to switch the running pump.

f. Connect the black wire of the pump

to the “Hot/ Live” wire of the

system. Typically black, or red

wire if no black wire is present.

When no black wire is present,

a red wire is a secondary live

wire found in some 220/1

circuits.

Connect the white wire of the

pump to the white or gray

neutral wire of the system.

The green ground wire is

connected to the grounding

terminal inside the pump.

See figure 2 noted to the left.

Figure 2

1915ecm

Electrical opening: 1/2”

14 MPSM standard thread

[O] Set Mode Button

Short press:

Confirm Selection

• To confirm the mode currently selected.

Selected operational mode LED solid.

NOTE:

Pump returns to previous operational mode

if Set Mode is not pressed.