13

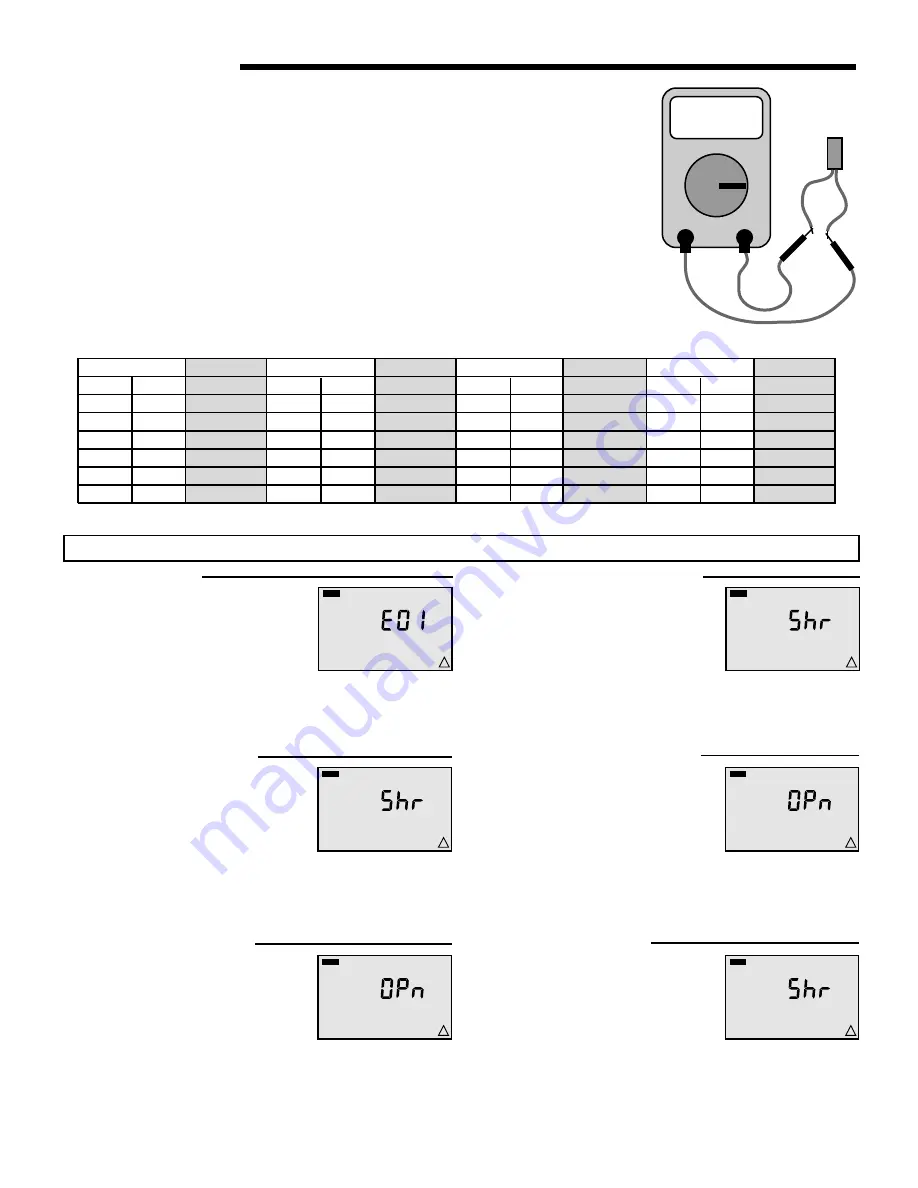

TESTING THE SENSORS

Do not apply voltage to the sensor or to the sensor input of the control as this will result in damage

to either the sensor, the control, or both the sensor and the control.

A quality testing meter capable of measuring up to 2,000,000 ohms and a good quality digital

thermometer are required to test the sensors. If a digital thermometer is not available, place a

second sensor next to the original sensor and compare the readings.

Begin by measuring the temperature at the sensor location using the digital thermometer. Next,

measure the resistance of the sensor using the testing meter. Ensure that the sensor is discon-

nect from the control at the time of testing. Using the reference chart below, determine the sensor’s

temperature. Compare the sensor’s temperature to that measured by the digital thermometer. The

two temperature readings should be close.

If the sensors temperature is too high, this can indicate that there is a partial short in the sensor

wiring. If the sensor’s temperature is too low, this can indicate that there is a loose connection or

break in the sensor wiring. Isolate and repair the problem. If the problem is isolated to the sensor,

replace the sensor.

-30

-20

-10

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

-34

-29

-23

-18

-12

-7

-1

4

10

16

21

27

32

38

43

49

54

60

66

71

77

82

88

93

234,000

165,000

118,000

85,500

62,500

46,000

34,500

26,000

20,000

15,500

12,000

9,300

7,300

5,800

4,700

3,800

3,100

2,500

2,000

1,700

1,400

1,200

1,000

800

Temperature Resistance

F

C

Ohms

Temperature Resistance

F

C

Ohms

Temperature Resistance

F

C

Ohms

Temperature Resistance

F

C

Ohms

EEPROM Read Error

The control was unable to read the in-

stallers settings from its memory. The

control was forced to load the factory

defaults for all settings. The control will

stop operation until all of the settings

in the Adjust menu have been checked.

O

Error Messages

VIEW

!

MIX

VIEW

!

RET

Mixing Return Sensor Short Circuit

A short circuit has been detected in the

mixing return sensor. If the Maximum

Delta T setting is set to OFF, the con-

trol continues operation. If the Maxi-

mum Delta T setting is not set to OFF,

the control stops operation until the

fault is corrected. To clear this error

message, correct the short circuit and

press any button on the control.

M

Outdoor Sensor Short Circuit

A short circuit has been detected in the

outdoor sensor. The control assumes

an outdoor temperature of 32

°

F (0

°

C)

and continues operation. To clear this

error message, correct the short circuit

and press any button on the control.

OUT

VIEW

!

MIX

VIEW

!

RET

Mixing Return Sensor Open Circuit

An open circuit has been detected in

the mixing return sensor. If the Maxi-

mum Delta T setting is set to OFF, the

control continues operation. If the Maxi-

mum Delta T setting is not set to OFF,

the control stops operation until the

fault is corrected. To clear this error

message, correct the open circuit and

press any button on the control.

B

Outdoor Sensor Open Circuit

An open circuit has been detected in

the outdoor sensor. The control as-

sumes an outdoor temperature of 32

°

F

(0

°

C) and continues operation. To clear

this error message, correct the open

circuit and press any button on the con-

trol.

OUT

VIEW

!

VIEW

!

BOIL

Boiler Sensor Short Circuit

A short circuit has been detected in the

boiler sensor. The boiler contact is

operated as if a boiler sensor is not

installed. The control provides a boiler

enable and does not provide boiler pro-

tection. To clear this error message,

correct the short circuit and press any

button on the control.

Summary of Contents for Radiant Mixing Block

Page 2: ...2 Typical Piping ...