16

008 MOTOR

CONNECTION FROM

CONNECTION FROM

LINE (BLACK)

006 MOTOR

CONNECTION FROM

QUICK DISCONNECT

CONNECTION FROM

NEUTRAL ( WHITE)

INSTALL ADDITIONAL

IMC

LINE & NEUTRAL

IF C

A

CONNECTIONS

GROUND SCREW

COVE R

IMC

ASSEMBLY

CASING

BACK COVER

AIR VENT

GROUND

CONNECTION

BODY BOLTS (8)

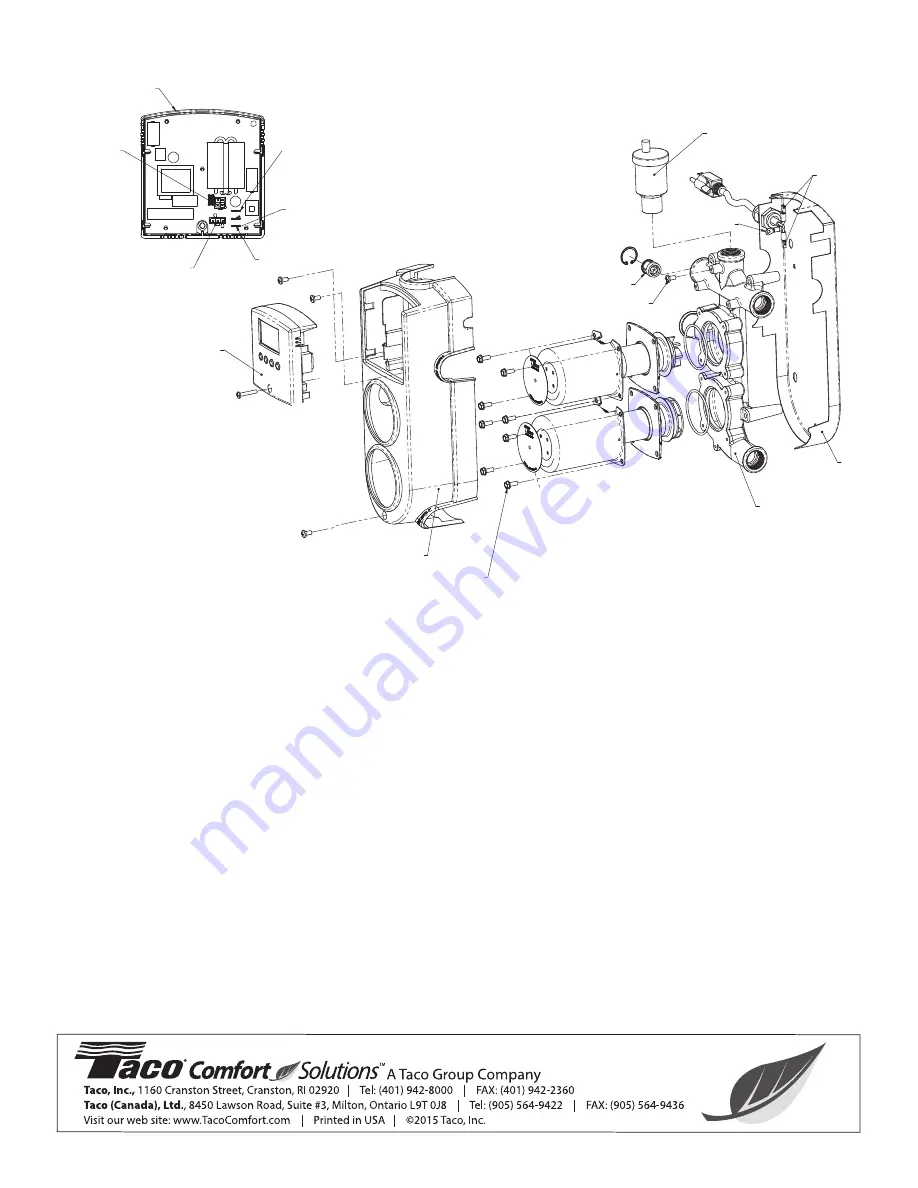

1. Control Board

2. Outdoor Sensor

3. Strap-On Sensor

4. Top Injection Pump Cartridge

5. Bottom System Pump Cartridge

6. Top Injection Pump Motor Only

Replacement Parts Breakdown

LIMITED WARRANTY STATEMENT

Taco, Inc. will repair or replace without charge (at the

company’s option) any product or part which is proven

defective under normal use within one (1) year from the

date of startup or one (1) year and six (6) months from

the date of shipment (whichever occurs first). Taco, Inc.

will repair or replace without charge (at the company’s

option) any Taco 00 Series circulator cartridge that is

proven defective under normal use within three (3) years

from the date of manufacture.

In order to obtain service under this warranty, it is the re-

sponsibility of the purchaser to promptly notify the local

Taco stocking distributor or Taco in writing and promptly

deliver the subject product or part, delivery prepaid, to the

stocking distributor. For assistance on warranty returns,

the purchaser may either contact the local Taco stocking

distributor or Taco. If the subject product or part contains

no defect as covered in this warranty, the purchaser will

be billed for parts and labor charges in effect at time of

factory examination and repair.

Any Taco product or part not installed or operated in con-

formity with Taco instructions or which has been subject

to misuse, misapplication, the addition of petroleum-

based fluids or certain chemical additives to the systems,

or other abuse, will not be covered by this warranty.

If in doubt as to whether a particular substance is suitable

for use with a Taco product or part, or for any application

restrictions, consult the applicable Taco instruction

sheets or contact Taco at (401-942-8000).

Taco reserves the right to provide replacement products

and parts which are substantially similar in design and

functionally equivalent to the defective product or part.

Taco reserves the right to make changes in details of de-

sign, construction, or arrangement of materials of its

products without notification.

TACO OFFERS THIS WARRANTY IN LIEU OF ALL

OTHER EXPRESS WARRANTIES. ANY WARRANTY

IMPLIED BY LAW INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS IS IN EFFECT ONLY

FOR THE DURATION OF THE EXPRESS WARRANTY

SET FORTH IN THE FIRST PARAGRAPH ABOVE.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR STATUTORY,

OR ANY OTHER WARRANTY OBLIGATION ON THE

PART OF TACO.

TACO WILL NOT BE LIABLE FOR ANY SPECIAL, INCI-

DENTAL, INDIRECT OR CONSEQUENTIAL DAMAGES

RESULTING FROM THE USE OF ITS PRODUCTS OR

ANY INCIDENTAL COSTS OF REMOVING OR RE-

PLACING DEFECTIVE PRODUCTS.

This warranty gives the purchaser specific rights, and the

purchaser may have other rights which vary from state

to state. Some states do not allow limitations on how long

an implied warranty lasts or on the exclusion of incidental

or consequential damages, so these limitations or exclu-

sions may not apply to you.

1.

11.

9.

10.

or

6.

7.

4.

5.

8.

193-004RP

9300-2052RP

9300-2044RP

005-020RP

008-045RP

193-015RP

7. Bottom System Pump Motor

8. Only Air Vent

9. Check Valve Dated 6/05 or Older

10. Check Valve Dated 7/05 or Newer

11. Brown Button Fuse

193-016RP

419-1

193-003RP

193-030RP

26-784RP

Replacement Parts

Summary of Contents for Radiant Mixing Block

Page 2: ...2 Typical Piping ...