Gallant User Manual

| 57

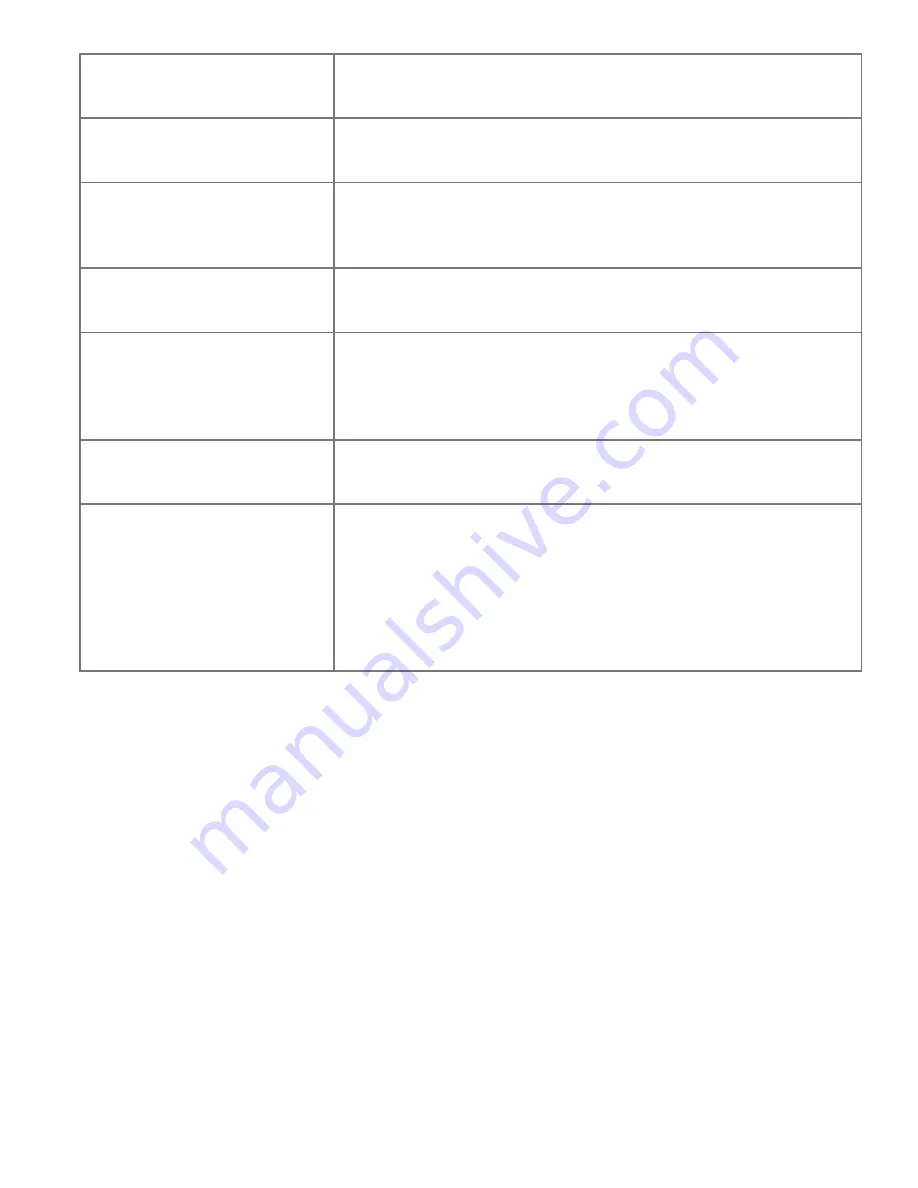

Needle is burred, bent or dull, or

installed incorrectly

• Change the needle at least once per quilt. Make sure the needle is

installed to the top of the sight hole in the needle bar.

Needle not suitable for thread

•

Replace the needle to one better suited for the thread. Use the

proper size needle. Refer to chart in Machine Needle section.

Hesitating too long at one point

in quilting motif

•

Move more quickly so stitches don’t overlap or build up. When

starting the machine, begin moving immediately. Sewing in one

place too long will cause the thread to break.

Improper needle/hook

relationship

•

Machine timing needs to be checked. Consult an authorized

Baby Lock technician.

Damage or burr at needle hole

of throat plate or other thread

handling part

• If thread is shredding at the throat plate, check for burrs or jagged

edges. Gently rub with emery cloth to remove the sharp edge.

Consult a repair technician to polish any hard-to-reach or delicate

areas.

Wrong type of needle

• Use only the needles recommended by Baby Lock

(needle system 134, sizes 12 through 21).

Other possible problems

•

Needle too close to hook, causing friction and possible collision

of hook point and needle (causing broken thread).

• Needle plate damage

• Hook damage

• Broken needles or damaged needle bar clamp

NO

TE: If the troubleshooting tips do not eliminate the problem, please consult an

authorized Baby Lock retailer.