The area to be scrubbed:

Debris and grit must be swept up

before starting the scrubbing operation to avoid vacuum line

blockage and to permit the detergent to perform efficiently.

Starting up and operation:

Disconnect the batteries from the

battery charger and connect to the machine. Then:

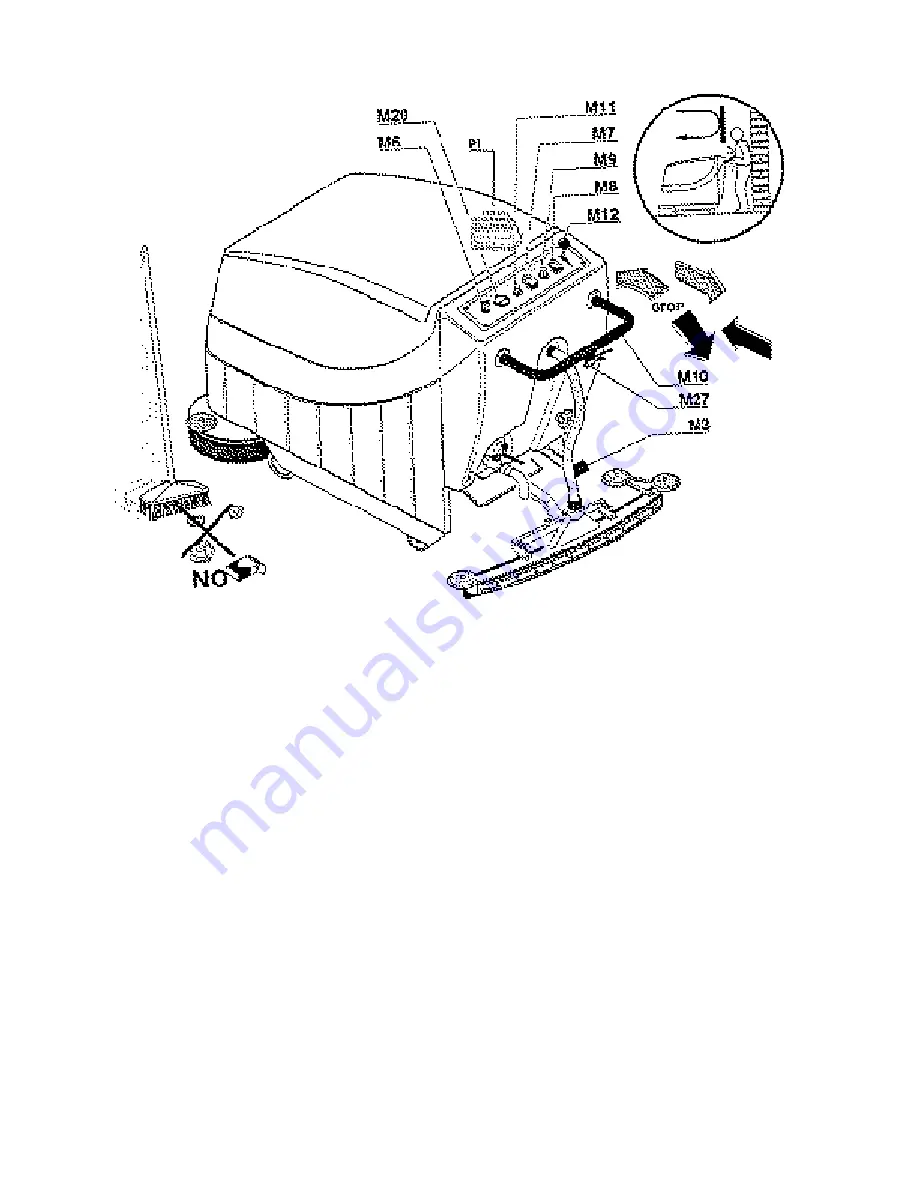

• Turn master switch

M6

to position 1 and press

switches

M7

and

M8.

• Lower the brushes by turning knob

M9

clockwise.

Maximum setting is #10. Only use the pressure setting

that effectively performs the cleaning desired for the

longest run time and fastest operation.

• Lower the squeegee by pressing pedal

M3.

• Set the detergent solution supply to minimum by raising

the adjusting knob

M12

.

• Release the brake by squeezing the small lever.

• Press down the handle

M10

to drive forward.

When the handle is released the machine stops.

• Adjust the speed of advance by adjusting knob

M11.

• Finally, adjust the correct supply of the detergent in

relation to the amount of dirt and speed of advance by

means of lever

M12

; this is a matter of experience.

At this point the machine is ready to carry out the operations of

scrubbing and drying at the same time. Single vacuum motor

operation may be all that is necessary for daily scrubbing. To

operate one vacuum open and lock the autoscrubber lid.

Locate the fuse panel P1 attached to the back frame behind the

vacuum motors. Pull and open the first fuse door from the left

side of the fuse housing bank.

CAUTION: Make sure key switch is in the “OFF” position

before installing pad.

Particularly dirty floors:

Certain floors or areas may

require special attention and, in some cases, cleaning twice.

Go over the floor quickly the first time, with the squeegee

raised and the brush in the working position. In this way,

the detergent solution is left on the floor for a longer time

and can dissolve the heavy dirt. The second time, go over

the floor more slowly with both the brush and the squeegee

l o w e r e d .

CAUTION: A)

Loose objects on the floor can become danger-

o u s projectiles if struck by the high-speed pad. Remove them

before o p e r a t i n g this machine.

B )

Keep machine moving to

prevent damage to finish or floor.

C )

These machines are

designed for level floor operations only.

DO NOT OPERAT E

ON RAMPS OR INCLINES greater than 2% grade

unless adequate personnel are available for assistance.

- 5 -