6

7

FASTENING TOOLS

FOR THE PROFESSIONAL

•

Never point any power tool at yourself or at any other

person.

While working, hold the tool in such a way that no

injuries can be caused to the head or to the body in the event of

possible recoil.

•

Do not drive fasteners on top of other fasteners.

•

Do not use this tool to fasten electric cables.

This tool is not

designed for the installation of electric cabling and may damage

electric cables which could lead to injury by electric shock or

fire hazards.

Features

(Fig. A)

1. Trigger

2. Quick Release Plug (Euro Fitting)

3. Magazine Release Latch

4. Magazine

5. Air Deflector

Set up

Your air tool is fully assembled when you receive it. Before using it,

attach the air line and desired air system accessories. See Fig. B for

the recommended accessories and connection order. Be sure the

air hose is de-pressurised when installing or removing adaptors to

the air line.

Connecting The Tool to an Air Supply

(Fig. B)

• Determine if the tool needs oil and, if necessary, place two

drops of oil in the air plug as shown in Fig. B. If you are using an

automatic in-line oiler, check and add oil if necessary.

• Turn the compressor on and set the regulator to the proper

pressure for the size and type of fastener being used.

• Connect the tool to the air supply.

Loading the Tool with Nails

(Fig. C)

• Depress latch (1) situated at the back of the magazine.

• Pull the moveable magazine out.

• Place a strip of fasteners along channel, positioning fasteners at

the bottom of the open magazine channel (2).

• Slide the magazine shut until the magazine release latch clicks.

Operating the Tool

• Connect the tool to the air supply. Make sure the air pressure is

in correct range denoted in section of TECHNICAL DATA.

• Load fasteners as directed in the section called LOADING THE

FASTENERS.

• Hold the body and press the drive guide to work surface, be sure

the tool is straight and then gently depress the trigger to drive

the fastener.

• Lift the tool off the work surface.

Firing Mode

Contact trip (Bump fire):

• First, depress the TRIGGER, then, repeatedly impact the safety

bracket, the tool can repeatedly drive the fasteners.

The tool will drive one fastener when the safety bracket is

impacted once.

NOTE:

The air deflector (Fig.D) is directional and can be rotated

through 360°.

Removing a Jammed Fastener

NOTE:

You must remove any jammed fasteners before using the tool

any further. If you continue to try and fire a fastener while the tool is

jammed, you could cause damage to the mechanism.

• Disconnect tool from the compressed air system

• Remove any unused fasteners from the magazine, this should clear

the jammed fastener(s).

• If any fasteners remain stuck in the nose piece, place tool upside

down on a solid surface. Put a punch or small screwdriver into the

firing nozzle and carefully tap to release the jammed fastener.

•

Close the nose plate and lock the latch before reconnecting to the

air system.

• Following the removal of a jammed fastener, always carefully test

the tool function before proceeding with any work. If fasteners

become jammed in the nose piece frequently, have the tool serviced

by a Tacwise Engineer or appointed service agent.

Regular Maintenance

• Frequent, but not excessive, lubrication is required for best

performance. Oil added through the airline connection will lubricate

internal parts. An automatic airline oiler is recommended but oil

may be added manually before every operation or after about

1 hour of continuous use. Only a few drops of oil at a time are

necessary. Too much oil will collect inside the tool and be blown

out during the exhaust cycle. ONLY USE PNEUMATIC TOOL OIL. Do

not use detergent oil or additives, as these lubricants will cause

accelerated wear to the seal in the tool.

• Use a small amount of oil on all moving surface and pivots.

• Dirt and water in the air supply are major causes of pneumatic

tool wear. Use a filter/oiler for better performance and longer

life. The filter must have adequate flow capacity for the specific

application. Consult the manufacturer’s instructions for proper

maintenance of your filter.

• Keep tools clean for better and safer performance. Use

non-flammable cleaning solutions (CAUTION: Such solutions may

damage O-ring and other tool parts) only if necessary - DO NOT

SOAK.

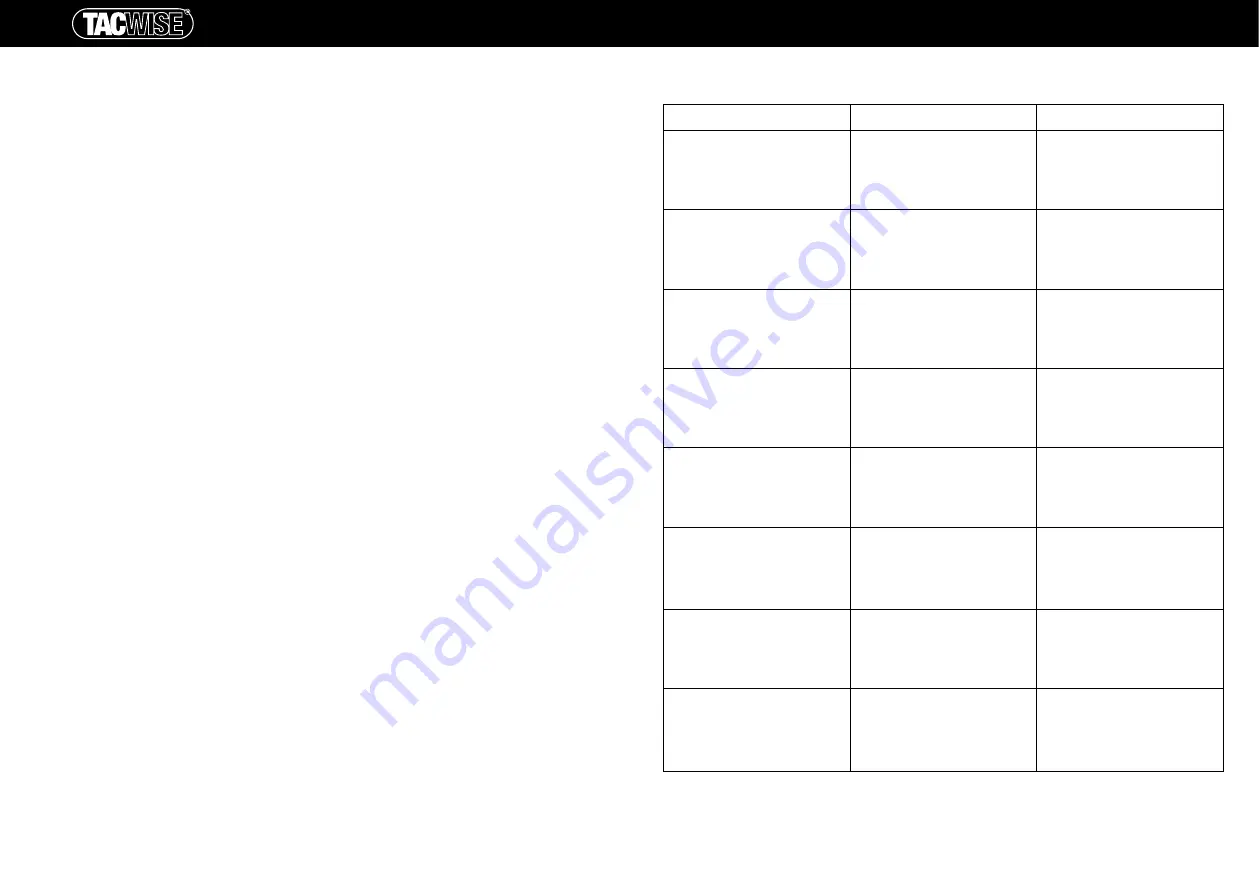

PROBLEM

CAUSE OF PROBLEM

SOLUTION

Air leaking at trigger area

1. O-ring in trigger valve is damaged.

2. Trigger valve head is damaged.

3. Trigger valve stem, seal or O-ring

is damaged.

1. Check and replace O-ring.

2. Check and replace trigger valve head.

3. Check and replace trigger valve stem,

seal or O-ring.

Air leaking between body and front plate

Damaged piston O-ring or bumper

Check and replace O-ring or bumper

Air leaking between body and cylinder cap

1. Screw loose.

2. Damaged seal.

1. Tighten screws.

2. Check and replace seal.

Blade driving fastener too deeply

1. Worn bumper.

2. Air pressure is too high.

1. Replace bumper.

2. Adjust the air pressure.

Runs slowly or has power loss

1. Insufficient oil.

2. Insufficient air supply.

3. Broken spring in cylinder cap.

4. Exhaust port in cylinder cap is blocked.

1. Lubricate as instructed.

2. Check air supply.

3. Replace spring.

4. Replace damaged internal parts.

Tool skips a fastener

1. Worn bumper or damaged spring (53).

2. Dirt in front plate.

3. Inadequate airflow to tool.

4. Worn or dry O-ring on piston.

5. Damaged O-ring on trigger valve.

6. Cylinder cap seal leaking.

1. Replace bumper or pusher spring.

2. Clean drive channel of front plate.

3. Check hose and compressor fittings.

4. Replace O-ring or lubricate.

5. Replace O-ring.

6. Replace seal.

Fasteners are jammed

1. Joint guider is worn.

2. Fasteners are wrong size or damaged.

3. Magazine or front plate screws are loose.

4. Blade in piston assembly is damaged.

1. Replace joint guider.

2. Use the recommended and undamaged

fasteners.

3. Tighten screws.

4. Replace piston assembly.

Tool will not drive down tight

1. Worn blade in piston assembly.

2. Lack of power.

3. Slow cycling and loss of power.

1. Replace piston assembly.

2. Adjust to adequate air pressure.

3. Check cylinder cap spring for broken

coils or reduced length. Check if exhaust

port of cylinder cap is restricted.

Trouble Shooting

Stop using the tool immediately if any of the following problems occur. Serious personal injury could occur. Any repairs or replacements must be

completed by a qualified person or an authorised service centre only.