S - 2 .

S - 2 .

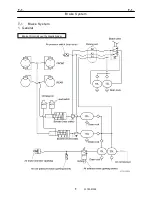

Priority Valve

3

W126-0051E

3. Principle of operation

3.1 Neutral state

While the engine is standing still, spool 2 in the

priority valve is pushed to the left end by spring 3,

fully opening port CF and fully closing port EF.

When the engine is started, the hydraulic oil

delivered from the hydraulic pump flows through

port P and port CF of the priority valve to port P of

the Orbitrol. As the hydraulic pressure in circuit CF

rises in this way, pressure P5 in pressure

chamber A of the priority valve also rises. At this

time, pressure chamber B is connected to the tank

line via port LS and port T of the Orbitrol, and

when the pressure difference (P5 – P6) between

chamber A and chamber B rises to overcome the

force of spring 3, the spool moves towards right

until port EF becomes almost fully opened, and

port CF becomes slightly open. The spool remains

stable in this position, and the pump delivery oil

mostly flows through port EF.

3.2 Right steering

When the steering wheel is turned clockwise, the

hydraulic oil routes inside the Orbitrol are

switched over, causing the oil entering through

port P of the Orbitrol to flow through orifice C1.

Then, the pressures across orifice C1 are

transferred to pressure chambers A and B. The

spool is moved until the pressure difference (P5 –

P6) becomes balanced by spring 3.

3.3 Right steering to the end

When the steering cylinder piston is moved to the

stroke end, the relief valve in the priority valve

actuates, producing oil flow through orifice C2 in

line LS of the priority valve. The pressure

difference across C2 is transferred to pressure

chambers A and B and the spool is further moved

towards right until it becomes stable with port CF

slightly open, and route EF almost fully open.

△

1

366-103-80000

NEUTRAL

RIGHT STEERING

The above figure is for illustrating the principle. The construction of the actual machine may differ from the figure.

Summary of Contents for TR-800XXL4

Page 47: ...B 9 B 9 Rotary Joint 27 W181 0440E Upper view A Lower view B...

Page 119: ...F 1 F 1 Winch System 1 WF02 0251E F 1 Winch System 1 General Hydraulic Circuit for Winch...

Page 135: ...G 1 G 1 Telescoping System 3 WG02 0321E Telescoping cylinder at select...

Page 143: ...G 2 G 2 Boom Five Section Boom G 2 11 W536 0761E 11...

Page 196: ...13 13 W701 0220E K 2 K 2 Air Conditioner K 2 4 Layout 4 1 Overall layout 4 345 107 61000...

Page 197: ...14 14 W701 0220E K 2 K 2 Air Conditioner K 2 4 2 Overall layout 0 345 110 73000...

Page 198: ...15 15 W701 0220E K 2 K 2 Air Conditioner K 2 4 3 Evaporator section 5 345 107 02000...

Page 199: ...16 W701 0220E K 2 K 2 Air Conditioner 5 Compressor Assy...

Page 200: ...17 17 W701 0220E K 2 K 2 Air Conditioner K 2 6 Evaporator Assy...

Page 201: ...18 18 W701 0220E K 2 K 2 Air Conditioner K 2 7 Condenser Assy...

Page 202: ...19 19 W701 0220E K 2 K 2 Air Conditioner K 2 8 Electric 8 1 Electric circuit 0 363 205 60030...

Page 203: ...20 20 W701 0220E K 2 K 2 Air Conditioner K 2 8 2 Main harness A...

Page 204: ...21 21 W701 0220E K 2 K 2 Air Conditioner K 2 8 3 Main harness B...

Page 222: ...39 K 2 K 2 K 2 Air Conditioner 39 W701 0220E 12 2Compressor diagnosis chart 1 2...

Page 223: ...40 K 2 K 2 K 2 Air Conditioner 40 W701 0220E Compressor diagnosis chart 2 2...

Page 224: ...K 2 K 2 Air Conditioner 41 W701 0220E 13 Troubleshooting...

Page 225: ...K 2 K 2 Air Conditioner 42 W701 0220E...

Page 226: ...K 2 K 2 Air Conditioner 43 W701 0220E...

Page 227: ...K 2 K 2 Air Conditioner 44 W701 0220E...

Page 228: ...K 2 K 2 Air Conditioner 45 W701 0220E...

Page 229: ...K 2 K 2 Air Conditioner 46 W701 0220E...

Page 237: ...L 1 L 1 Control System 2 WL02 0090E 2 General of pneumatic control devices Pneumatic Circuit...

Page 291: ...T 5 T 5 Air Dryer 26 W232 0032E Heater View A 39 C B B A 58 59 2 IW232 0030E03...

Page 370: ...8 8 WZ03 3300E Z 5 Z 5 Electric Circuit MDT Carrier Upper Z 5 IWZ03 3300E01...

Page 372: ...10 Z 6 Z 6 Electric Circuit MDT Carrier Lower Z 6 10 WZ03 3310E IWZ03 3310E01...

Page 400: ...38 Z 24 Z 24 Harness Lower Sub 38 WZ04 2450E Z 24 Z 24 Harness Lower Sub 2 349 310 00200...