4

missprints and technical changes reserved

Instruction & Operating Manual

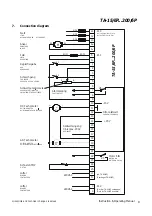

TA-15/6P...200/6P

3.

Drive control adjustments

Phase ballance

P1

Adjustments of the triggering angeles of the individual Thyristors in order to

obtain equal currents for all Thyristors.

Do not adjust.

(This potentiometer is adjusted and sealed by the manufacturer)

Acceleration rate

P2

Adjustment of the linear acceleration time of the motor from min. to max.

speed (2-15 sec.)

IxR Compensation P3

This potentiometer enables to compensate for the voltage drop in the

armature and in the supply line when armature feedback is utilized.

When tachometer feedback is used set this potentiometer fully counter

clockwise.

Deceleration

P4

Adjustment of the linear deceleration time of the motor (provided: positive

torque) from max. to min. speed (adjustable from 2-15 sec.) This

potentiometer is only operative when jumper

VI

is installed or when the

reference speed is changed.

Current limit

P5

Adjustment of the requested max. armature current.

(adjust the nominal motor current)

Minimum Speed

P6

Adjustment of min. speed during operation.

(set potentiometer fully counter clockwise)

Jog speed

P7

Speed adjustment for jog speed

Stability

P8

Adjustment for the dynamical adaption to the load.

Maximum speed

P9

Adjustment of max. speed during operation.

(set potentiometer fully counter clockwise)

Delay time

P10

Adjustment of the control relay from approx. 2-10sec.

(other delay times on request)

4.

Indicators

LED 1

clear

Thyristor triggering

LED 2

green

Power supply -15V

LED 3

red

Indication of malfunction of field, Blocking protection, Phase control, current

output control

LED 4

red

Triggering pulse fault, Current output control

LED 5

green

Power 15V

LED 6

red

Current limit/Over-speed

LED 7

yellow

Jog speed, relay d2

LED 8

green

Line voltage

LED 9

green

D.C supply ON, drive release

LED 10

yellow

Speed control indication (from 10 to 100%), operative only if jumper

VI

is

installed.

LED 11

yellow

Operation, relay d1