TA-U1...U280

Instruction and Operating Manual

Misprints and technical changes reserved

33

4.0 Setting up

4.1 Setting up instructions

Follow the safety advises in Chapter 1. Furthermore the following advice for installation have to be applied.

The installation should only be done by qualified personnel.

Interchanging of the terminals U, V, W while connecting synchronous motor results in a malfunction of the motor.

Furthermore, the encoder cable from the motor has to be a screened cable. TAE is offering premounted cables for

this purpose. Without the correct connection of the cable, the drive is not functional.

During installation, general installation regulations such as the following should be observed:

VDE 0100 General requirements for the installation of power with mains voltage up to 1000V.

VDE 0113 General requirements for the installation of electrical equipment for production and tooling machines.

VDE 0160 Requirements for electronic equipment for use in electrical power installations.

Further regulations may have to be observed if a special use for the unit is planned.

As protection equipment the following concepts could be used if allowed by your energy supplier:

Fault-Voltage-circuit-breaker (FU), protection earth or grounding (if allowed), Fault-Current-circuit-breaker (FI) can not

be used.

High leakage currents of EMC filters could trigger the protection device.

Use only functional devices. After safety equipment has been triggered, the cause must be found and the failure has

to be corrected. Defects on the device can only be repaired by TAE or from TAE authorized qualified personal.

Safety equipment must not be bypassed or removed. More information about the provided safety and protection

equipment may be found in Chapter 7.0 and 7.1.

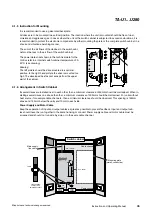

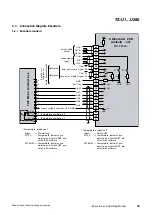

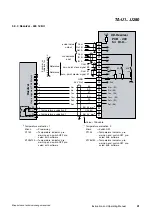

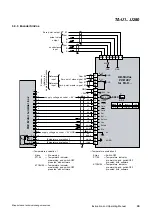

4.1.1 Switching Devices

According to the VDE regulations, the controller must be connected to mains supply line in such a manner that it can

be separated from the mains supply with suitable circuit breakers (for example main switch, circuit).

4.1.2 Arrangement of Wires

The supply cable should be a stranded conductor and not a solid conductor type to achieve proper connection

inside the terminal block. Rails for high current with their screw connection are also suited. Cable lengths inside the

wiring cabinet should be kept to a minimum.

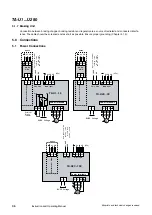

The supply cables, motor cables and control cables should never run together in the same trunking or conduit.

Keep the electronic control cables separated from the power control cables to avoid feedback. The distance should

be at least 20 cm. For the digital and analog reference and feedback cables screened cable has to be used in gene-

ral.

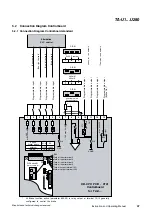

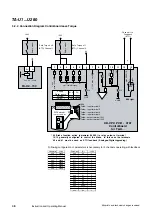

Since the cable between regulator and motor is the major source of radiated and conducted interference, it should

be a screened type and as short as possible.