Instruction and Operating Manual

TA-U1...U280

Misprints and technical changes reserved

36

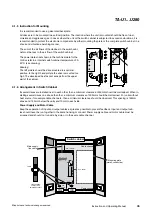

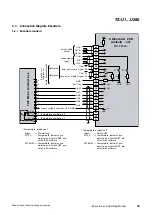

5.1.7 Braking Unit

Connection between braking chopper, braking resistor and regulator are a source of radiated and conducted interfe-

rence. The cable should be screened and as short as possible. Ensure proper grounding (Chapter 4.1.3).

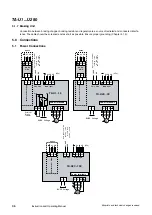

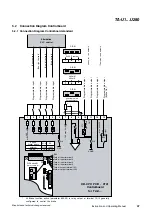

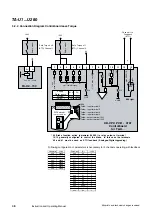

5.0 Connections

5.1 Power Connections

L1 L2 L3

L1 L2

L+ L-

+24V

0V

L3

(3Ph)

Power terminals

Main input

1+ 1-

1+ 1-

External

P

ower

Supply

L1 L2

L1 L2

UD_EX

P-S-C

U

W

M

u

v

w

V

BUSS Voltage

R2

R1

+ -

External

Brake

resistor

R

TA-U1...15

B+

B-

input

power

amplifier

opening

/

stop

for

safe

stop

24V

DC

/

30mA

Option

10A

10A

Safe Stop

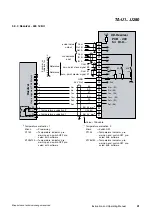

L1 L2 L3

L1 L2

L+ L-

+24V

0V

L3

(3Ph)

Power terminals

Main input

U

W

M

u

v

w

V

BUSS Voltage

+ -

TA-U22...30

Safe Stop

Input

power

amplifier

opening

/

stop

for

safe

stop

24V

DC

/

30mA

1+ 1-

1+ 1-

External

P

ower

Supply

L1 L2

L1 L2

UD_EX

P-S-C

Option

10A

10A

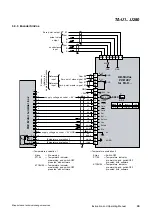

L1 L2 L3

L1 L2

L+ L-

+24V

0V

L3

(3Ph)

Power terminals

Main input

U

W

M

u

v

w

V

BUSS Voltage

+ -

TA-U37...150

Safe Stop

Input

power

amplifier

opening

/

stop

for

safe

stop

24V

DC

/

30mA

External

P

ower

Supply

L1 L2

Option

10A

10A

1L11L2