E-mail : taewoo@cutex.kr http://www.cutex.kr

- 12 -

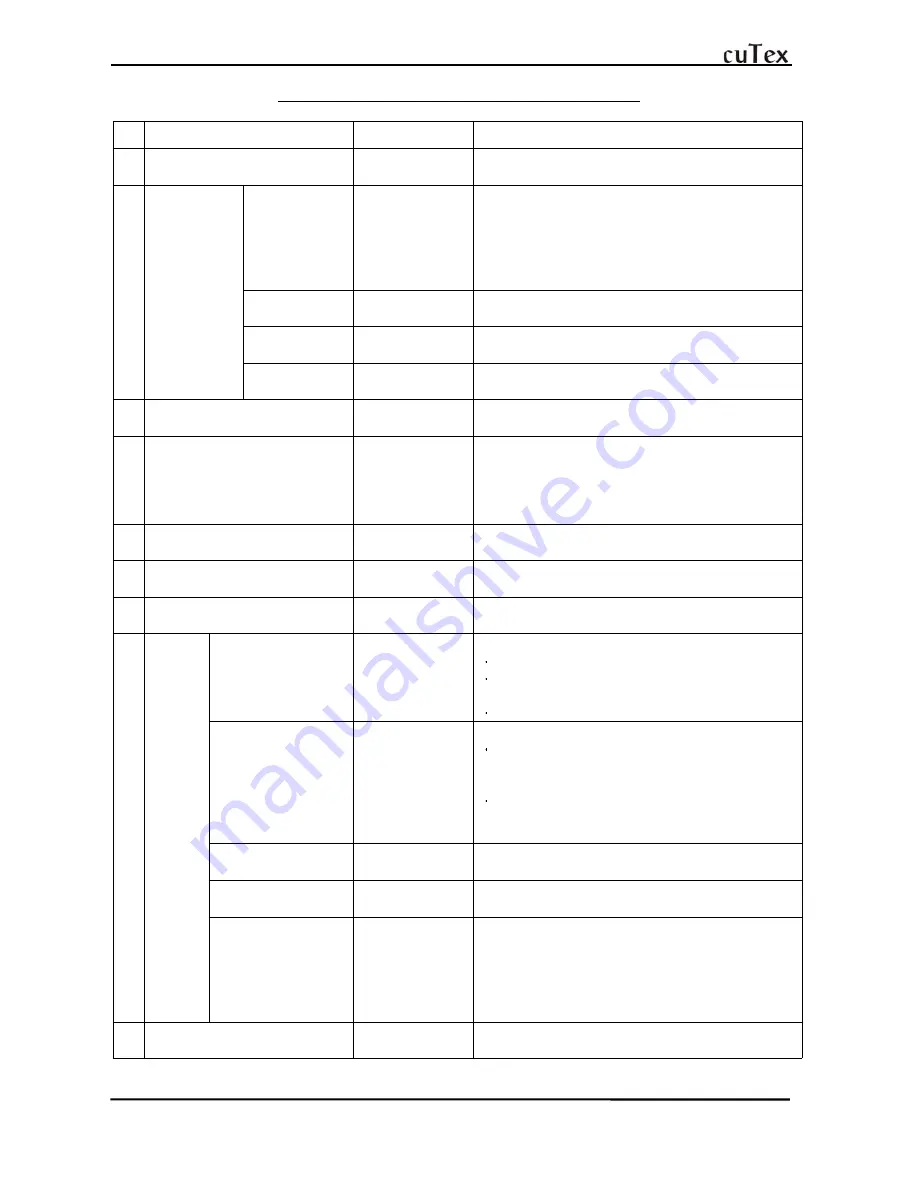

Trouble-shooting of TBC-50 series

No

Troubles

Appicable model

Causes & Measures

1 No power supply

All models

- Check if electric cord is connected well.

- Check if the fuse blows out or not.

2

Power is on,

but no work

Feeding roller

doesn't work.

All models

- Check if there is inserted any alien

substance in roller.

- If current length on display is changed,

exchange drive board.

- If current length on display is not changed,

exchange Control board(MB).

Knife doesn't

work.

All models

- Check if pressure plates of upper knife are

too much fastened or not.

LCD display

doesn't work.

All models

- After opening the cover, check the connetion.

(especially between Operation & MB board)

All functions

don't work

Al models

- Check if auto-stop device lies down. If any,

raise it up.

3 Material is not cut.

Hot cutter

(H, LH, SH, HX)

- Check if temperature goes up to set-degree.

- Check if knife blades are even(parallel).

4 Material is cut onesidedly.

All models

- Check if blades are damaged or weared.

- After making both knives close each other

by M/CUT button and check if they are even

or not. (If they are not even, adjust them by

bolts)

5

Cut-length is different from

set-length.

All models

- Test cutting after loosening material from the

reel by hand or attaching feeding device.

6

It cuts before the cutting line

of labels.

Label cutter

(S, SH)

- Move the sensor towards knife side as long

as the difference by pushing.

7

It cuts after the cutting line

of labels.

Label cutter

(S, SH)

- Move the sensor towards counter-knife side

as long as the difference by pushing.

8

ERROR

on LCD

& LED

ERROR CODE [064]

>Sensor check Er

Label cutter

(S, SH)

- Trouble in Mark sensor

→

‧

Check if the sensor is connected well or not.

‧

Check if the sensor is adjusted well or not.

(FILE NO 001)

‧

Check if it is label problem or not.

ERROR CODE [065]

>CUT I/O Error!

All models

- Trouble in cutting motor or cutting sensor

→

‧

Upper knife moves 1~3 sec. and ERROR

on display. Check the connection of cutting

sensor. If not, exchange the cutting sensor.

‧

Upper knife doesn't move and ERROR on

display. Exchange the cutting motor or drive

board.

STOP INPUT !!

CHECK STOP INP!

All models

- Auto stop device is pressed down or shortage.

→

raise up the device and check shortage.

(C)ACORD CTRL-OP

AMC-T3KA VER1.7D

All models

- Bad connected ROM

→

Press ROM by hand

or connect it again. (If not, change MB board)

ERROR CODE[065]

>CHECK CODE[003]

All models

- Change of FILE 003 in program by noise or

mis-operation

→

Initialize the controller.

※

How to Initialize(programs to be initial) :

press SET+SHIFT/ESC buttons and

RESET button at the same time.

(Press RESET later than other two keys.)

9

Operator feels electric current

in touch of machine.

All models

- Connect the earth cord(green) to any bolt of

backside of machine.

※

A/S center : TEL +82 31 521 6904~7, FAX +82 31 521 6908

Summary of Contents for cuTex TBC-50

Page 1: ......

Page 6: ...E mail taewoo cutex kr http www cutex kr 5 TBC 50 Part Drawing A Feeding part ...

Page 8: ...E mail taewoo cutex kr http www cutex kr 7 TBC 50 Part Drawing B Cutting part ...

Page 10: ...E mail taewoo cutex kr http www cutex kr 9 TBC 50 Part Drawing C Other part ...