E-mail : cutex@chol.com

http://www.cutex.kr

- 2 -

▷

Set function.(Sensor cutting: "1", Normal cutting : "0")

☞

Sensor cutting :

FILE

⇒

1

EXTRA

⇒

SE T

☞

Normal cutting :

FILE

⇒

0

LENGTH

CLEAR

⇒

SE T

▷

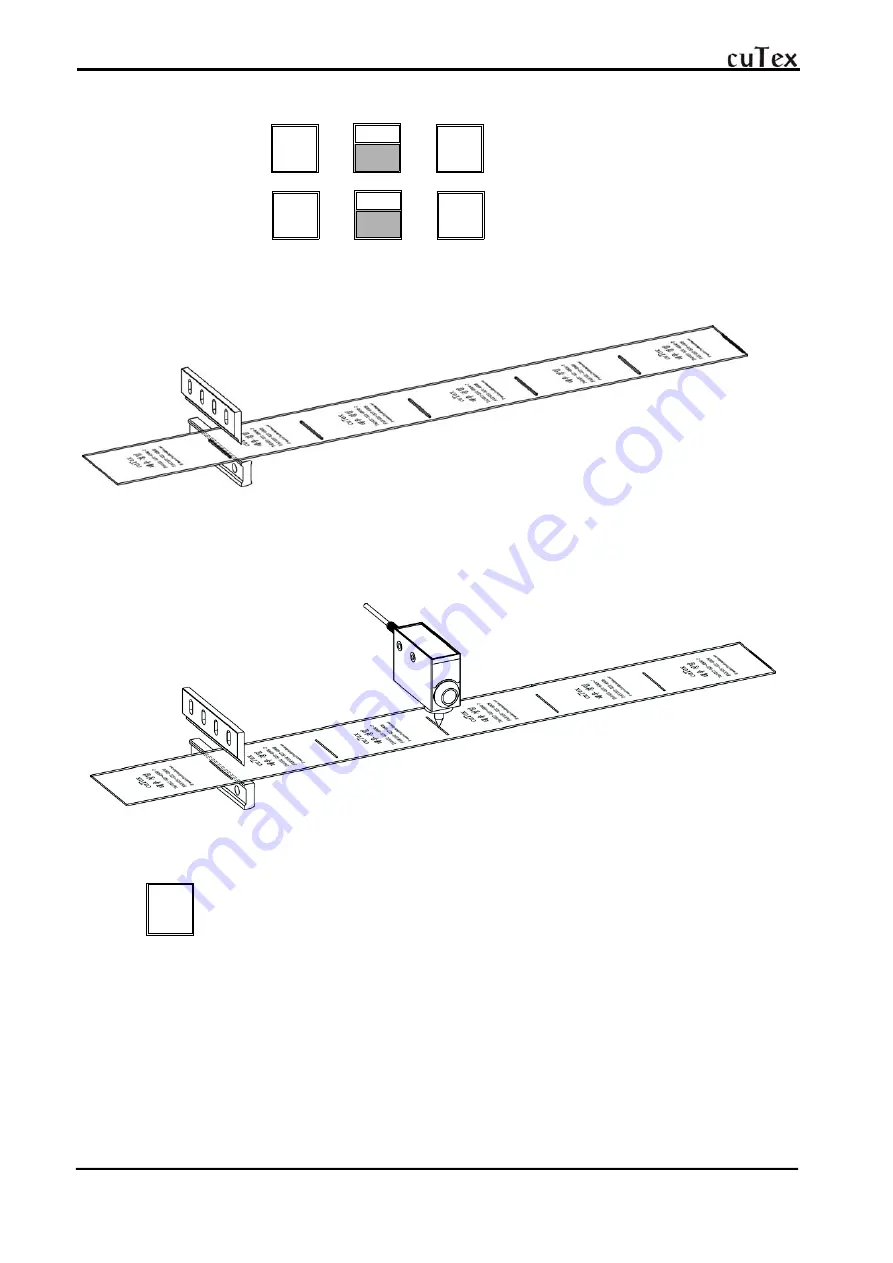

Locate the cutting line of label on the lower knife blade.

(This step must go ahead of sensor adjustment.)

▷

Sensor Adjustment

Light sensor-beam on sensing point of label.

(Refer to "How to use sensor R58 EXPERT of next page.)

▷

Press START button.

☞

START

※

Check Points for cutting trouble

- Check if you adjust sensor after locating cutting line of label on the knife blade.

- Move the sensor forwards or backwards.

- Check sensitivity & height of the sensor.

- Check if the switch is upside for elastic, downside for non-elastic including label.

Summary of Contents for cuTex TBC-50S

Page 1: ......

Page 9: ...E mail cutex chol com http www cutex kr 8 TBC 50S Part Drawing A Feeding part ...

Page 11: ...E mail cutex chol com http www cutex kr 10 TBC 50S Part Drawing B Cutting part ...

Page 13: ...E mail cutex chol com http www cutex kr 12 TBC 50S Part Drawing C Other part ...