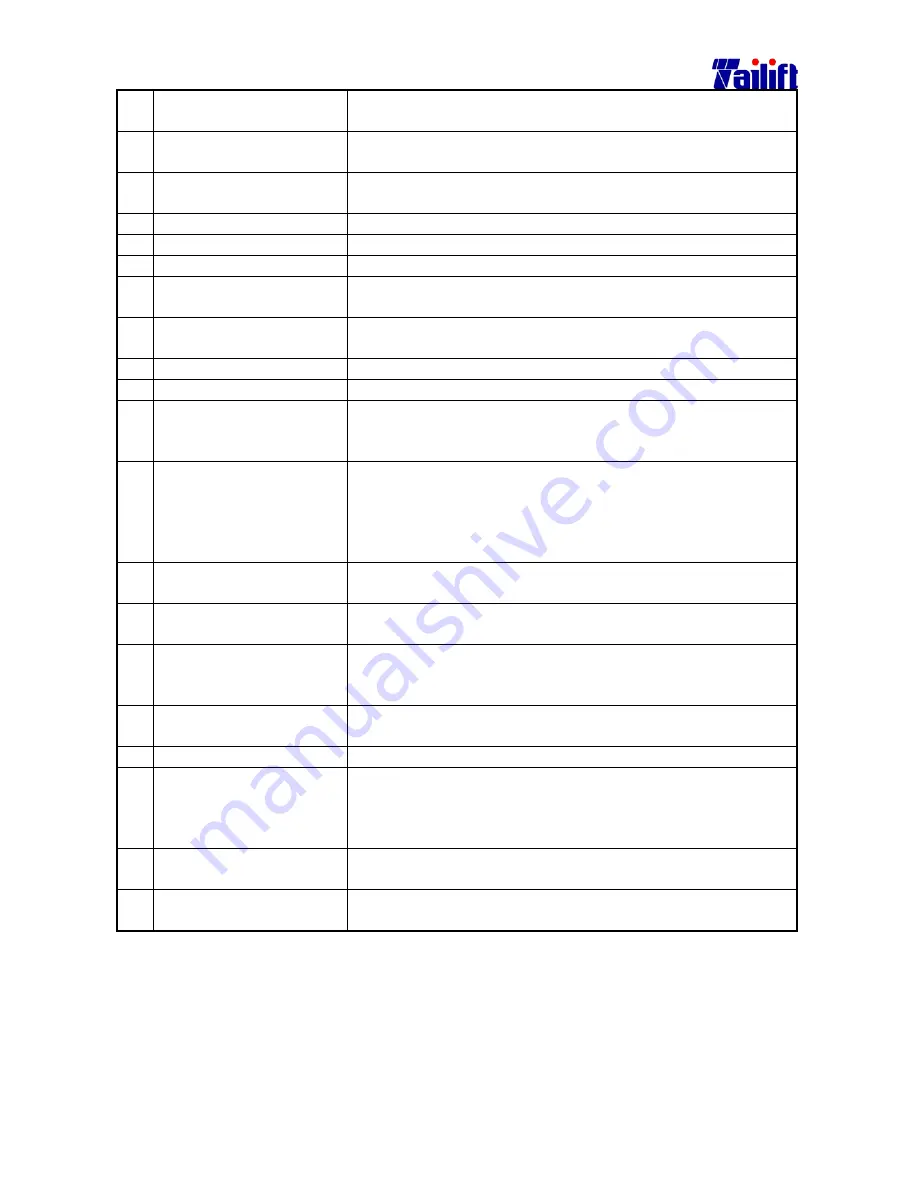

5-6

6 Hand wheel, for moving

head

It is the indicator for the automatic knife feeding. It runs

simultaneously with the feeding knives.

7 Handle, for rotating the

Arm.

It requires the smallest strength and it is the safest way to

rotate the Arm,

8 Main dial

It indicated the depth of the drilling. Its scale range is less

than 100 mm.

9 Lever, for feed trip.

It is to start or stop the automatic Knives Feeding.

10 Feed depth lever

It is to set up the position of the Main Dial and the Feed Trip.

11 Hand wheel

It is to move the head either to right or to left side.

12 Column

It is to support the Gearbox and Arm. It is connected with

the Base.

13 Top Cap

There is a motor on it, which is to move the Gearbox and

Arm up or downwards.

14 Main motor

It is to move the spindle.

15 Arm

It is to support the Gearbox, connecting with the Column.

16 Worktable

It features a T shape chamfer, which help clamp and position

work piece. In addition, the worktable helps shorten the

distance between the work piece and the drill bit.

17 Base

It is the gravity center of the machine. It stores the cutting

fluids. When no worktable used, it is used to support the

work piece and applied as a base for processing. It features

also a T shape chamfer, which is very convenient for

clamping.

18 Spindle

It is the place where drill bit, threading head, drill clamp are

mounted on.

19 Cutting fluids adjusting

knob

It is used to control the floating of the cutting fluids.

20 Feed rate switch

When at boring and automatic feeding needed, the feed rate

varies due to the different material and drilling bit used. It is

used to adjust the feed rate.

21 Electric ball screw

It is the rail of the Arm, which can be lifted or lowered by an

elevating motor.

22 Control box

All control elements are mounted here.

23 Elevating speed reducer

The elevating motor rotates very fast. If the motor drives the

ball screw transmission directly, it is very hard to control the

elevating position. Therefore an elevating speed reducer is

mounted to easily control the elevating positions.

24 Metal covering

It covers the internal Elevating motor and ball screw so that

the operator or others can be safely protected.

25 Cutting fluids pump

It is to pump the cutting fluids from the container to

lubricate the drilling or boring.

Summary of Contents for TPR1100

Page 7: ...1 6 Arm elevating motor For TPR 720A TPR 820A TPR 920A Arm elevating motor For TPR 1100...

Page 30: ...5 4 5 1 2 For TPR 1100 The front view of TPR 1100...

Page 40: ...5 14 Examples of clamping using the universal clamp...

Page 81: ...9 6 9 6 Electrical Circuit Diagram For TPR720A TPR820A TPR920A Standard...

Page 84: ...9 9 9 8 Electrical Circuit Diagram For TPR1100 Standard...