0-1

Section

Content

page

CHAPTER 1 Safety Guidelines

….………………………………………………..

1-1

1.1

Please follow the below basic safety principles..………………………..

1-1

1.2

Precautions for the transportation and installation..……………………..

1-1

1.3

Precautions for operation....……………………………………………..

1-2

1.4

Precautions for checking and maintenance...……………………………

1-2

1.5

Warning labels and mark on the machine……………………………….

1-3

1.5.1 Warning labels and mark introduction ………………………………….

1-3

1.5.2 Labels Warning labels and mark positions ……………………………...

1-4

CHAPTER 2 General specifications

………………………………………….…..

2-1

2.1

The anticipated machine life..…………………………………………...

2-1

2.2

Machine dimensions..…………………………………………………...

2-1

2.3

The machine...…………………………………………….……………..

2-2

2.3.1 Description….………………………………………………………..….

2-2

2.3.2 Parts...……………………………………………………………………

2-2

I For TPR-720A, TPR-820A, TPR-920A ………………………….

2-2

II only for TPR-1100………………………………………………..

2-3

2.4

S

pecifications ………………………………………………………….

2-4

2.4.1 TPR-720A ……………………………………………………………...

2-4

2.4.2 TPR-820A Specification ..……………………………………………...

2-5

2.4.3 TPR-920A specification ……………………………………………….

2-6

2.4.4 TPR-1100 specification ……………………………………………….

2-7

2.5

S

tandard and Option Accessories….…………………………………….

2-8

2.6

Operation position and noise level...…………………………………….

2-8

2.6.1 Operation position……………………………………………………….

2-8

2.6.2 The noise level...………………………………………………………...

2-8

CHAPTER 3 Preparation to install

………………………………………………

3-1

3.1

Space and room requirement……………………………………………

3-1

3.1.1 Floor requirement………………………………………………………..

3-1

3.1.2 Space requirement...……………………………………………………..

3-2

3.2

Environment requirement...……………………………………………..

3-3

3.3

Power supply requirement...…………………………………………….

3-3

3.4

Electric system calculation……………………………………………...

3-4

CHAPTER 4 Transportation and Installation

….……………………………..

4-1

4.1

Disassembly and packaging..……………………………………………

4-1

4.1.1 General…………………………………………………………………..

4-1

4.1.2 Packaging………………………………………………………………..

4-1

Summary of Contents for TPR1100

Page 7: ...1 6 Arm elevating motor For TPR 720A TPR 820A TPR 920A Arm elevating motor For TPR 1100...

Page 30: ...5 4 5 1 2 For TPR 1100 The front view of TPR 1100...

Page 40: ...5 14 Examples of clamping using the universal clamp...

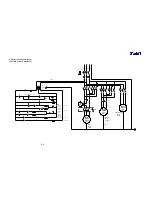

Page 81: ...9 6 9 6 Electrical Circuit Diagram For TPR720A TPR820A TPR920A Standard...

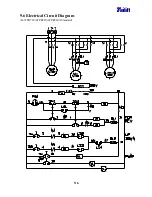

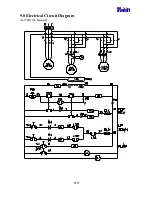

Page 84: ...9 9 9 8 Electrical Circuit Diagram For TPR1100 Standard...