0-3

Section

Content

page

5.12

Automatic Feed...………………………………………………………..

5-28

5.12.1 Automatic feed rate table………………………………………………..

5-28

5.12.2 Change the feed rate as the following way……………………………...

5-28

5.12.3 Suppose that the work piece is by the machine.………………………...

5-28

5.12.4 How to preset the depth of the power-feed..…………………………….

5-29

I (For TPR-720A, TPR-820A, TPR-920A)...……………………………

5-29

II (For TPR-1100)...…….………………………………………………...

5-30

5.13

The spindle………………………………………………………………

5-31

5.14

Threading.……………………………………………………………….

5-31

5.15

The assembly and disassembly of the work table...……………………..

5-32

5.16

Cutting fluids for all kinds of material…………………………………..

5-32

CHAPTER 6 Adjustment…

………………………………………………………..

6-1

6.1

General...………………………………………………………………...

6-1

6.2

The arm clamping lever….……………………………………………...

6-1

6.3

The gap adjustment between the gearbox and the arm rail……………...

6-2

6.3.1 (For TPR-720A, TPR-820A, TPR920A)………………………………..

6-2

6.3.2 (For TPR-1100)….………………………………………………………

6-3

6.4

Adjust the engagement between the feed trip lever and the clutch……...

6-4

CHAPTER 7 Maintenance

………………………………………………………….

7-1

7.1

General…………………………………………………………………..

7-1

7.2

Daily Maintenance..……………………………………………………..

7-1

7.2.1 Clearing...………………………………..………………………………

7-1

7.2.2 Please clean every parts using a metal brush and a rag, dipped with oil,

to rub them ……………………………………………………………...

7-1

7.2.3 The way to clean iron filings..…………………………………………..

7-2

7.2.4 Lubrication..……. ………………………………………………………

7-3

7.2.5 Change oil inside of the speed reduction of the arm elevating motor…..

7-4

7.2.6 Chang the oil inside the gearbox...………………………………………

7-5

7.3

Replace the cutting fluids………………………………………………..

7-6

7.4

Maintenance and replacement period….………………………………..

7-7

7.5

Waste disposition..………………………………………………………

7-7

CHAPTER 8 Troubleshooting

…………………………………………………….

8-1

8.1

The spindle overloads and the relay jumps...……………………………

8-1

8.1.1 The cause..………..……………………………………………………..

8-1

8.1.2 The solution..………..…………………………………………………..

8-1

8.2

The spindle overloads and the fuse burns out….………………………..

8-1

Summary of Contents for TPR1100

Page 7: ...1 6 Arm elevating motor For TPR 720A TPR 820A TPR 920A Arm elevating motor For TPR 1100...

Page 30: ...5 4 5 1 2 For TPR 1100 The front view of TPR 1100...

Page 40: ...5 14 Examples of clamping using the universal clamp...

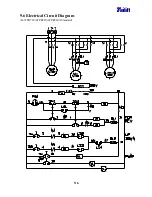

Page 81: ...9 6 9 6 Electrical Circuit Diagram For TPR720A TPR820A TPR920A Standard...

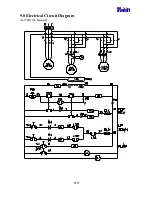

Page 84: ...9 9 9 8 Electrical Circuit Diagram For TPR1100 Standard...