5-9

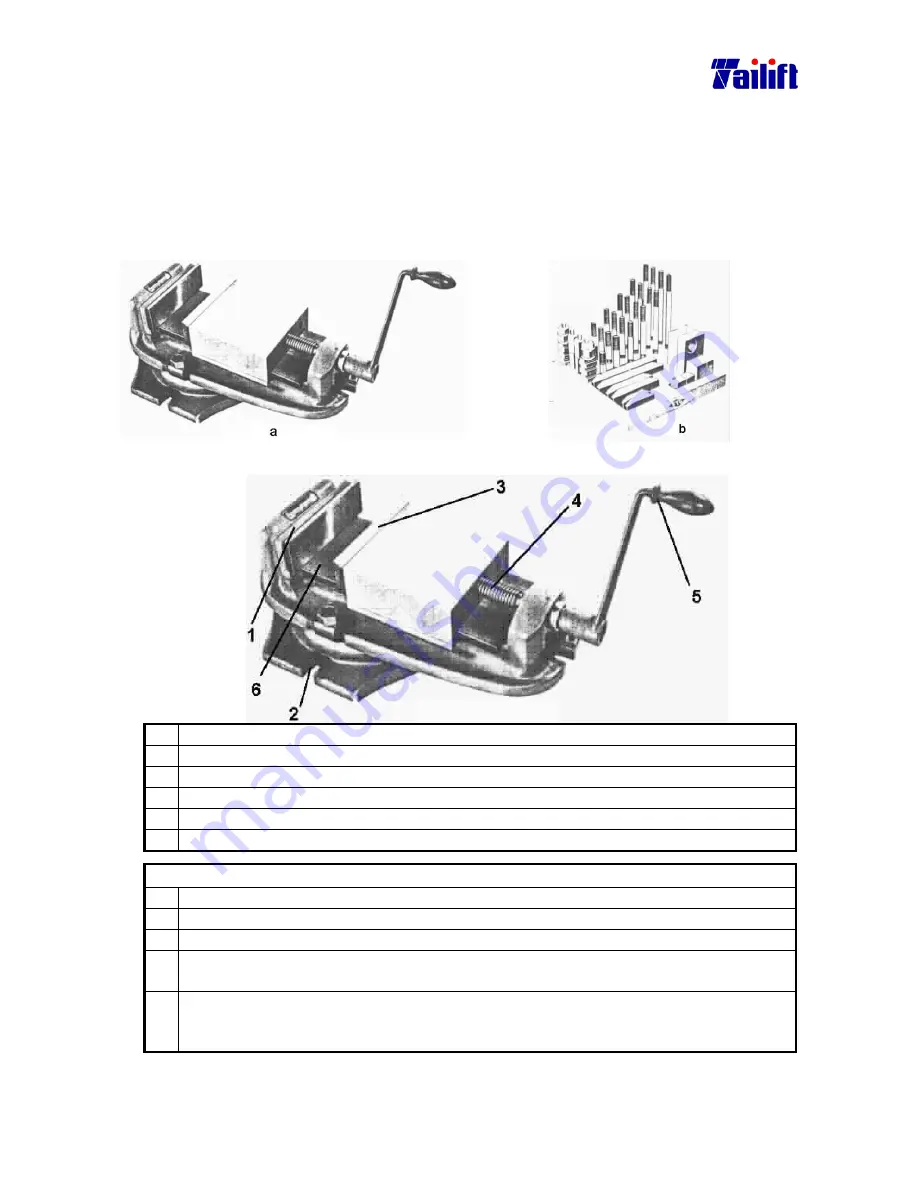

5.3 Installation of the clamp

(

work piece

)

5.3.1 General

Work piece must be placed securely and precisely on the radial drill so that precision and

safe procession can be achieved. Regularly, a vise is applied. (as shown picture a). Since

the vise has its range limit, universal clamp (as shown picture b) is applied for bulky

work piece or any work piece which isn’t easy to be clamped. The universal clamp

includes T shape chamfer bolts, stacking plate, insertion blocks, which makes clamping

easier.

5.3.2 Introduction of the vise and the clamping of the work piece.

(1) The fixed side of the vise.

(2) The fixing side with T shape chamfer bolt and nuts

(3) The moving side of the vise.

(4) The screw bar.

(5) The

handle.

(6) The surface of the vise.

Clamp work piece as the following

:

a.

Move away the drilling bit or lift the gearbox to the utmost point.

b.

Using brush, clean the worktable and the vise surface.

c.

Clean the vise surface using clean rag.

d.

Position the work piece on the vise surface. If it is piercing drilling, please insert a

block under the work piece so that drilling into vise can be avoided.

e.

Fasten the handle by rotating it clockwise and tighten it. While tightening it, please

use plastic hammer or copper bar to hit the work piece till there is no gap between

the work piece and the inserted block.

Summary of Contents for TPR1230

Page 11: ...1 6 z Gearbox For TPR 1230 TPR 1230H For TPR 1600H TPR 2000H z Hydraulic oil pump...

Page 74: ...9 4 9 4 Electrical circuit diagram For TPR 2000H CE Standard...

Page 83: ...9 13 9 9 Electrical circuit diagram For TPR 1230 Standard...

Page 84: ...9 14 9 10 Electrical circuit diagram For TPR 1230H Standard...

Page 85: ...9 15 9 11 Electrical circuit diagram For TPR 1600H TPR 2000H Standard...