5-20

5.11.2

(

For TPR-1600H/ TPR-2000H

)

Ⅰ

.Speedometer

(

For TPR-1600H/ TPR-2000H

)

Two step choice

1

2

H (hi-speed)

1890 1010 475 220 115 55

Speed

(

rpm

)

L

(lo-speed)

1330 715 335 155 80 35

Mild steel

∅

1-

∅

6

∅

6-

∅

24

∅

14-

∅

24

∅

24-

∅

36

∅

36-

∅

50

∅

50-

∅

66

Applicable

diameter mm

Cast iron

∅

1-

∅

8

∅

8-

∅

18

∅

18-

∅

30

∅

30-

∅

44

∅

44-

∅

60

∅

60-

∅

78

Ⅱ

. speed switch

(

For TPR-1600H/ For TPR-2000H

)

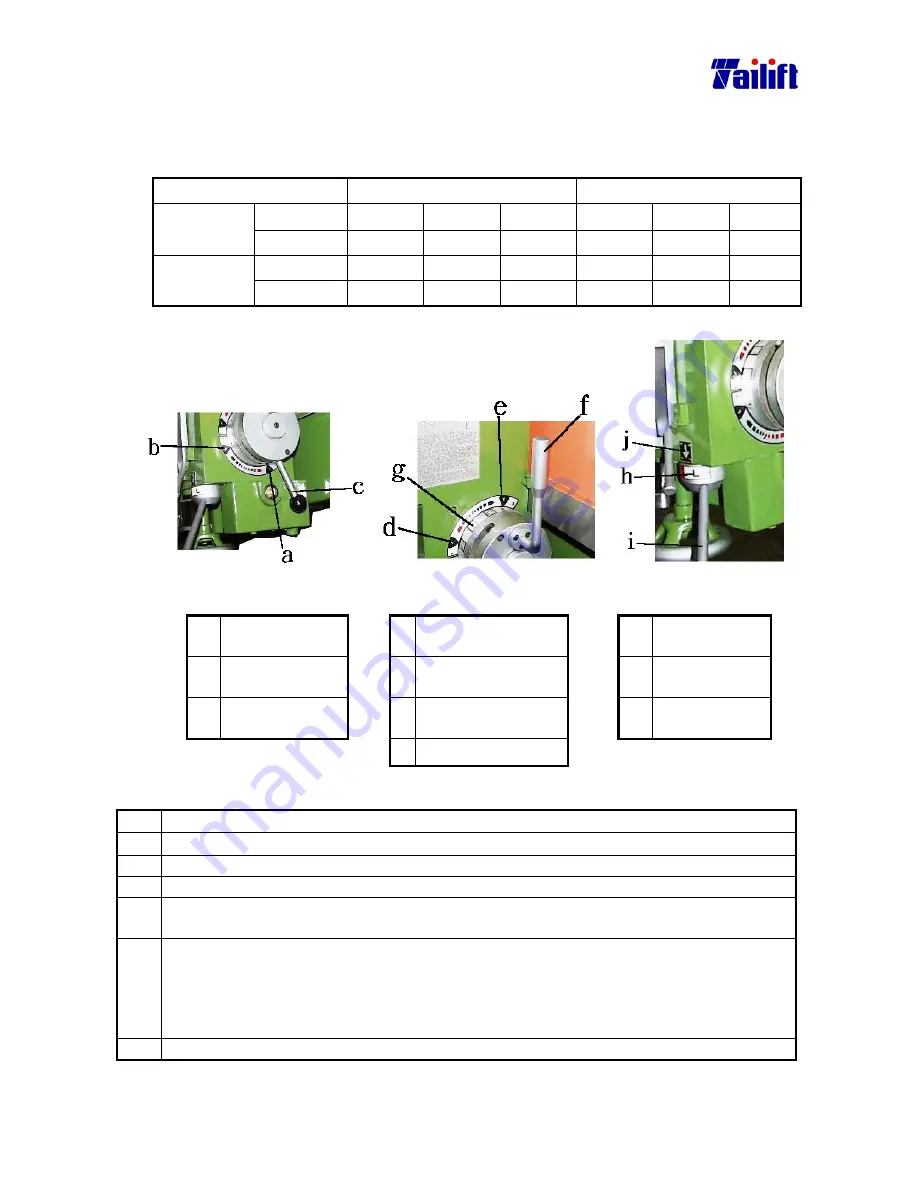

Fig.1.

Fig.2. Fig.3.

The relevant names

The relevant names

The relevant names

a. Step

1

d. Ref. Point for the

step 1.

h.

Hi-lo

speed

indicator

b. Step

2

e. Ref. Point for the

step 2.

i.

Hi-lo

speed

changing lever

c. Two speed lever

f. Three step speed

changing lever

j.

Hi-lo

speed

reference point

g. Speedometer

(

FOR TPR-1600H/ TPR-2000H

)

The way to switch speed follows as:

Step Description

a. Stop rotation of the spindle.

b. Press down the emergency button.

c. Check the speedometer and select the suitable speed.

d. Switch the two step speed changing lever (as mark c in the fig. 1.) to the required

position. (Select the required step)

e. Switch the three step speed changing lever to the required position. When the two step

speed changing lever is at the step 1, the speed will be based on the reference point of

the step 1 (as mark d in the fig. 2). On the contrary, when the two step speed changing

lever is at the step 2, the speed will be based on the reference point of the step 2 (as

mark e in the fig. 2).

f. Switch the Hi-lo speed changing lever to the required position.

Summary of Contents for TPR1230

Page 11: ...1 6 z Gearbox For TPR 1230 TPR 1230H For TPR 1600H TPR 2000H z Hydraulic oil pump...

Page 74: ...9 4 9 4 Electrical circuit diagram For TPR 2000H CE Standard...

Page 83: ...9 13 9 9 Electrical circuit diagram For TPR 1230 Standard...

Page 84: ...9 14 9 10 Electrical circuit diagram For TPR 1230H Standard...

Page 85: ...9 15 9 11 Electrical circuit diagram For TPR 1600H TPR 2000H Standard...