6-1

CHAPTER 6

Adjustment

6.1General

Adjustment is needed after the machine has been used a period of time for its parts will

get loose or worn out, In the radial drill, there are three parts needed to be adjusted. One is

the arm clamping lever, another the gap between the gearbox and the arm rail, finally the

engagement between the feed trip lever and the clutch.

6.2 The arm clamping lever

After the machine has been used for about 3-5 years, the position of the arm clamping

lever will be descending. It is the time to adjust the position of the adjusting nut.

6.2.1(For TPR-1230, TPR-1230H)

Fig. a.

Fig. a-1

Fig. b.

Fig. c.

The relevant names

The relevant names

No. name

No.

name

1. Release

switch

3.

Adjusting nut

2. Clamping

switch

4.

Fastening nut

Adjust the arm clamping lever as follows:

a. Press the figure1 shown in the bottom. Referring to the up right picture, release the

button after pointing the arrow head to b. The clamping device is released now.

b. Release the fastening nuts, totally 5 pieces, in the figure c and mark 4.

c. Using a wrench, adjust the nuts counter clockwise about 180°. (totally 5 pieces bolts)

d. Fasten the nuts, marked 4 in the figure c. (totally 5 pieces bolts)

e. Press the figure2 shown in the bottom left picture 1. Referring to the up right picture,

release the button after pointing the arrowhead to A. The clamping device is tightened

now.

Summary of Contents for TPR1230

Page 11: ...1 6 z Gearbox For TPR 1230 TPR 1230H For TPR 1600H TPR 2000H z Hydraulic oil pump...

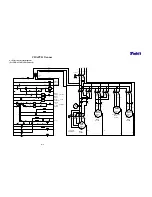

Page 74: ...9 4 9 4 Electrical circuit diagram For TPR 2000H CE Standard...

Page 83: ...9 13 9 9 Electrical circuit diagram For TPR 1230 Standard...

Page 84: ...9 14 9 10 Electrical circuit diagram For TPR 1230H Standard...

Page 85: ...9 15 9 11 Electrical circuit diagram For TPR 1600H TPR 2000H Standard...