6-7

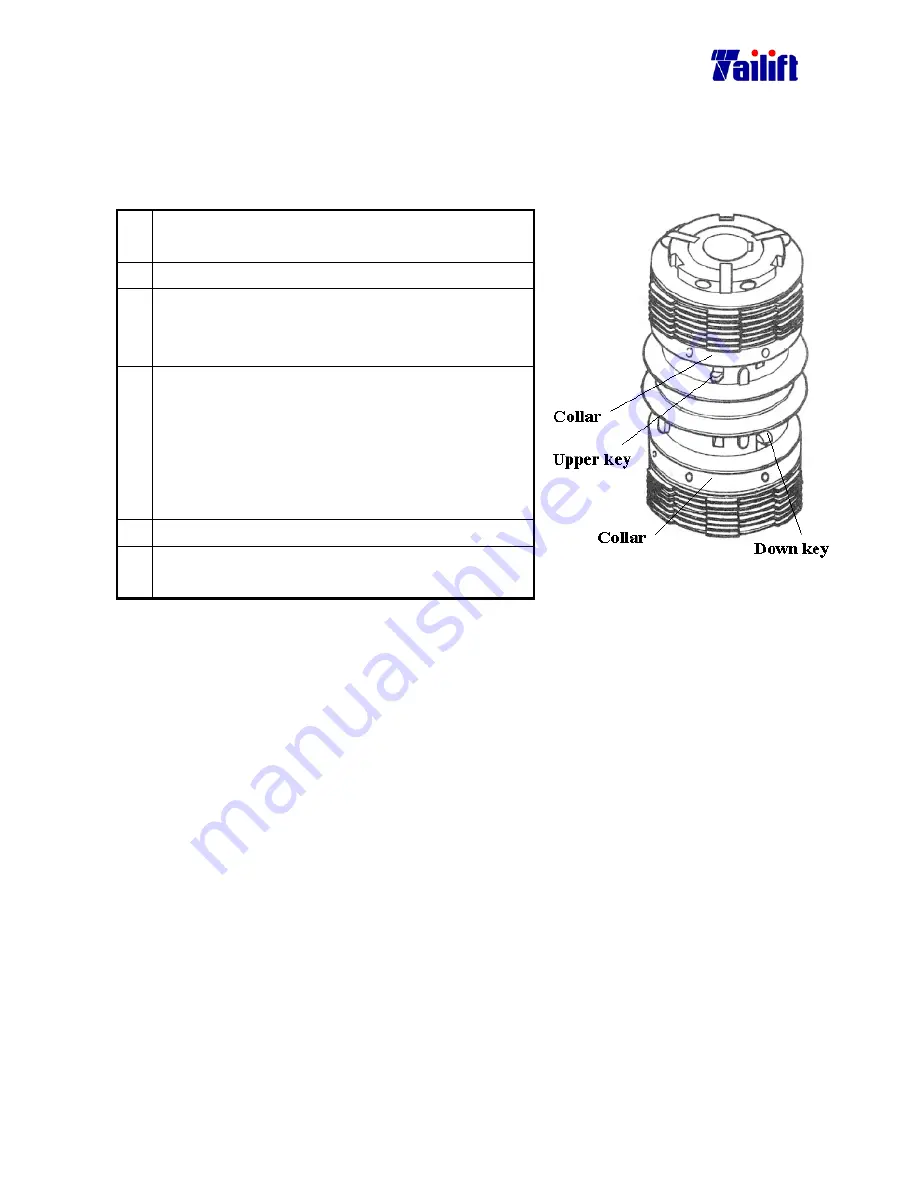

6.7 Adjustment of the clutch(for TPR-1600H/TPR-2000H)

While the spindle can’t rotate fully to drill, the clutch is wear to drill, the clutch is wear to

drill,the clutch is weared, you can adjust device, as following.

a.

Change gear speed to the highest speed, turn off

power.

b.

Remove oil sight glass.

c.

Rotae spindle by your left-hand until clutch turns to

the best position for adjustment, clutch’s key faces

outside.

d.

Push upper key(down key) out, turn collar

right(left) a little for adjustment, until the key

comes back notch automatically.

* If clutch “L”(“H”) speed can’t rotate fully while

drilling, you should adjust upper key

(down key)

e.

Put oil sight glass.

f.

Operate spindle to drill, check if sindle can rotate

while drilling.

Summary of Contents for TPR1230

Page 11: ...1 6 z Gearbox For TPR 1230 TPR 1230H For TPR 1600H TPR 2000H z Hydraulic oil pump...

Page 74: ...9 4 9 4 Electrical circuit diagram For TPR 2000H CE Standard...

Page 83: ...9 13 9 9 Electrical circuit diagram For TPR 1230 Standard...

Page 84: ...9 14 9 10 Electrical circuit diagram For TPR 1230H Standard...

Page 85: ...9 15 9 11 Electrical circuit diagram For TPR 1600H TPR 2000H Standard...