- 6 -

TM

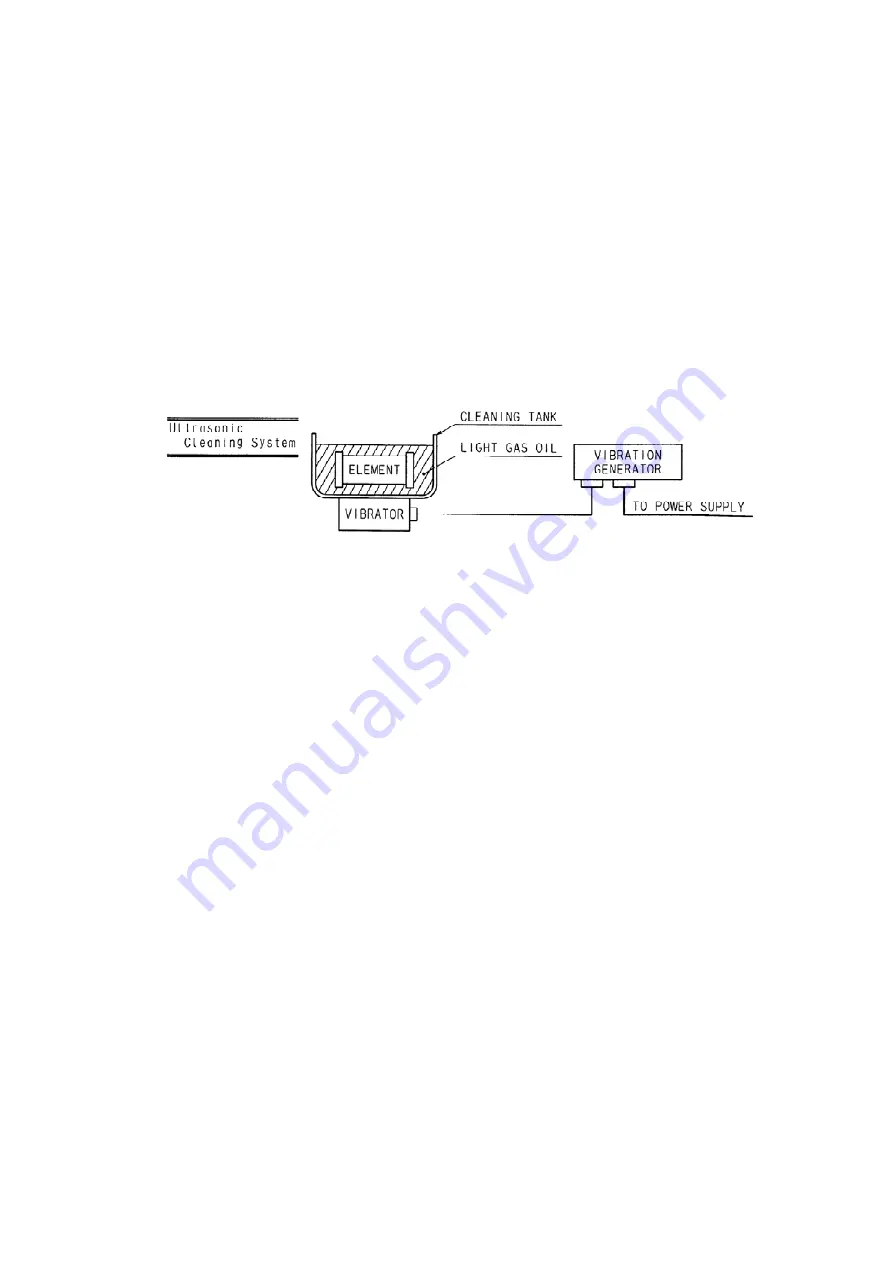

9-3. Cleaning Filter Element

Clean the filter element with light oil (kerosine, gas oil, etc.) in the

following manner.

(1) Shake the filter element in four directions in the cleaning oil.

(2) Brush the filter element carefully to remove sludge.

(3) Blow off residual accumulations with an air spray.

(4) Rinse the filter element well and dry with an air spray.

《 Note》

The above way of cleaning is effective for wire gauze filter elements up to 40

microns in mesh size. In the case of wire gauze filter elements below 25 microns,

remove surface accumulations mostly by the above method and clean completely by

ultrasonic cleaning without fail.

In the cleaning tank, place the top and bottom of the filter element on the

vibrator side alternately and clean. While it depends on the capacity of the

ultrasonic cleaning equipment and the amount of sludge on the element,

the cleaning time should be at least 1 hour.

1 0 . R E P L A C E M E N T

P A R T S

Keep the following parts available for replacement at any time.

And Replace the seal parts ④ ,⑤ ,⑥ ,⑩ with new ones.

■ Spare filter element

■ "O"Rings and Backup ring

※ Refer to the accompanying drawing for details.

Summary of Contents for TM

Page 8: ......