92

Circuit Descriptions

TM9100 Service Manual

© Tait Electronics Limited

August 2005

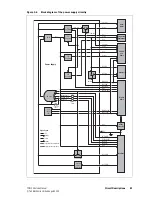

Power Supply

A 3.3 V regulator (U1) converts the switched 13.8V supply from the radio

body to 3.3 V. A 1.5 V regulator (U203) converts the 3.3 V to 1.5V.

A power-sense module (U202) verifies the outputs of the voltage regulators

and—in the case of a fault—creates a power reset signal which is processed

by the FPGA.

Volume Control

The voltage level of the volume control potentiometer is converted to a

digital signal by an analog/digital converter (U601), processed by the FPGA

and transmitted to the radio body.

Main Keypad

The eight keys of the main keypad (function, scroll and selection keys) are

connected to the FPGA by an array of 3 columns and 3 rows. During idle

operation, the

KEY ROW

signals are driven low by the FPGA and the

KEY COL

signals (pulled high by an external resistor) are monitored for activity by the

FPGA. A key-press will generate a high-to-low transition on the associated

column

KEY COL

signal. This, in turn, will initiate a sequence of high output

levels on the

KEY ROW

signals to identify which key was pressed.

LCD Module

The LCD module is connected to the control-head board via the LCD

connector. The LCD module display is controlled by a serial data link to the

FPGA. The backlighting and the optional heating element incorporated in

the LCD module are controlled by a data line each from the FPGA, which

switch two transistors on MOSFET Q102. A temperature signal from the

LCD module is converted to a digital signal by an analog/digital converter

(U601) and processed by the FPGA.

Function Key LEDs

and Status LEDs

The function key LEDs (

F1

and

F4

) and the red, green and amber status

LEDs each are controlled by an FPGA signal and a transistor (Q604 to

Q608). The brightness level is controlled by two FPGA signals, resulting in

four intensity levels (off, low, medium and high).

Keypad

Backlighting

The keypad backlighting LEDs are controlled by two FPGA signals and two

transistors (Q2), resulting in four intensity levels (off, low, medium and

high). The keypad backlighting LEDs are arranged in two groups for the

main keypad and one group for the power button keypad, each group

consisting of three LEDs.

Speaker

The two speaker lines (SPK+ and SPK–) are connected to the speaker

connector (J104) which is joined to the control-head connector (J103)

through two ferrite beads (L105 and L106).

Microphone and

Concealed

Microphone

The audio signals from the microphone connector or the soldering pads of

the concealed microphone are routed to a switching and pre-amplifier

circuit. If a dynamic microphone is required, the pre-amplifier is engaged.

The switching logic is used to select either the standard microphone input

or the concealed microphone signal. The dynamic microphone must be

activated in the programming software.

PTT

The PTT signal from the microphone connector is connected to the FPGA

via a resistor (R25) and relayed to the radio as a digital command.

Summary of Contents for TM9100

Page 1: ...TM9100 mobiles Service Manual MMA 00017 01 Issue 1 August 2005 ...

Page 4: ...4 TM9100 Service Manual Tait Electronics Limited August 2005 ...

Page 10: ...10 TM9100 Service Manual Tait Electronics Limited August 2005 ...

Page 22: ...22 Introduction TM9100 Service Manual Tait Electronics Limited August 2005 ...

Page 62: ...62 Description TM9100 Service Manual Tait Electronics Limited August 2005 ...

Page 96: ...96 TM9100 Service Manual Tait Electronics Limited August 2005 ...

Page 138: ...138 Disassembly and Reassembly TM9100 Service Manual Tait Electronics Limited August 2005 ...

Page 152: ...152 Servicing Procedures TM9100 Service Manual Tait Electronics Limited August 2005 ...

Page 168: ...168 Interface Fault Finding TM9100 Service Manual Tait Electronics Limited August 2005 ...

Page 244: ...244 Receiver Fault Finding TM9100 Service Manual Tait Electronics Limited August 2005 ...

Page 396: ...396 CODEC and Audio Fault Finding TM9100 Service Manual Tait Electronics Limited August 2005 ...

Page 420: ...420 Fault Finding of Control Head TM9100 Service Manual Tait Electronics Limited August 2005 ...

Page 426: ...426 Spare Parts TM9100 Service Manual Tait Electronics Limited August 2005 ...

Page 430: ...430 TM9100 Service Manual Tait Electronics Limited August 2005 ...

Page 444: ...444 TMAA04 05 Ignition Sense Kit TM9100 Service Manual Tait Electronics Limited August 2005 ...

Page 448: ...448 TMAA10 01 Desktop Microphone TM9100 Service Manual Tait Electronics Limited August 2005 ...