10

3.3 STARTING UP:

Before each machine startup, it is necessary to check the chain tension and readj

ust it if necessary!

A too loose chain can induce vibrations, which unfavorably affect the drive belt’s operation. Increased vibrati-

ons can also cause damages to the drive belt. A new cutting chain need

s

to be retensioned after approx. half an

hour of use. Please check.

Check the oil levels of the hydraulic system and cutting chain lubrication system, before starting the machine!

•

Examine the machine and equipment for faults and check the chain lubrication

•

Place the tractor manual throttle handle in lowest position.

•

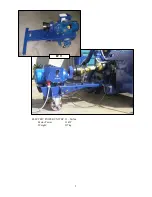

Lift the machine cover (B-Figure: 1a) to activate the safety switch and disengage all maj

or machine func-

tions.

•

Slowly engage the P.T.O. shaft drive and start the machine.

•

Set the required rotating speed of P.T.O. shaft (420 RPM), using the manual throttle handle.

•

Lower the machine cover.

RCA 320-2 :

RCA 320-

2

E:

•

Examine the machine and equipment for faults and check the chain lubrication

•

Plug the machine to electric power source

•

Turn on the

Main Switch

(R-Figure: 1)

•

Lift the

machine cover

(B-Figure: 1) to activate the safety switch and allow easier starting of the electric

motor

•

Push the “

Start-Stop

” switch (green button) (S-Figure:1) and

immediately check the rotating direction

of the cutting chain:

in case of wrong cutting chain direction, immediately stop the drive (push the red

button on the “

Start-Stop

” switch and change the rotating direction of the electric motor (Chapter: 3.)

•

Lower the machine cover

Remove all wood remains and other particles from the splitting chute, before starting the machine!

Before starting the machine, make sure to loosen the conveyor belt, by moving the Discharge Conveyor from

vertical to horizontal position using the hand winch (3-Figure:3). Otherwise damages to the belt can occur

during the extension procedure!