14

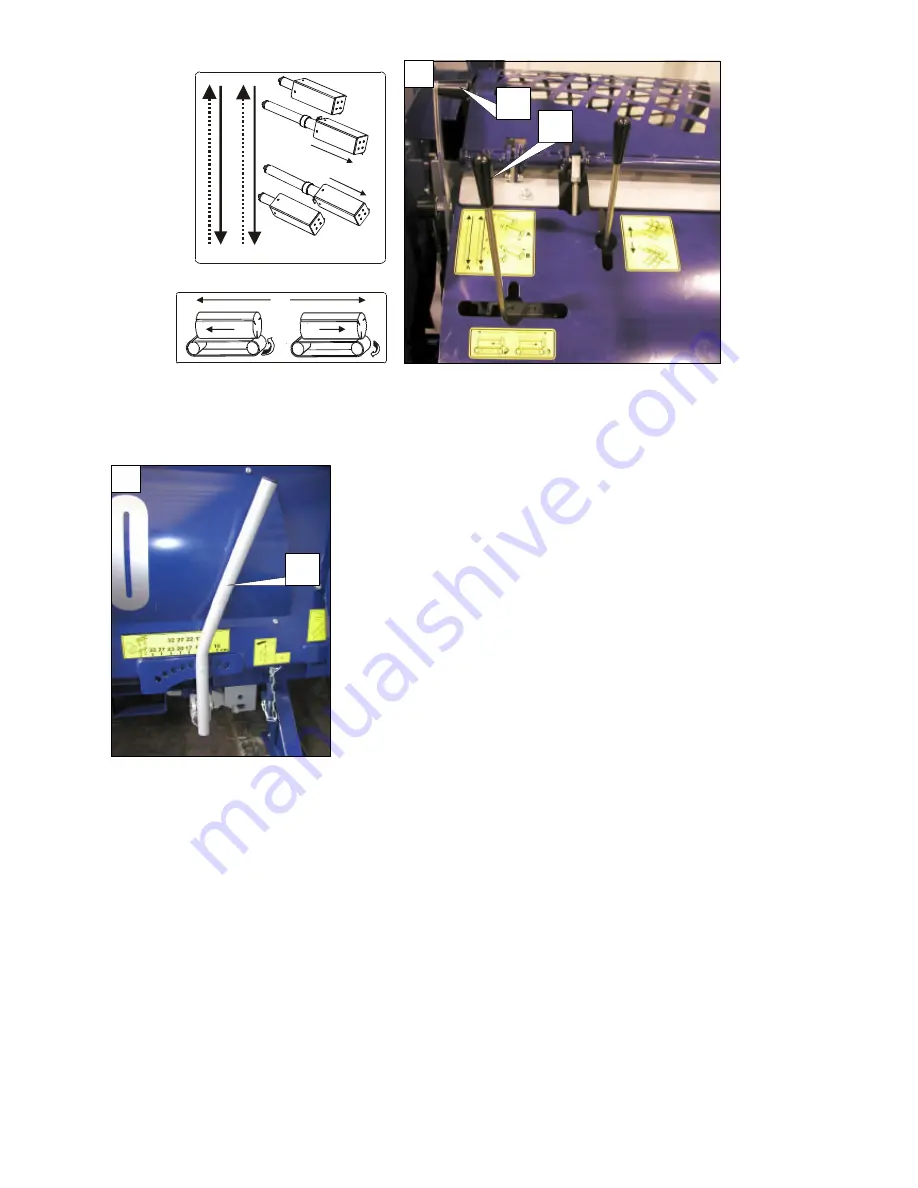

4.4.1 ADJUSTING THE HEIGHT OF THE SPLITTING WEDGE

By using a splitting wedge handle (L-Figure: 10), the splitting wedge

can be gradually lifted or lowered depending on the diameter of the logs

- so the logs are split in center.

Splitting wedge adjustment can be performed most easily when the split-

ting chute is empty or at the point when the splitting cylinders start to

move.

Lifting mechanism of the splitting wedge also allows partial height

movements of the splitting wedge during the splitting phase. In case the

wood gets stuck under the splitting wedge it must be removed to prevent

damage to the lifting mechanism of the splitting wedge (Refer to chapter

5.11, indications of overload… ).

10

L

4.4.2MACHINE COVER WITH SAFETY SWITCH

In case of eventual problems during the splitting phase, or in case the log is wrongly positioned in the splitting

chute, the splitting process must be

stopped

immediately. In this case it may be also necessary to switch the

cylinders, so the splitting cylinder which pushes towards the splitting wedge, moves back (4.4).

Machine cover (B-Figure: 11) is linked to the safety switch, which disengages all major machine functions

when the machine cover is lifted: in-feed and discharge conveyors stop, splitting cylinders stop and sawbar is

withdrawn into the saw shield. Lifting the machine cover therefore acts also as a main safety switch.

The log can be reached by hand only when the machine cover is opened and machine is stopped. Sawing and

splitting cannot continue until the machine cover is closed and safety switch disengaged.

9

S

C