7

2 SAFETY INSTRUCTIONS

•

Machine operation and maintenance is allowed to qualified persons older then 18 years of age, only!

•

Before starting the work, the machine must be placed in a stable position,!

•

Use only P.

T.

O.

shafts of appropriate strength (min.

25 kW ), with undamaged outer plastic protective

cover (RCA 320-2)!

•

Never use damaged, cracked or deformed cutting chains!

•

Always wear personal protective equipment (safety glasses, hearing protectors, gloves and forestry

boots)!

•

W hen troubleshooting, replacing the chain or any service procedure, always disengage P.

T.

O.

shaft and

shut down the tractor (RCA 320-2)

or unplug the power cord from the electrical outlet (RCA 320-2 E)!

•

Do not wear loose clothes!

•

Keep the working environment clean and tidy!

•

Always use caution when operating the machine! Rotating chain can cause serious inj

uries in case of

incorrect use of the machine.

•

Never leave the machine running without supervision!

•

Do not reach into the working area, while the machine is in operation!

•

Before removing a wedged piece of wood, shut down the machine drive (RCA 320-2) or turn off the

machine using »START

-STOP«

Swi

t

ch

(

RCA

320-2

E)!

•

W hen

t

ransport

i

ng

t

he

machi

ne

on

publ

i

c

roads

i

t

i

s

necessary

t

o

i

nst

al

l

l

i

ght

s

on

t

he

read

end

of

t

he

machi

ne!

•

For

your

own

saf

et

y

use

onl

y

ori

gi

nal

spare

part

s

and

accessori

es

whi

ch

are

approved

by

t

he

manuf

ac-

t

urer!

•

The

machi

ne

must

be

grounded

accordi

ng

t

o

regul

at

i

ons

(

RCA

320-2

E)

!

•

Damaged

power

cord

or

pl

ug

must

be

repl

aced

i

mmedi

at

el

y

(

RCA

320-2

E)!

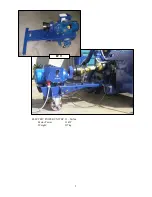

3 M ACHINE

SETUP

AND

OPERATION

•

Mount the firewood processor to the three-point tractor system using bol

ts.

Lower tractor connecting han-

dl

es must be fixed with tensioning screws,

so the machine can move transversel

y.

W hen transporting the

machine,

consider the weight of the whol

e machine (Chapter 1.

5).

•

Connect the P.

T.

O.

shaft to the cardan shaft and

secure

it using the safety chain.

Bef

ore

t

he

f

i

rst

i

nst

al

l

at

i

on

al

so

check

t

he

P.

T.

O.

shaf

t

l

engt

h.

Check the P.

T.

O.

shaft l

ength by raising and l

owering the machine to determine the position with the

shortest distance among connecting shafts.

Tubes shoul

d be in this position,

when the P.

T.

O.

shaft is

connected,

app.

20 mm shorter.

In case the P.

T.

O.

shaft is too l

ong,

it must be shortened:

•

Saw of steel

and pl

astic tubes on both ends to the same l

ength.

Afterwards fil

e down,

cl

ean and

grease

the edges.

RCA

320-2

:

P.

T.

O.

shaft must be connected to the machine as perpendicul

ar as possibl

e! Therefore,

it is recommended the

machine is connected to the three point tractor system,

during the operation.