19

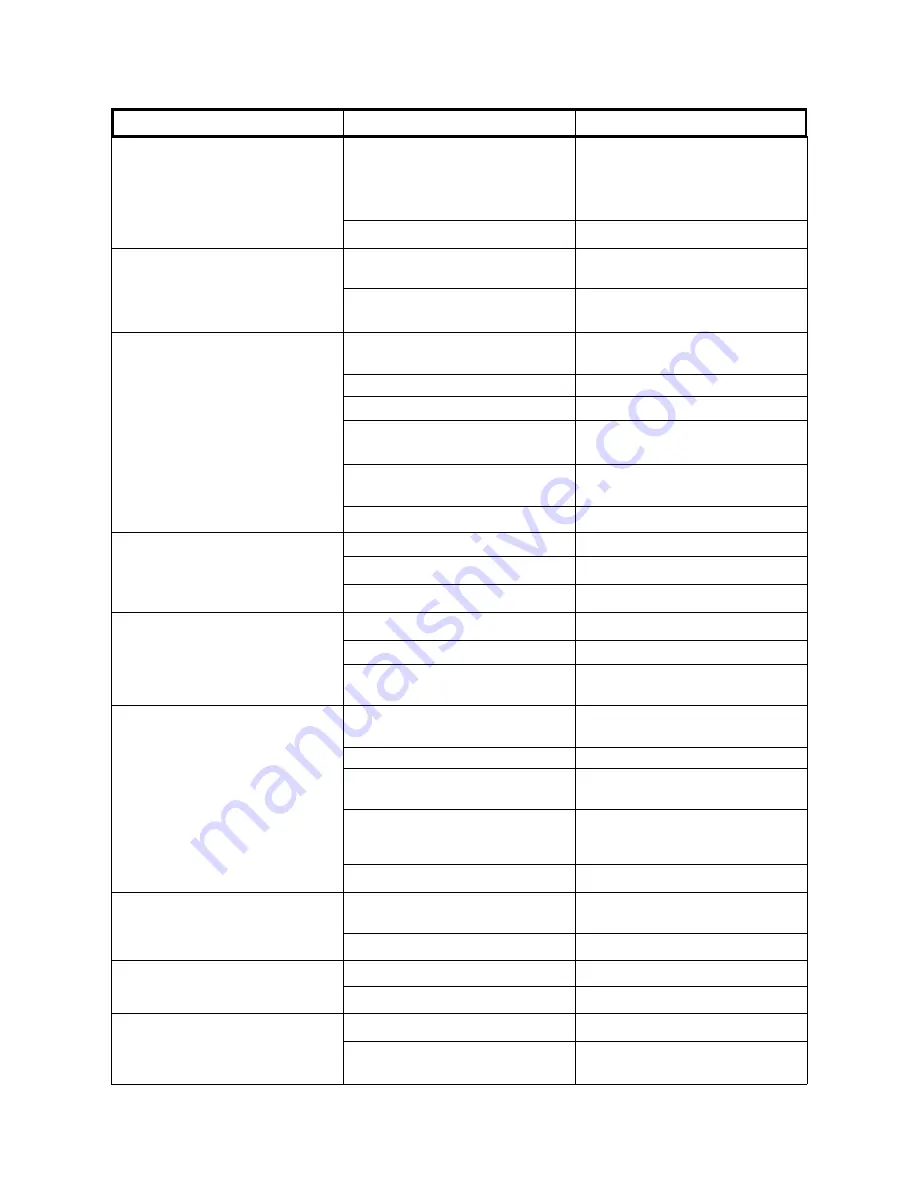

5.8 TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSES

SOLUTION

The machine does not react to movements

of the sawbar activation handle

Check the machine drive (P.T.O. shaft or

electric motor must be connected and in

operation, otherwise the pump and

chainsaw drive do not work)

Check the level of the oil in the tank

Damaged control mechanism

Repair or replace the control mechanism

⊗

Electric motor does not start or it often

shuts down (RCA 320-2 E)

Damages to power cables or blown fuses

Check the power cables, install the approp-

riate fuses

Motor protection is shutting the motor

down.

Power cable size is not appropriate, the

machine is overloaded

Hydraulic oil is overheating

Not enough oil in the reservoir

Check the oil level and add more if

necessary.

Worn-out hydraulic oil

Change the hydraulic system oil.

Clogged oil filter

Clean the oil filter. (5.5)

Clogged hydraulic pipes

Check the hydraulic pipes and clean them if

necessary.

Splitting cylinder did not reach the final

position.

Reverse the cylinders, clean the splitting

chute

High Outside Temperature

Install the oil cooler

Machine is loosing power

Hydraulic oil is overheating

Refer to “ Hydraulic oil is overheating“

Not enough oil in the reservoir

Check the oil level and add more if

The machine is overloaded

Remove the overloading causes

Excessive power consumption during

sawing

The chain is dull

Sharpen or replace the chain

The chain is not properly tensioned

Tension the chain

The chain is covered with resin

Clean the chain using the solvent (i.e. Nit-

ro-Solvent) or replace the chain

Louder operation of the machine

Revolution speed of the tractor is exceeded

(RCA 320-2)

Consider the recommended revolution

speed.

Clogged filter

Clean the filter

Not enough oil in the reduction gear

Check the oil level and add more if

necessary.

The machine is not connected to the tractor

– only P.T.O. shaft is connected

(RCA 320-2)

Connect the machine to the tractor or posi-

tion the tractor

perpendicular

to machine

P.T.O. shaft is not lubricated

Lubricate P.T.O. shaft appropriately

Hydraulic hoses are overheating

Not enough oil in the hydraulic system

Check the oil level and add more if

necessary.

Worn-out hydraulic oil

Replace the hydraulic system oil. (**)

Hydraulic cylinder is leaking

Seals are worn-out

Replace worn-out seals.

Damaged piston-rod

Replace the cylinder

In-feed conveyor is slipping or not opera-

ting

Conveyor belt is not tensioned enough

Tension the conveyor belt

Not enough oil in the hydraulic system

Check the oil level and add more if

necessary.