22

More demanding procedures must be performed by a qualified technical service only.

(**) In worse operating conditions with high temperatures of the environment we recommend installation of oil cooler.

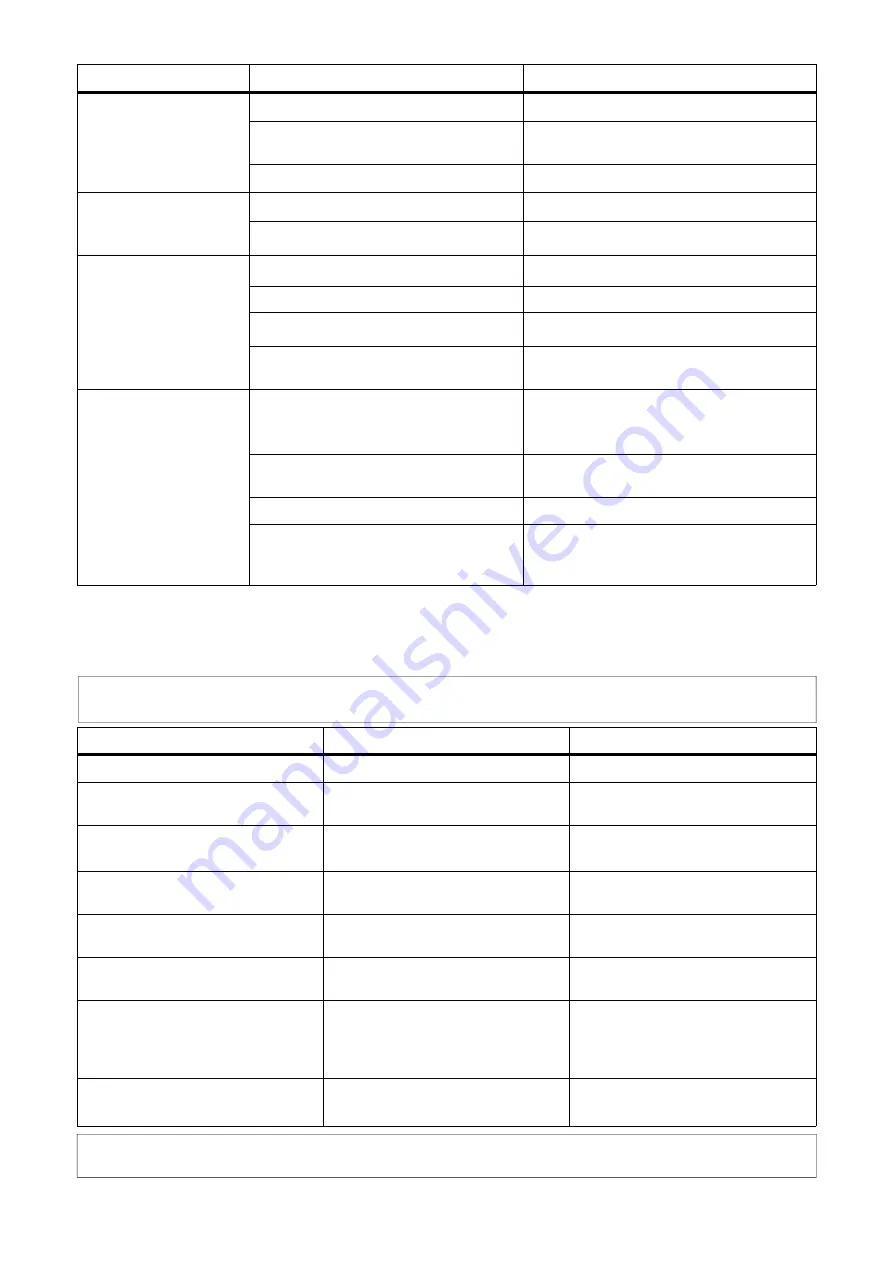

PROBLEM

POSSIBLE CAUSES

SOLUTION

In-feed conveyor is not

generating enough pull,

although low pressure

gauge shows 90 bars

during its operation.

Conveyor belt is not tensioned enough

Tension the in-feed conveyor belt

Incorrect installation of the conveyor belt

Check the placement of the supporting foot

(Chapter: 4.2.)

The chain is not lubrica-

ting

The machine ran out of chain lubrication oil Add chain lubrication oil

Lubrication system is clogged or damaged Check the lubrication system

Discharge conveyor is not

operating

Conveyor belt is not tensioned enough

Tension the conveyor belt

Not enough oil in the hydraulic system

Check the oil level and add more if necessary

Speed regulator is fully screwed down

Set the speed regulator appropriately

Inappropriate rotating speed of the P.T.O.

shaft + worn cutting chain

Replace the belt (Chapter: 5.10.), replace the

cutting chain (Chapter: 5.1.). Increase the rota-

ting speed of the P.T.O. shaft (Chapter: 3.2.).

Cutting chain is not properly tensioned

Replace the belt (Chapter: 5.10.), tension the

cutting chain properly (Chapter: 5.2.)

Belt is not properly tensioned

Replace the belt (Chapter: 5.10.)

Excessive force on the operating handle

during cutting

Replace the belt (Chapter: 5.10.), (Chapter:

4.3.), check the cutting chain and use lower

force on the operating handle.

Torn cutting chain drive

belt

The log too heavy or jammed

Position or cut the log – shorten the log

Stuck wood is preventing the conveyor belt

from moving.

Clean the conveyor belt area – stop the machi-

ne during cleaning procedure.

5.9. MAINTENANCE PLAN

The machine must be turned off (the P.T.O. shaft must be disconnected from the tractor), while performing any

service and maintenance procedures!

WHAT?

WHEN?

HOW?

Check the tension of the cutting chain Before each use

Chapter: 5.2.

Check the tension of the cutting chain

belt

Every 50 hours of operation

Chapter: 5.10.1.

Tighten any loose bolts and nuts and

hydraulic connections

After first hour of operation

After every 100 hours of operation

Using appropriate tools

Check the oil level

(hydraulic & bar oil levels)

Before each use

Visually

Hydraulic system oil change

First after 5000 hours of operation,

afterwards once every two years

Chapter: 5.4.

Cleaning the oil filter

During the oil change or in case the

gauge indicator is in the red zone

Clean the filter with gasoline and blow

it with compressed air from inside out.

Multiplication gear oil change

(RCA 380)

After the first 50 hours of operation

Later, after every 1000 hours of

operation

Drain the oil in the appropriate vessel

from the lowest plug and replace the

plug. Fill the oil through the upper

plug.

Cleaning and replacing the air filter on

the saw drive

Cleaning the filter - daily

Replacing the filter - every 6 months

Chapter: 5.10.2.

Regularly remove all wood remains and sawdust from the splitting channel, under the conveyor belt, under

the lifting mechanism of the Splitting Wedge and under Sawbar Activation Handle!

Summary of Contents for RCA 380

Page 5: ...5 ELECTRIC POWER UNIT EP 12 Tajfun Motor Power 11 kW Weight 211 kg EP 12 ...

Page 12: ...12 7 H P 6 A 11 12 10 ...

Page 30: ...30 ...

Page 31: ...31 ...