14

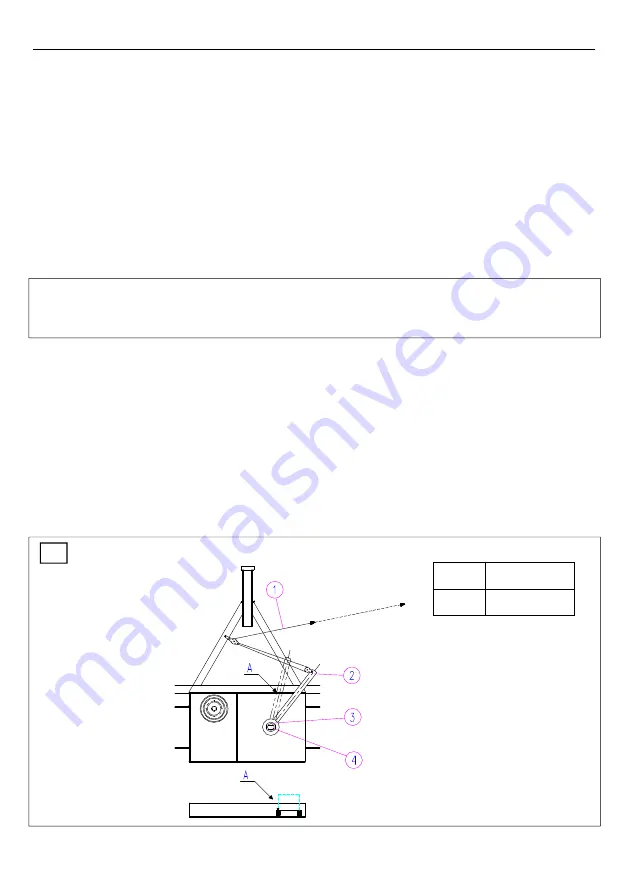

4.6. SETTING THE WINCH PULLING POWER

(Figure 8)

Each winch is factory set to its

maximum

pulling power which is also specified on the winch

type plate. Increasing of the pulling power over this value is

not allowed

. After the pulling

power of the winch decreases due to the wear of clutch linings, the clutch must be readjusted.

Pulling power setting procedure:

Disconnect the PTO shaft and shut down the tractor.

Use the spanner No 30 to release the safety plug

4

on the drum axis by turning it to the

left.

Use the spanner No 50 to turn the nut

3

M40 to the right so that you can pull the string

1

,

by using force “F” to move the clutch handle

2

to the end of the groove

A

.

Screw the safety plug

4

tightly to prevent the nut M40 from releasing.

It is important to tighten the nut M40 only so tight, that you can still pull the clutch

handle 2 to the end of the groove A using the force “F” and reach the nominal pulling

power (See Chapter: 4.2.)!

By proper adjustment of nut

M40

, set the nominal pulling power.

If the nut

M40

is set too tightly, you cannot move the handle

2

to the end of the groove and

pulling power decreases. If the nut

M40

is set too loose, it causes excessive deviation of

the drum, which can cause falling of the clutch plates off it’s pins. If this happens, the

whole drum must be dismantled.

»F«

35 A

250 N

8