16

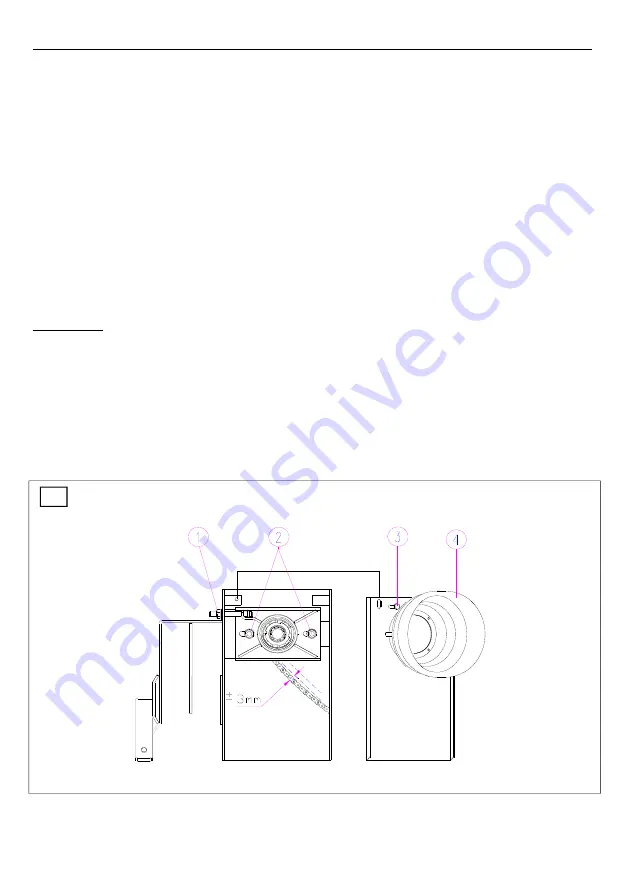

4.8. CHECKING AND TIGHTENING THE DRIVE CHAIN (Figure 10)

During the operation and under the load, the drive chain stretches, therefore the operator

must check and readjust the chain periodically to prevent excessive wear of the whole chain

drive. The chain must not be set to tight and chain slack should be set to ±3 mm. Check the

tightness of the chain by hand, pushing the chain between the chain wheels.

Lubricate the chain using special chain lubrication spray.

Procedure :

If the winch is connected to the tractor, shut down the tractor and disconnect the PTO shaft

Unscrew the screw

3

and remove the chain cover

4

by pushing it upwards.

Loosen both nuts

2

by approximately one turn

Tighten the drive chain, by screwing the nut on the tightening screw

1

until you reach the

desired chain slack: ±3 mm

Screw the nuts

2

tightly

Install the chain cover and fasten it using the screw

3

.

10