39

Chapter 3 How to Perform Embroidery

3

Resuming embroidery

Press the [START] button on the operation panel.

Embroidery resumes from the paused position.

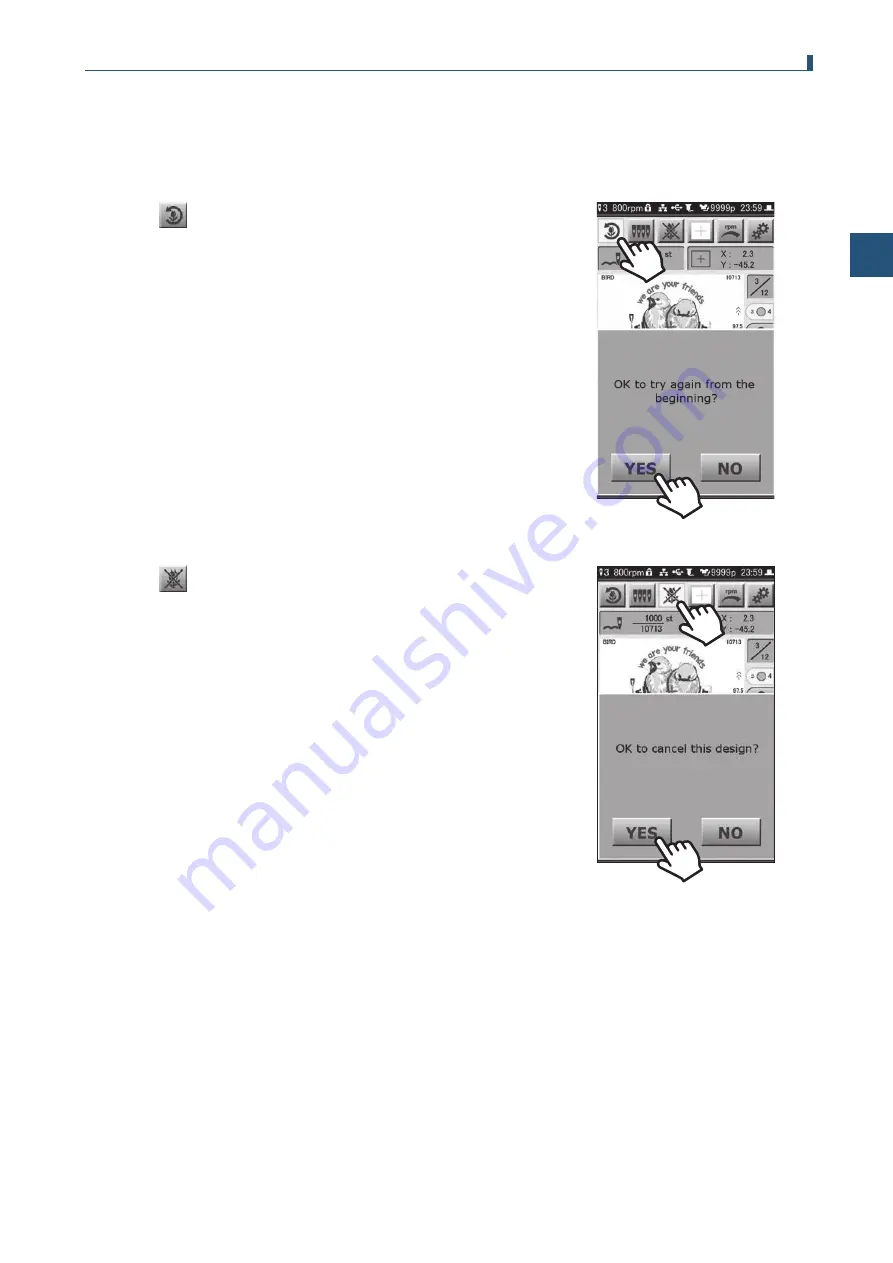

Starting the embroidery again from the beginning

Tap

, and then tap [YES].

Thread is trimmed automatically, and embroidery is stopped. Also,

you are returned to the Embroidery Start screen.

Ending the embroidery

Tap

, and then tap [YES].

Thread is trimmed automatically, and embroidery is stopped. And,

you are returned to the Home screen.