CHAPTER 10 ELECTRO-COMPONENT PARTS

104

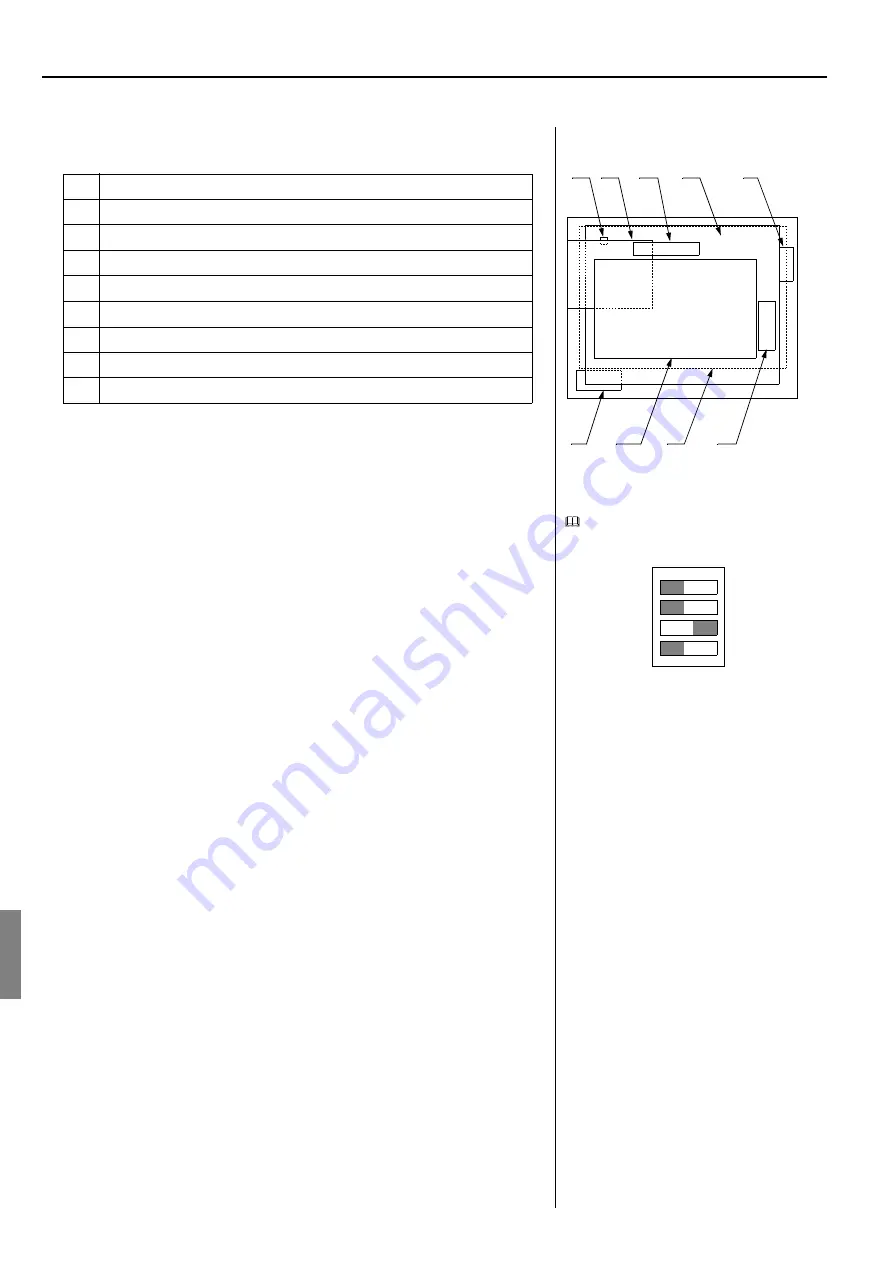

3. OPERATION PANEL BOX

Do not change setting of the DIP switch.

1

DIP switch (SW1)

2

FDD

3

Backlight inverter

4

CPU-E card

5

Touch panel cable extension card

6

Frame travel switch card

7

RISC card

8

Touch panel

9

Regulator card

(GC02)

4

2

5

3

7

8

[Rear view]

9

6

1

OFF

ON

1

2

3

4

DIP switch [SW1]

Summary of Contents for TFHX Series

Page 14: ...CHAPTER 2 MACHINE CONSTRUCTION 7 CHAPTER 2 MACHINE CONSTRUC TION GC07...

Page 22: ...CHAPTER 3 OPERATION BASICS 15 CHAPTER 3 OPERATION BASICS GC02...

Page 33: ...CHAPTER 3 OPERATION BASICS 26...

Page 34: ...CHAPTER 4 DATA SET 27 CHAPTER 4 DATA SET GC02 Free Space...

Page 39: ...CHAPTER 4 DATA SET 32...

Page 40: ...CHAPTER 5 EMBROIDERY SETTING 33 CHAPTER 5 EMBROIDERY SETTING GC02 1 2 3 1 2 3...

Page 56: ...CHAPTER 6 DESIGN DATA MANAGEMENT 49 CHAPTER 6 DESIGN DATA MANAGE MENT GC02...

Page 71: ...CHAPTER 6 DESIGN DATA MANAGEMENT 64...

Page 72: ...CHAPTER 7 MANUAL OPERATION 65 CHAPTER 7 MANUAL OPERATION GC03 Xa 43 2 Ya 276 1...

Page 85: ...CHAPTER 7 MANUAL OPERATION 78...

Page 102: ...CHAPTER 9 OUTLINE OF FUNCTIONS 95 CHAPTER 9 OUTLINE OF FUNCTIONS GC02...

Page 108: ...CHAPTER 10 ELECTRO COMPONENT PARTS 101 CHAPTER 10 ELECTRO COMPONENT PARTS GC02...

Page 112: ...CHAPTER 11 TROUBLESHOOTING 105 CHAPTER 11 TROUBLESHOOTING GC02 228...

Page 118: ...CHAPTER 12 MAINTENANCE 111 CHAPTER 12 MAINTENANCE GC02...

Page 124: ...TERMINOLOGY TERMINOLOGY FD11...

Page 131: ...TERMINOLOGY...

Page 132: ...ELECTRO RELATIVE DRAWING ELECTRO RELATIVE DRAWING GC02...

Page 139: ...ELECTRO RELATIVE DRAWING...