45

Page

The manufacturer recommends having the water heater checked once a year or as necessary by a licensed

technician. If repairs are needed, any repairs should be done by a licensed technician.

UNIT DRAINING AND FILTER CLEANING

Satisfactory

Blue flame

Unsatisfactory

Flame

blowing up

Unsatisfactory

Red or Yellow

flame

Water valve

Gas

valve

Drain plug

(Small)

Drain plug

with Filter (Large)

Normal Operation

Owner's Guide

-Measuring inlet gas pressure-

1. Turn off all electric power to the water heater if service is to be performed.

2. Turn the manual gas valve located on the outside of the unit to the off position.

3. Failure to follow these steps could lead to fire or explosion, resulting in personal injury

or death.

WARNING

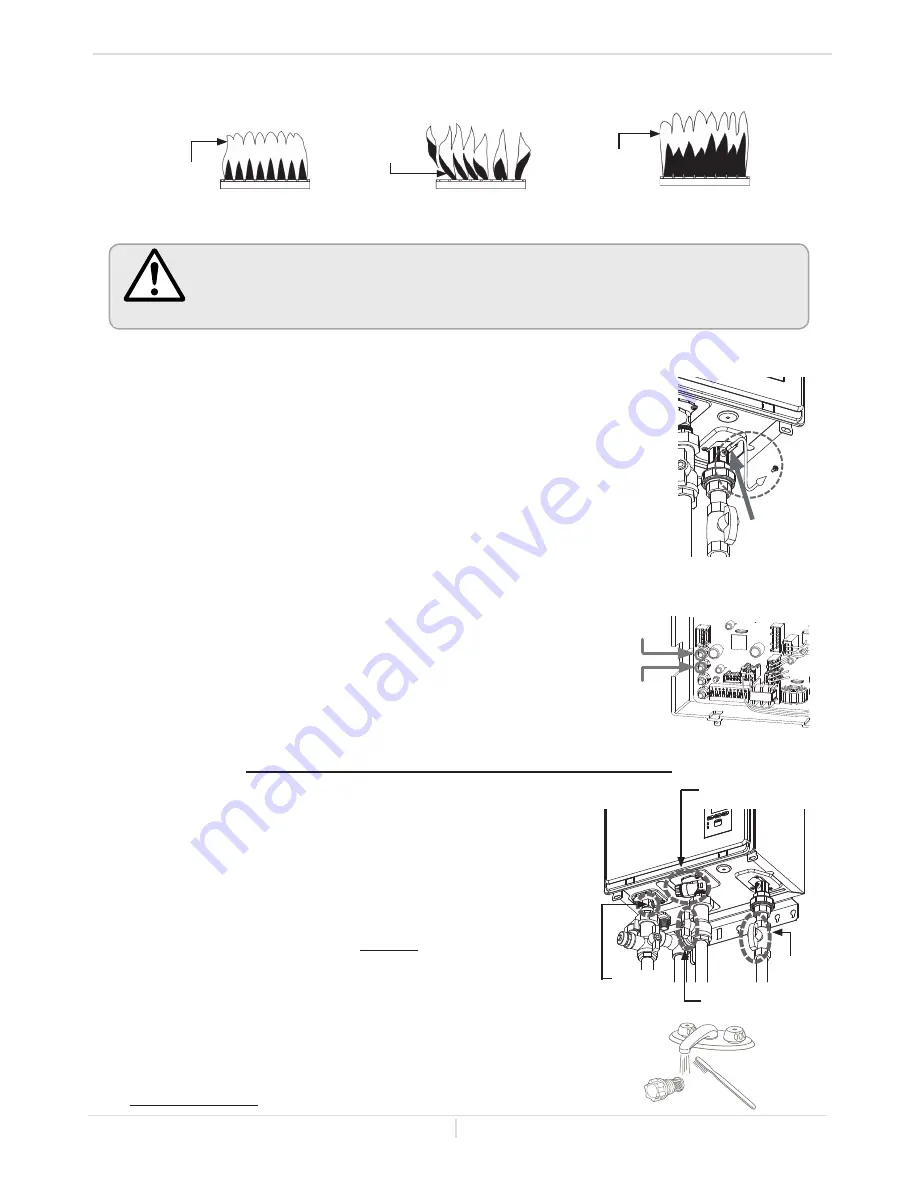

The water heater cannot perform properly without sufficient inlet gas pressure. Below are instructions

on how to check the inlet gas pressure.

THIS IS ONLY TO BE DONE BY A LICENSED PROFESSIONAL

.

1.

Shut off the manual gas valve on the gas supply line.

2.

Remove the screw from the pressure port which is located on the gas inlet of

the water heater shown in the diagram on the right.

3.

Connect the manometer to the pressure port and zero the manometer.

4.

Re-open the manual gas valve. Verify that there are no gas leaks.

5.

With all gas burning equipment off, take a reading of the static gas pressure and

make a note of it.

6.

Measure gas supply pressure at maximum heater operation: Open hot water

faucets to create maximum flow. Press the MAX button on the computer board.

(Refer to the diagram below.) Take a reading of the supply dynamic gas pressure

with all gas burning equipment running at maximum rate.

7.

The static and dynamic pressures should be within the ranges specified on the

heater's rating plate and the table on p. 28

8.

The difference of static to dynamic pressure should not exceed 1.5"

W.C. Pressure drops that exceed 1.5" W.C. can indicate restricted gas

flow, undersized gas lines, and/or undersized supply regulators.

9.

Measure gas supply pressure at minimum heater operation: Reduce

water flow so the heater is running at minimal operation. Press the

MIN button on the computer board. (Refer to the right diagram.) Take

a supply gas pressure reading and verify that it is within the specified

inlet gas pressure range.

Pressure

port

1. Close the manual gas shutoff valve.

2. Turn off power to the unit and wait a couple of seconds. Turn on

again.

3. Wait 30 seconds, and then turn off power to the unit.

4. Close the

inlet

water valve.

5. Open all hot water taps in the house. When the residual water flow

has ceased, close all hot water taps.

6. Have a bucket or pan to catch the water from the unit’s drain plugs.

If Isolation valves are installed, open the drains to drain the water. If

isolation valves are not installed,

unscrew

the two drain plugs (large

and small) to drain all the water out of the unit. Do not lose the

o-rings that will be on the two drain plugs.

7. Wait a few minutes to ensure all water has completely drained from

the unit.

8.

Clean the filter

: Check the water filter located within the cold inlet.

With a tiny brush, clean the water filter of any debris which may have

accumulated and reinsert the filter back into the cold water inlet.

9. Securely screw the drain plugs back into place.

Hand- tighten only

.

Computer board

MAX

button

MIN

button