INS

TALLA

TION

12

On-Demand Water Heater Installation Manual and Owner’s Guide

INSTALLATION

Installation environment

Warning! Do not store or use flammable

materials, vapors, or liquids in the same location

where this water heater is installed.

Before installing the water heater, ensure that it will be

located as described on p. 8 through 10. In addition to that,

the following factors shall be taken into account for the

installation location and method. Refer to each section in

the installation manual.

Atmosphere temperature

Install the water heater in a heated area where below

freezing temperature cannot occur. Units installed in areas

subject to below freezing temperature MUST follow the

steps outlined on p. 49. The pipe cover or recess box is

recommended when the water heater is installed outdoors

because it provides better protection from the elements.

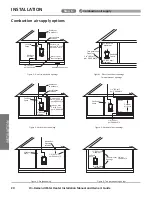

Combustion air supply

The water heater requires fresh combustion air should be

free of corrosive elements and flammable vapors. If it is

installed at the contaminated area or in a confined area,

direct venting installation is recommended. (Refer to pp. 17

to 25.)

Proper ventilation

For proper operation the water heater must be vented in

accordance with the section “Venting of Equipment” of the

current edition of the National Fuel Gas Code: ANSI Z223.1/

NFPA 54 in the United States and/or Section 8 of the B149.1

Natural Gas and Propane Installation Code in Canada, as well

as applicable local building codes. (Refer to pp. 14 to 30.)

Proper mounting and clearance

The water heater shall be securely mounted on wall that

can support the weight of the water heater. A wall mounting

bracket is supplied with the water heater to securely mount

the water heater to wall studs. (Refer to p. 13.) The water

lines, gas line, condensate drain line, and pressure relief

valve discharge line shall be supported using field supplied

pipe hangers. The water heater shall not bear the weight of

these lines. The water heater requires proper installation

clearance for operation and service as described in the right.

Condensate Drain line

The condensate produced is acidic. Drain the condensate in

accordance with all local codes and common safety practic-

es. (Refer to p. 44.)

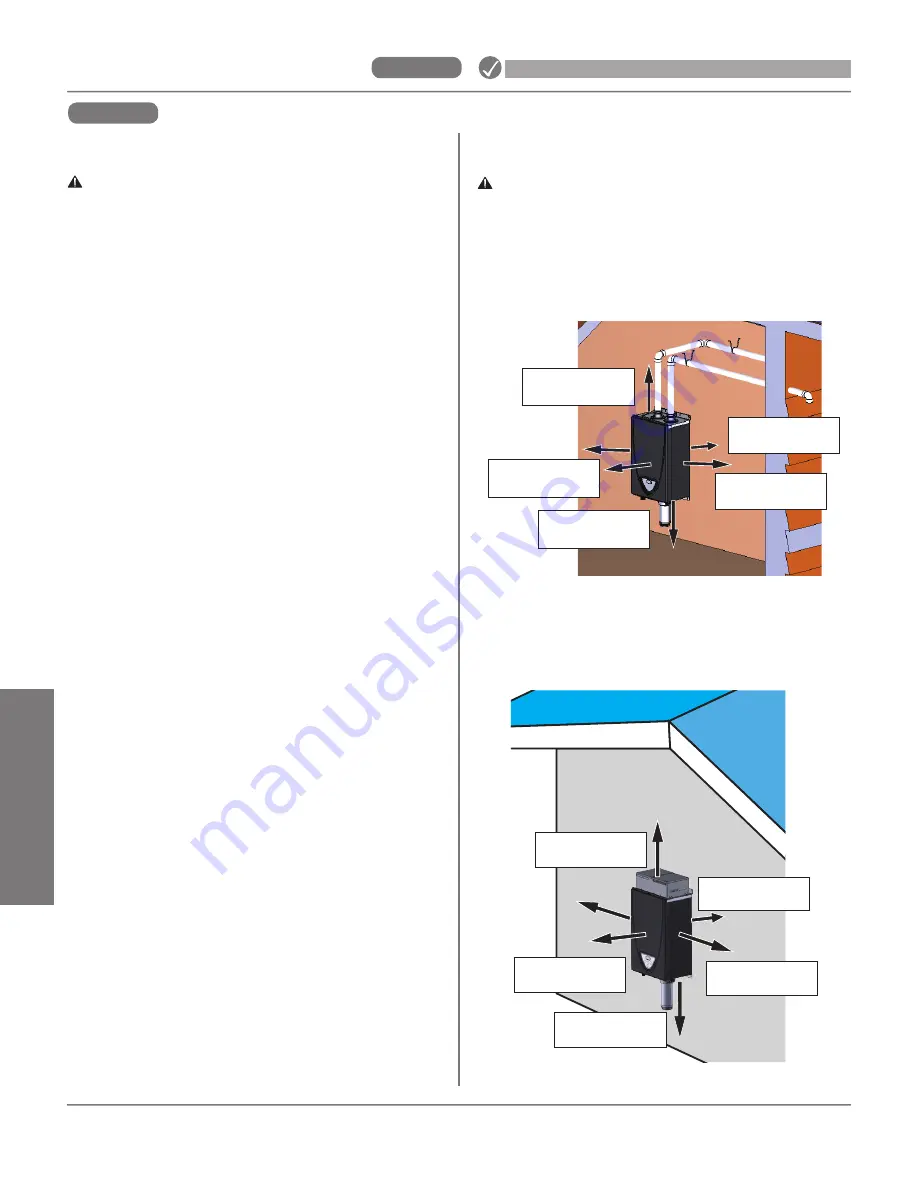

Unit clearances

Warning! Maintain all clearances around the

water heater. Failure to do so could create a

fire hazard, potentially leading to death, serious

injury, and/or property damage.

Indoor

T

op:

12 in (305 mm)

Front

:

4 in (102 mm)*

Back

:

0.5 in (13 mm)

Side

3 in (76 mm)

Bottom

:

18 in (458 mm)

*24 inches (610 mm) recommended for maintenance.

Outdoor

T

op:

36 in (914 mm)

Front

:

24 in (610 mm)

Back

:

0.5 in (13 mm)

Side

3 in (76 mm)

Bottom

:

18 in (458 mm)

Step 3:

Installation environments and unit clearances

Step 3:

Installation environment and unit clearances

Summary of Contents for 160X3P

Page 84: ...7J8071 1 2000570774 REV B...