17

Page

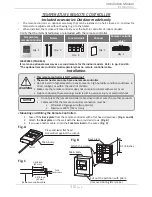

Calculate minimum size of vent openings and ducts

The vent cross-sectional area needed to provide the free area depends on the covering on the vent openings. Typical

vents use louvers or grilles to protect the opening. The louver or grill itself blocks some of the free area, so the open-

ing may need to be larger to meet the minimum free area requirements.

Use the following formula to calculate the required cross-sectional area:

Cross-sectional area = minimum free area required ÷ percent free area of covering (in decimals – e.g., 60% = 0.6)

For example, an installation area that requires openings with 100 square inches of free area would need

134 square inch openings if using metal louvers rated at 75% free area (100 sq. in. ÷ 0.75 = 134 sq. in.).

If you do not know the % free area for your louver or grill, use the following values:

• For wood louvers or grilles: 25%

• For metal louvers or grilles: 75%

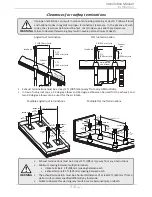

Follow these rules to ensure that vents and ducts provide adequate air flow:

•

Each vent opening must be no smaller than 100 square inches .

• Ducts must have the same cross-sectional area as free area of the opening.

•

Rectangular ducts must have a minimum dimension of no less than three inches .

•

All screens must have mesh ¼” or larger.

• Moveable louvers must be locked open or interconnected with the equipment so that they open automati

-

cally during operation.

• Keep louvers and grills clean and free of debris or other obstructions.

Check that air source is clean and free of chemicals

Air for combustion and ventilation must be clean and free of corrosive or flammable chemicals. A failure due to cor

-

rosive chemicals in the air is not covered by the warranty. Combustion air must be free of acid-forming chemicals such

as sulfur, fluorine, and chlorine. Be sure that air at the vent inlets is free of such chemicals.

See graphics on next page.

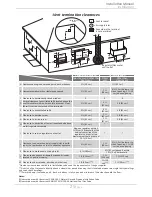

Table 1

Minimum Free Area of Permanent Openings for Ventilation and Combustion Air Supply – Air from outdoor or

indoor spaces.

Based on the total BTU/h input rating for all gas burning appliances within a confined space.

Opening Source

Minimum Free Area

Direct to outdoors*

1 sq. in. per 4,000 BTU/hr (see Figure

1, 2

)

Vertical ducts

1 sq. in. per 4,000 BTU/hr (see Figure

3

)

Horizontal ducts

1 sq. in. per 2,000 BTU/hr (see Figure

4

)

Single Opening

1 sq. in. per 3,000 BTU/hr (see Figure

5

)

Two permanent openings

to another room**

1 sq. in. per 1,000 Btu/hr (see Figure

6

)

Opening: 100 in.

2

MIN.

Minimum dimension of air openings:

no less than 3 in.

*These openings connect directly with the outdoors through a ventilated attic, a ventilated crawl space, or through

an outside wall.

** For direction on combining spaces in different stories within the structure, refer to the current edition of the

National Fuel Gas Code ANSI Z223.1/NFPA 54.